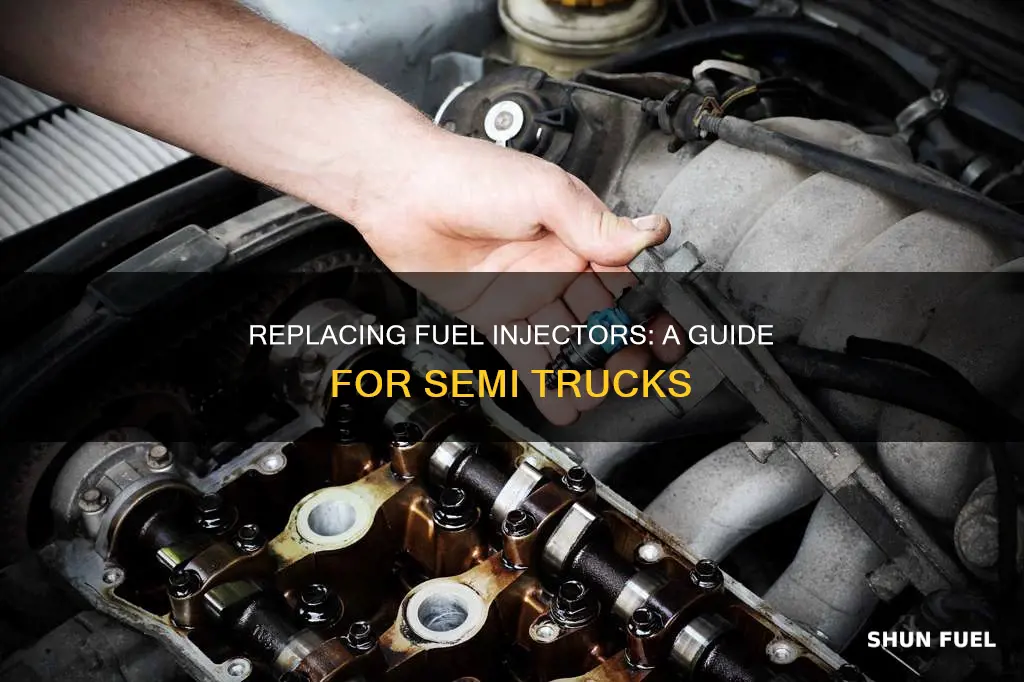

Replacing the fuel injector on a semi-truck is a delicate task that requires careful attention to avoid contamination and damage. The process involves preparing the service area and tools, removing the old injectors, cleaning the engine, installing the new injectors, securing them in place, and resetting codes. It is important to follow manufacturer recommendations and take precautions to avoid common issues such as water in the fuel, clogged fuel filters, and coolant mixing with oil.

| Characteristics | Values |

|---|---|

| When to change fuel injectors | Fuel injectors are designed to last at least 500,000 miles. |

| How often to change fuel injectors | Fuel injectors typically have life cycles of 500,000 to 750,000 miles. |

| Who changes fuel injectors | The task of replacing fuel injectors falls to second and third vehicle owners, and the service providers they rely on. |

| Tools needed | Specialty tools designed for injector replacements, multi-use torque wrenches, pry bars, wrenches, etc. |

| Preparation | Prepare your service area by ensuring it is spotless to prevent contamination. Only unbox new injectors when ready to install. |

| Removal process | Disconnect the battery supply, remove the keys from the ignition, and carefully follow truck and engine OEM recommendations. |

| Cleaning | Clean the engine and the injector cylinders, removing any fuel, water, or other contaminants. Replace tip gaskets and old gaskets with clean, fresh replacements. Wipe away any dirt, grime, or debris near the cylinders or on the injector clamps. |

| Installation | Lubricate the new injectors in advance and delicately press them into each cylinder by hand, guiding the component carefully to avoid damage. |

| Securing | Use a hold-down clamp and a specialty torque wrench to torque the bolt to ensure proper torque and torque angle. |

| Additional steps | Follow manufacturer recommendations during injector installation and securement. Replace O-rings and ensure proper reinstallation of all components. |

| Final steps | Add the specialized TRIM codes that come with the new injectors into the engine's electronic control module (ECM). Run the engine at idle for at least 20 minutes to ensure proper functioning. |

What You'll Learn

Prepare your service area

Having a spotless service area is essential when replacing fuel injectors. Contamination is the leading cause of premature fuel injector failure, and it can occur at many points during installation. Ideally, you should not open the new injector packaging until you are ready to install it. Ensure you have a clean space where you can unwrap and prepare the new injectors for installation.

All the tools required to remove the old injectors and install the new ones should be easily accessible. This includes specialty tools designed for injector replacements and multi-use torque wrenches.

Replacing fuel injectors in a medium- or heavy-duty truck engine can be done in less than a day, assuming you are well-trained and prepared.

