Holley's EFI system is a self-tuning fuel injection system that uses a variety of methods to determine appropriate fuelling. The three main methods are Speed Density, Mass Airflow, and Alpha-N. Speed Density and VE-Based Tuning are used by many aftermarket engine management systems, especially in racing. VE-Based Tuning is used in Holley's Sniper and Terminator X products as the base calibration style. Volumetric efficiency calculations are key to the Sniper system's performance. These calculations use the engine's size and manifold air temperature to calculate the amount of fuel required to reach the targeted air/fuel ratio. The user answers several questions about the engine, and the system optimises itself based on these responses.

What You'll Learn

Understanding the relationship between the AFR, Learn and Base Fuel Tables

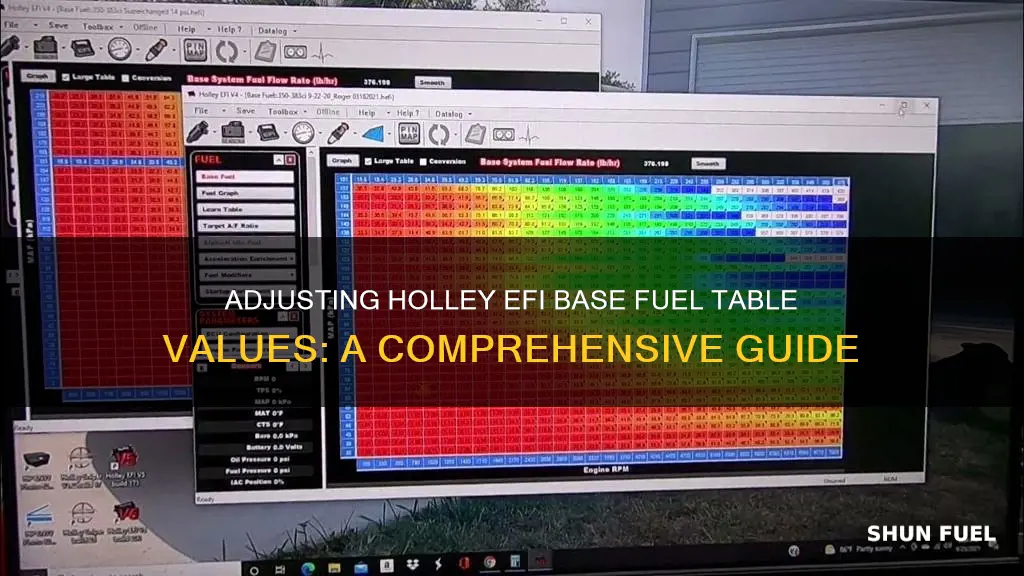

The AFR, Learn, and Base Fuel Tables work together when tuning. The Learn Table is a modifier of the Base Fuel Table. The Learn Table values are directly applied to the Base Fuel Table, indicating how much the Base Fuel Table has been altered. The Base Fuel Table values don't change unless you transfer learning to the base, which then allows you to blend the Fuel Graph so it's smooth. The Learn Table itself contains constantly changing values. When the Learn Table values stop making significant changes, the ECU is finished self-tuning.

The purpose of the Learn Table is not to achieve similar values, high/low values, or any value in particular. It's simply indicating the amount of tuning applied to the Base Fuel Table. The Base Fuel Table doesn't change its displayed values unless you transfer learning to the base. However, it is always in a modified state because the Learn Table values are applied to it. Closed Loop and Learning happen in "real time", but only the Learning is saved.

The AFR target map is used for closed-loop operation. In closed-loop operation, feedback from the O2 (Lambda) sensor is used to adjust the value from the fuel map to reach the AFR target. When not in closed-loop mode, the amount of fuel delivered comes from the fuel map. The AFR target map is a table that you create to represent the air-to-fuel ratio you would like your engine to run. The Fuel Map is the table you then tune to calibrate the EFI system to deliver the amount of fuel required to reach the targets you've entered in the AFR map.

Replacing the Fuel Pump in a 2005 Chevy Impala

You may want to see also

How to adjust the Base Fuel Table

To adjust the Base Fuel Table, you can either build a base tune from scratch or tweak one of the base tunes provided by Holley. Here is a step-by-step guide on how to adjust the Base Fuel Table:

- Choose a Base Tune: If you are a beginner, it is recommended to start with a base tune provided by Holley and make adjustments from there. Holley has included various base calibrations that can be loaded into the ECU, which you can find in the Help menu under "Base Calibration Information". Choose the base tune that most closely matches your engine specifications.

