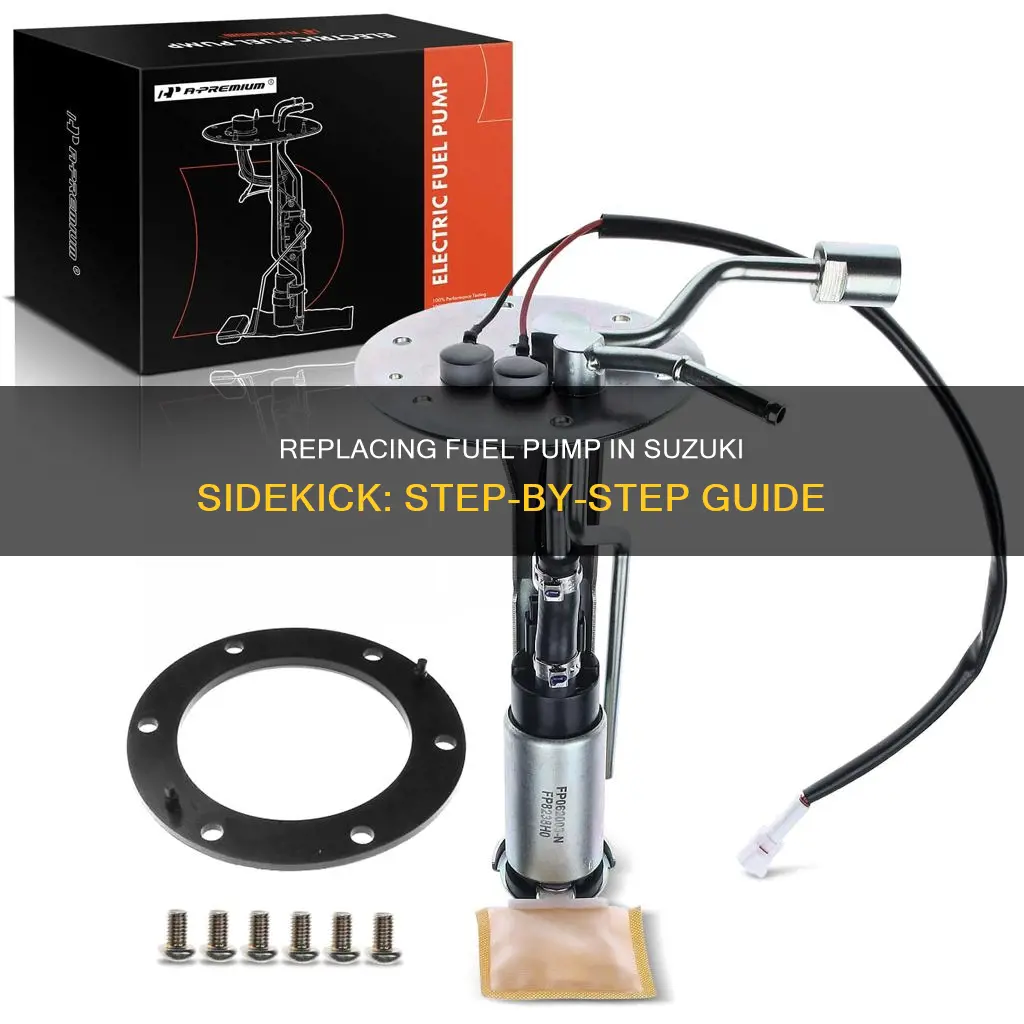

If you're looking to replace the fuel pump in your 1993 Suzuki Sidekick, you're in the right place. This job can be a little tricky, but with the right tools and some patience, you can definitely handle it. You'll need to remove the gas tank and pay close attention to the fuel pump's location and the surrounding components. It's also important to ensure that any access holes you create are properly sealed to prevent exhaust gases from entering the car.

What You'll Learn

- Check for power at the fuel pump

- Check for a bad connection in the connector behind the left rear taillight

- Check for power and ground to the pump when you cycle the key or crank the engine

- Consider cutting a hole in the floor for access

- Ensure any hole is sealed properly to keep exhaust gases out of the car

Check for power at the fuel pump

To check for power at the fuel pump of your 1993 Suzuki Sidekick, you should:

- Check for power at the fuel pump connector.

