If your 1993 Mustang is hard to start or won't start at all, you may need to replace the fuel pump. The fuel pump is what pushes fuel from the tank and pressurizes it as it is delivered to the engine. To replace the fuel pump, you will need a replacement fuel pump, a fuel filter (optional but recommended), a gasket sealer, a sharp scraper, degreaser, sockets, a fuel cut-off clamp, a fuel line, clips, rags, and a drip tray. The first step is to stop the flow of fuel from the fuel tank. Then, remove the connection to the fuel pump. Next, remove the output side of the fuel pump, followed by the fuel pump body. Finally, install the new fuel pump and reconnect the fuel lines.

What You'll Learn

Disconnecting the fuel tank

Stop the Fuel Flow

First, you need to stop the flow of fuel from the fuel tank. This is a crucial safety step to prevent any accidental spills or leaks. Locate the fuel pump and identify the fuel pipe. Then, use a clamp to securely block the fuel pipe. A simple screw clamp will do the trick by squashing the rubber pipe and preventing any fuel flow.

Place a Drip Tray

As a precautionary measure, place a drip tray or a receptacle beneath the fuel tank to catch any fuel that may drip or leak during the disconnection process. This will help contain any spills and make cleanup easier.

Disconnect the Fuel Pump Connections

Depending on your Mustang's setup, you will need to remove the connections to the fuel pump. There may be different types of clips or clamps holding the rubber pipes in place, such as crushed (lemon) style clips or jubilee clips. Carefully cut or disconnect the rubber pipes to avoid any damage to the filter or other components.

Undo the Fuel Filter Connections

If your Mustang has a fuel filter, you will need to disconnect it as well. Cut or disconnect the rubber pipes on both sides of the fuel filter. Be prepared to catch any remaining fuel that may run out of the pipes.

Remove the Metal Pipe to the Carburettor

The output side of the fuel pump is connected to a metal pipe that leads to the carburettor. Loosen and unscrew the nut holding this metal pipe in place. Again, be ready to catch any residual fuel that may run out.

Disconnect the Fuel Tank Connections

In addition to the fuel pump connections, there are a few other connections to the fuel tank that need to be addressed. These include the fuel filter, the evaporator (evap) in and out, a tube on the front driver's side, and the filler. Disconnect all of these carefully, ensuring that you don't damage any components or cause fuel leaks.

Lower the Fuel Tank

To gain better access to the fuel pump and its connections, you may need to lower the fuel tank partially. This can be done by removing the bolts that hold the filler to the body on the outside of the car and the boot that goes through the trunk floor. Tilt the driver's side of the tank down and pull it towards the driver's side while simultaneously pulling the tank filler towards the passenger side. This step may require some strength, and having an extra pair of hands to help can be beneficial.

By following these steps, you will have successfully disconnected the fuel tank and can now focus on removing and replacing the fuel pump. Remember to work with caution and always be mindful of any fuel leaks or drips during the process.

Fuel Prices: Fluctuating Fortunes and the Factors Behind Them

You may want to see also

Removing the fuel pump

The first step is to stop the flow of fuel from the fuel tank. As a precaution, you can clamp the fuel pipe to prevent drips or residual fuel leaks. Use a simple screw-up clamp to squash the rubber pipe. Place a drip tray underneath to catch any fuel.

Next, you need to remove the connection to the fuel pump. There may be different types of clips or clamps holding the rubber pipe in place, so be prepared to cut the pipe if necessary. Once the pipe is disconnected, there may still be fuel inside, so be prepared for this to run out.

On the output side of the fuel pump, there should be a metal pipe leading to the carburettor. This is held in place by a nut and will also need to be unscrewed.

The fuel pump body is held in place by two bolts. You can remove these bolts in whichever order you prefer, depending on your setup and access to the pump.

There are a couple of ways to remove the pump. One method is to break both bolts free and undo them halfway so you can move the pump and determine the location of the fuel pump cam. Then, you can fully remove the bolts and take the pump out.

Alternatively, you can simply unbolt the pump and refit a new one. However, this may be more difficult as you will need to align the pump while inserting the bolt.

Once the pump is removed, clean the engine block surface to ensure a good seal for the new gasket. Use a razor blade scraper, working away from the opening and from the centre outwards.