- Open the Holley EFI Software: Launch the Holley EFI software and open the Global Folder that contains your chosen base tune. It is recommended to make a copy of this folder before proceeding to prevent any accidental changes to the original tune.

- Set Your Preferences: Go to the Toolbox menu and select Preferences. Here, you can set your preferred units for MAP readings (PSIA or kPa) and select your ECU type if using an HP EFI system.

- Configure System Parameters: Click on the System ICF icon and adjust the settings in the SYSTEM PARAMETERS box. This includes changing the Engine Displacement, Fuel Type, Wideband Oxygen Sensor, Number of Sensors, and Fuel System Type.

- Set Ignition Parameters: Click on the Ignition Parameters tab and adjust the settings according to your engine configuration. This includes selecting the Ignition Type, Sensor Type, TDC Tooth Number, CAM SENSOR type, OUTPUT SETUP type, CRANKING PARAMETERS timing, and MAIN OVER-REV REV LIMITER.

- Enable Closed Loop and Base Fuel Learn: Click on Closed Loop/Learn in the SYSTEM PARAMETERS box. Enable Closed Loop and click on the Learn Parameters box. Select Base Fuel Learn Enabled and leave the Base Fuel Learn Gain at 100% for now. Save your changes before proceeding.

- Verify Sensor Settings: Click on the Sensors ICF Icon to verify that the sensor settings match your engine configuration. Pay close attention to the MAP sensor settings, as it is crucial for accurate fueling calculations.

- Modify Target Air/Fuel Ratio Table: Click on the Fuel ICF Icon and adjust the Target Air/Fuel Ratio Table to match your desired air/fuel ratio for idle and cruise (drivability) areas. You can change multiple cells at once by clicking and dragging, then typing in the new value. Remember to round up to the nearest tenth to make the mixture leaner and round down to make it richer.

- Adjust Idle Speed: Click on the Idle ICF icon and adjust the idle speed to your desired RPM. You can either enter the values manually or use the yellow boxes to adjust the settings.

- Set Base Timing Table: Click on the Spark ICF icon and modify the Base Timing Table according to your engine's requirements. You can use the data from your previous ignition timing settings as a starting point. Make sure to set the timing for idle, cruise, and WOT to ensure optimal engine performance.

Once you have completed these steps, you can save your adjustments and load the new tune into your ECU. Keep in mind that further tuning may be required as you test and optimize your engine's performance.

Fuel Injector Electrical Resistance: Temperature Sensitivity Explored

You may want to see also

The role of the Learn Table

The Learn Table is a crucial component of the Holley EFI system, working in tandem with the Base Fuel Table to ensure optimal engine performance. Its primary role is to adapt to changing environmental conditions and engine variables, making real-time adjustments to the fuel delivery system. This adaptability is essential for maintaining the desired air-fuel ratio (AFR) and engine performance, especially when faced with factors such as altitude, temperature, humidity, and fuel quality variations.

The Learn Table functions as a modifier of the Base Fuel Table, with its values being directly applied to the latter. While the Base Fuel Table values remain static unless manually adjusted or updated, the Learn Table is dynamic, constantly changing to compensate for deviations from the target AFR. This process of "self-tuning" involves the Learn Table adding or subtracting fuel to bring the AFR closer to the desired value. For instance, if the Learn Table value changes from -20 to -10, it is adding fuel, whereas a change from 20 to 10 would indicate a reduction in fuel.

The Learn Table also helps protect the engine in the event of a wideband oxygen (WBO2) sensor failure. By limiting the Learned Compensation Limits, the potential corruption of the Learn Table with false values is reduced. This safeguard ensures that even if the WBO2 sensor malfunctions, the engine can continue operating without skewing the Base Fuel Table.

In summary, the Learn Table in Holley EFI systems is a dynamic tool that adapts to changing conditions, modifies the Base Fuel Table, and ensures the engine receives the correct amount of fuel to maintain the desired AFR. Its role is integral to achieving and maintaining optimal engine performance, and its values provide valuable insights for fine-tuning the fuel delivery system.