- Check the fuel pump relay for power and function at the ECM (around the driver's side kick panel).

- Check the fuel pump ground behind the left taillight.

- Test for power at the pump (a two-wire connection near/under the left side, rear bumper).

If the connection behind the left rear taillight is good and you have power and ground to the pump when you cycle the key or crank the engine, then replace the pump.

Suzuki Grand Vitara: Replacing Fuel Filter, Step-by-Step Guide

You may want to see also

Check for a bad connection in the connector behind the left rear taillight

To check for a bad connection in the connector behind the left rear taillight of your 1993 Suzuki Sidekick, you'll need to do the following:

Firstly, locate the connector behind the left rear taillight. This is where you'll find the fuel pump ground, which is known to sometimes cause issues.

Next, check for power at the fuel pump. If there is no power, the problem could be a bad connection in the connector. If there is power, but the car still won't start, you may need to replace the pump.

If you suspect a bad connection, you can use a test light to probe the connector for power. Ensure that your test light is working before beginning diagnostics. Connect the test light to the negative battery terminal, or any good body ground, and touch the probe end to the positive-side battery terminal. The test light should light up.

Now, turn on the light switch and ground the tester to a clean screw on the body of the car. Probe the contacts in the connector to see if the tester lights up. If the contacts are corroded, carefully scrape off the corrosion with a small screwdriver or wire brush. The tester should light up for two out of three contacts (one won't light up because it's a ground). If two light up, then the connector is likely not the issue, and you should move on to checking other potential causes.

If only one or none of the contacts show power, the problem may lie elsewhere in the wiring. Push the point of the tester through the wire insulation behind the connector to make contact with the wire. If the tester lights up for two of the three wires (the ground wire won't light up), then the wiring is likely not the issue, and you should consider replacing the connector. If the tester doesn't light up for two wires, there may be a problem with the wiring or another connector.

By following these steps, you can effectively check for a bad connection in the connector behind the left rear taillight of your 1993 Suzuki Sidekick and narrow down potential causes for any issues you may be experiencing.

Changing Nuclear Reactor Fuel: A Step-by-Step Guide

You may want to see also

Check for power and ground to the pump when you cycle the key or crank the engine

To check for power and ground to the fuel pump on a 93 Suzuki Sidekick when you cycle the key or crank the engine, follow these steps:

- Locate the fuel pump relay: The fuel pump relay is usually located in the engine compartment, often in a fuse box or relay panel. It may be labelled as such, or you can refer to your vehicle's service manual or an online forum for Suzuki Sidekicks.

- Check for power at the relay: With the key in the "on" position, use a test light or multimeter to check for power at the fuel pump relay. This will help determine if the relay is receiving power from the main relay and ignition.

- Check the wiring: Ensure that the wiring to the fuel pump is intact and connected properly. Look for any signs of damage, corrosion, or loose connections.

- Check for voltage at the fuel pump connector: With the key in the "on" position, use a test light or multimeter to check for voltage at the fuel pump connector. This will help confirm if power is reaching the fuel pump.

- Listen for the fuel pump priming: With the key in the "on" position, listen carefully for the fuel pump priming. It should run for about three seconds and then stop. If it doesn't prime, it may indicate an issue with the fuel pump relay or a problem with the wiring.

- Check the fuel pump ground: The fuel pump ground is typically located behind the left taillight. Ensure that this connection is clean and free of corrosion. A poor ground connection can affect the fuel pump's operation.

- Check fuses: Check the relevant fuses, such as the ig-coil fuse and the F1 fuse, to ensure they are not blown.

By following these steps, you can effectively check for power and ground to the fuel pump when you cycle the key or crank the engine on your 93 Suzuki Sidekick.

Replacing Fuel Injectors: 2006 Nissan Altima Guide

You may want to see also

Consider cutting a hole in the floor for access

If you're looking to replace the fuel pump on your 1993 Suzuki Sidekick, one option to consider is cutting a hole in the floor for access. This can be a more straightforward approach than removing the gas tank.