Climate Change: Wildfire Fuel and Future Risks

You may want to see also

Remove the old injectors

To remove the old injectors from a semi-truck, first park the truck in a service bay and disconnect the battery. It is important to follow the truck and engine manufacturer's recommendations when removing the injectors, as each design is unique.

Next, begin to remove the covers and assemblies and disconnect the fuel lines. As you do this, clean each component and set it aside for easy reinstallation. Most heavy-duty truck engines feature a unit injector system, while common rail systems are typically found in medium-duty engines.

If the injector has failed prematurely, it is a good idea to identify the root cause to prevent the same issue from occurring with the new injector. Once all the necessary components have been removed, you can move on to cleaning the engine and preparing for the new injectors.

Removing the old injectors can be challenging, and you may need to use some force or special tools. You can try using a hooked seal puller, a slide hammer, or two small pry bars to gently work the injectors out. Be careful not to bend or break anything during this process.

Replacing Fuel Water Separator Filter: Step-by-Step Guide

You may want to see also

Clean engine and prepare new injectors

To clean the engine and prepare new injectors, you must first ensure that the engine and service area are clean. Each injector cylinder must be cleaned and purged, removing any fuel, water, or other contaminants. Tip gaskets that sit within the cylinder should be removed if they did not come out with the old injector. Any dirt, grime, or debris near the cylinders or on the injector clamps should be wiped away, and the old gaskets should be replaced with clean, fresh ones. The seating area for the injector and the hold-down bolts must be clean.

Once the engine is clean, it is time to prepare the new injectors. Each component should be carefully removed from its packaging and lubricated in advance of installation. New injectors should be delicately pressed into each cylinder by hand. As an injector is moved into place, it should be carefully guided to ensure the injector tip doesn't encounter anything that could cause damage. Injector nozzle tips are microscopically small, so it doesn't take much contact or contamination to impact their functionality.

Changing Fuel Filter on Husqvarna Lawn Mower: Step-by-Step Guide

You may want to see also

Install the new injectors

To install the new injectors, first carefully remove them from their packaging and lubricate them. Next, gently press the new injectors into each cylinder by hand, being careful to avoid any damage to the injector tip. Injector nozzle tips are microscopically small, so it doesn't take much contact or contamination to impact their functionality. Once the injectors are in place, secure them with a hold-down clamp and lock them into the cylinder. Use a specialty torque wrench to torque the bolt of the hold-down clamp to ensure proper torque and torque angle.

Different engines and injector systems may require additional steps or components to be replaced. For example, O-rings should be replaced during the remanufacturing process, as they can become damaged during installation. Make sure to follow manufacturer recommendations during injector installation and securement.

After the new injectors are properly installed, reconnect the fuel lines and reposition assemblies, covers, and other related components. It is important to ensure that all components are properly reinstalled to avoid any issues. Finally, add the specialized TRIM codes that come with the new injectors into the engine's electronic control module (ECM). These codes are essential to ensure the new injectors work correctly, as they relay the specific characteristics of the injectors to the engine.

Changing Fuel Injectors in a Celica: Step-by-Step Guide

You may want to see also

Secure the injectors

To secure the injectors, technicians should use a hold-down clamp to lock the injector into the cylinder. It is important to ensure that the injector fits firmly into the cylinder with minimal effort. A specialty torque wrench should be used to torque the bolt of the hold-down clamp to achieve the proper torque and torque angle. This process helps to lock the injector securely in place and prevent movement or dislodging during engine operation.

Technicians should also be cautious not to use excessive force or a hammer when securing the injectors. The injector nozzle tips are microscopically small, and even minor contact or contamination can impact their functionality. Therefore, a delicate touch is necessary to avoid any potential damage during the installation process.

Additionally, it is crucial to follow the manufacturer's recommendations during injector installation and securement. Different engines and injector systems may require additional steps or component replacements. For example, O-rings, which are replaced during the remanufacturing process, can become damaged during installation if not properly aligned.

By carefully securing the injectors and following the necessary steps, technicians can help ensure the proper functioning of the injectors and prevent potential issues or failures down the road.

Replacing Fuel Pump in 2010 F150: Step-by-Step Guide

You may want to see also

Frequently asked questions

Before starting, ensure you have a spotless service area to work in. It is also important to have the right tools to hand, including specialty tools designed for injector replacements and multi-use torque wrenches.

Disconnect the battery supply and carefully follow all truck and engine OEM recommendations. You will then need to remove covers and assemblies and disconnect fuel lines.

Clean the engine and prepare the new injectors. Each injector cylinder must be cleaned and purged, removing any fuel, water or other contaminants. Tip gaskets should also be removed and replaced with clean, fresh replacements.

New injectors should be delicately pressed into each cylinder by hand. Ensure that the injector tip doesn't encounter anything that could cause damage.