Hospitals' Climate Impact: Harming While Healing

You may want to see also

Volumetric efficiency calculations

Volumetric efficiency (VE) is a ratio of an engine's actual breathing volume to its displacement. In other words, VE is a measure of how efficiently an engine breathes. It is calculated by dividing the volume of air that an engine breathes (in litres) by its displacement (also in litres). This value can be expressed as a percentage. For example, a 2.0L engine that breathes 1.5L of air per two crankshaft revolutions has a VE of 75%.

VE testing can be a useful diagnostic tool, as it can indicate whether there are any breathing faults in an engine. A VE test can be performed by accelerating at wide-open throttle to near redline in first or second gear and recording the peak RPM and MAF values, along with intake air temperature and altitude. These values can then be input into a VE calculator, which will determine the engine's breathing efficiency.

Interpreting the results of a VE test can depend on the specific engine and its design. For example, a 2-valve pushrod V8 from GM may not breathe very efficiently even when new, so a VE of 80% could be considered decent. On the other hand, a 4-valve Hyundai with variable valve timing and intake tuning should achieve a VE of around 95%. Therefore, while a VE of 80% may be acceptable for some engines, it could indicate a fault in others.

It is important to note that there are many variables that can affect VE, such as altitude, temperature, and humidity. As such, it is recommended to test multiple vehicles in the same area to establish a baseline for what to expect from the test results.

VE calculations can be a valuable tool for diagnosing and fixing issues with a vehicle's engine and Mass Airflow Sensor (MAF). By understanding how to interpret the results, technicians can identify potential breathing faults and take appropriate action to improve engine performance.

Changing Fuel Filter on Infiniti I30: Step-by-Step Guide

You may want to see also

The three methods of measurement

There are three methods of measurement used by different types of injection systems to determine appropriate fuelling: Speed Density, Mass Airflow, and Alpha-N. Each system uses different parameters to calculate fuelling, but the end goal is the same: maximise performance while minimising fuelling errors.

Speed Density

Speed Density measures the engine's speed and air density to help the tuner arrive at the proper calibration. It uses a Manifold Absolute Pressure (MAP) sensor, an Intake Air Temperature (IAT) sensor, and a monitor for engine RPM to calculate air density and, subsequently, fuelling. The MAP sensor provides instant feedback on engine manifold pressure, which, along with data from the IAT sensor, helps determine air density and required fuel adjustments. This method is often used by hardcore racers who have measurable data on their engine combination and can make educated decisions on changes.

Mass Airflow

Mass Airflow uses a mass air flow sensor (MAF) to measure the volume of air entering the engine. The sensor is located before the throttle body and can be one of several types, including hot-wire or frequency-based. It measures airflow passing over its surface and sends these values, along with data from the intake air temperature sensor, to the ECU. The ECU then calculates air density and required fuel adjustments. A potential downside of this method is that MAF is very particular about how and where the sensor is installed. Any changes to the sensor location can result in incorrect readings and messy calculations.

Alpha-N

Alpha-N is used on naturally aspirated engines and measures the throttle position sensor and RPM to arrive at its calculations. It works on the pounds-per-hour concept, referencing RPM versus the percentage of throttle opening. Alpha-N is typically used when there is a large camshaft that creates terrible or fluctuating vacuum, so the engine management system uses throttle angle to make fuelling adjustments. A disadvantage of this method is that it can't sense changes in load, for example, when shifting from Neutral to Drive. It also requires retuning if the throttle body is changed. Alpha-N is best used on drag race-only engines.

When to Replace Your Fuel Tank Vent Valve

You may want to see also

Frequently asked questions

The Base Fuel Table is the foundation of your fuel map, and it can be tuned over time using the Learn Table or manual adjustments. The Learn Table is a modifier of the Base Fuel Table and indicates how much the Base Fuel Table has been altered.

In the Learn Parameters menu, select "Base Fuel Learn Enabled". This will update the Base Fuel Table with the current Learn values, allowing you to blend the Fuel Graph for smooth transitions.

Manually blending the Fuel Graph is more effective than using the "Smooth" button option. Highlight segments of the Base Fuel Table, click "Graph", and blend the Fuel Graph to make it smooth.

When the Learn Table values stop making significant changes, the ECU is finished self-tuning. You can then transfer learning to the Base Fuel Table and blend the Fuel Graph.

Decrease the Learned Compensation Limits to around 2% in the idle area and 10% elsewhere. Also, decrease the Closed Loop Compensation Limits to 50% or less.