- Planning and Measurement: Before you start cutting, it's crucial to plan and measure carefully. Measure and mark the area above the fuel tank where you intend to cut the hole. This area is typically at the rear of the vehicle, above the tank.

- Drilling and Hole Creation: Begin by drilling a few small holes in the marked area. Use these holes to insert small nails or screws as reference points for your intended cut. This will help you visualise the hole's position and size.

- Structural Considerations: Be mindful of the body structure of your Suzuki Sidekick. There is typically a 3-inch by 3-inch body structure going from side to side across the back, with the floor welded to it. It is recommended to cut only the floorboards and not this structural component.

- Cutting the Hole: Using the reference points you've created, carefully cut the hole in the floor. Ensure you have the right tools for the job, such as a suitable saw or cutting tool.

- Accessing the Fuel Pump: With the hole cut, you should now have better access to the fuel pump. Reach through the hole to remove the old fuel pump and install the new one.

- Sealing and Covering the Hole: Once you've successfully replaced the fuel pump, it's essential to seal and cover the hole you created. Make sure to use appropriate materials to seal the hole properly, preventing exhaust gases from entering the vehicle.

Remember to take your time and work carefully. Cutting a hole in the floor for access to the fuel pump can be a practical approach, but it requires precision and attention to detail.

Always refer to your vehicle's service manual for specific instructions and safety precautions. Additionally, consider seeking advice from experienced mechanics or professionals before attempting any significant vehicle repairs.

Replacing Fuel Filter in Mazda Protege: Step-by-Step Guide

You may want to see also

Ensure any hole is sealed properly to keep exhaust gases out of the car

When working on your 1993 Suzuki Sidekick, it is important to take extra care to ensure that any holes made during the process of changing the fuel pump are properly sealed to prevent exhaust gases from entering the vehicle's cabin. Exhaust gases contain harmful pollutants, including carbon monoxide, which can be deadly if inhaled in high concentrations. Here are some detailed steps to ensure proper sealing:

Locate all holes: Before beginning the sealing process, identify all the holes that were made. This includes any drill holes, screw holes, or openings made during the repair work. Even a small hole can provide an entry point for exhaust gases, so it is important to account for each one.

Clean the area: Using a clean cloth or brush, remove any debris, dirt, or grease around the holes. A clean surface will ensure that the sealant adheres properly, creating an airtight seal.

Choose the right sealant: Select a high-temperature sealant designed specifically for automotive use. This sealant should be able to withstand high temperatures and resist shrinking, cracking, or peeling over time. Read the instructions on the sealant carefully to ensure it is suitable for the task.

Apply the sealant: Follow the instructions on the sealant product. Typically, you will need to apply a generous amount of sealant around the perimeter of each hole. Use a caulking gun for precision and ensure that the sealant fills any gaps or crevices completely.

Smooth and wipe away excess: Use a clean finger or a small tool to smooth out the sealant, ensuring it fills all gaps evenly. Remove any excess sealant immediately before it dries, as it can be difficult to remove once cured.

Allow adequate curing time: Refer to the sealant's instructions for the recommended curing time. Do not rush this process, as proper curing is essential for a strong and durable seal.

By following these steps and taking your time to properly seal any holes, you can rest assured that exhaust gases will remain outside of your vehicle, keeping you and your passengers safe from harmful pollutants. Always remember to work in a well-ventilated area when dealing with sealants and adhesives, and wear appropriate protective gear, including gloves and eye protection.

Replacing the Fuel Relay Switch in a 1999 Jeep

You may want to see also

Frequently asked questions

You can access the fuel pump by removing the gas tank. Alternatively, you can cut a hole in the floor above the tank. However, this method requires proper sealing to prevent exhaust gases from entering the car.

You will need a 14 mm socket or wrench, a socket extender, and a 14mm and 15mm wrench.

First, lower the gas tank. Disconnect the hoses, electrical connectors, and fuel filter. Unscrew the pump using a Phillips screwdriver. Install the new pump and secure it with the screws. Reattach the hoses, electrical connectors, and fuel filter.

Yes, it is recommended to replace the fuel filter during this process. Additionally, ensure that all connections are properly sealed to prevent fuel leaks.