You can now apply a thin bead of gasket sealer to one side of the new gasket (optional). Clean the pump face with a degreaser and lint-free cloth, then apply another thin film of gasket sealer (also optional).

Refitting the New Fuel Pump

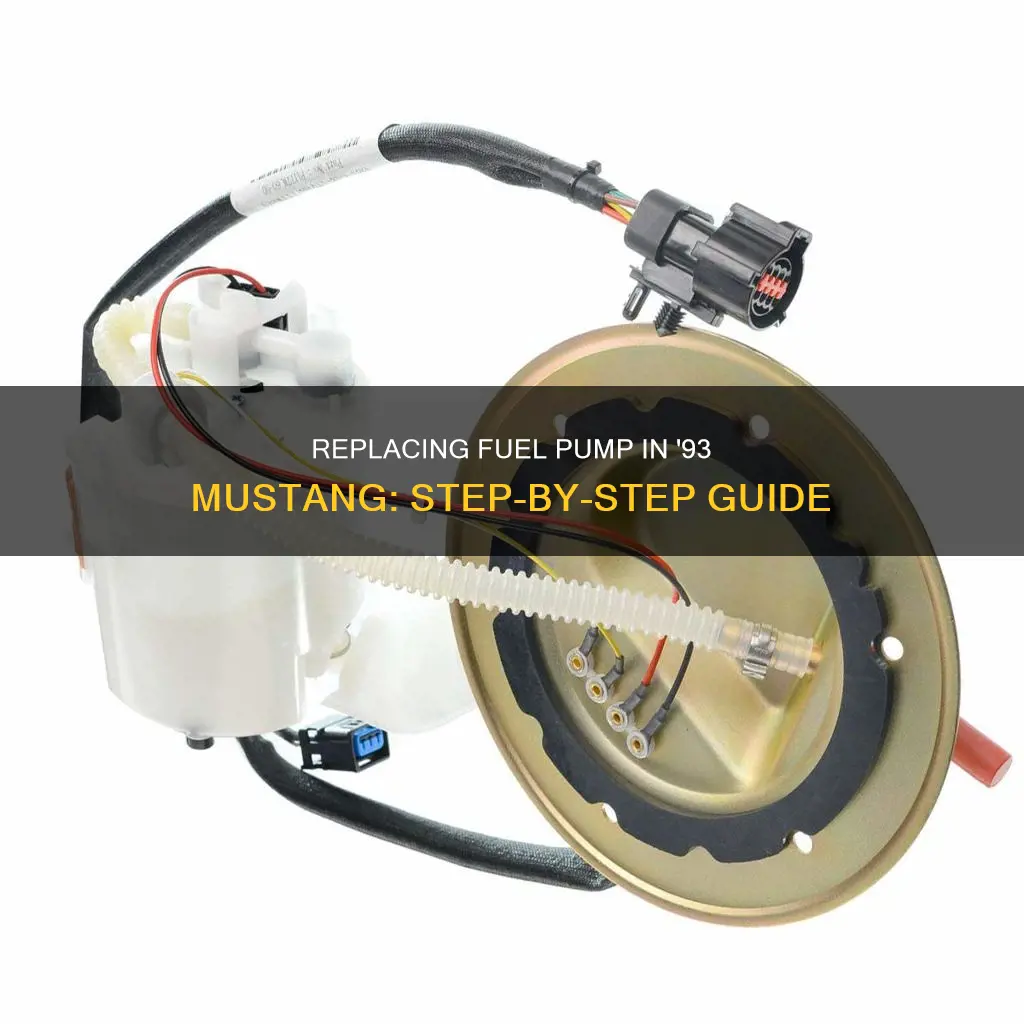

Refitting the new fuel pump requires a specific technique due to the cam on the arm of the pump. When inserting the pump arm into the engine block opening, tip the arm downwards at a slight angle. Then, tilt the pump face back towards the parallel of the engine block pump face to ensure the arm is under the cam before bolting it into place.

Start by getting the first bolt into the pump to hold it in place, choosing whichever side is easiest for you. Then, add the other bolt to mount the pump in the correct vertical position. Tighten the bolts evenly on both sides to form a tight seal.

Reattach the metal carb pipe to the output of the new pump and tighten it into place. Depending on the design of your pump, you may need to hold the mounting point nut with a spanner to avoid breaking the spot weld.

Now, attach the input line of the fuel pipe to the male part of the fuel filter, ensuring the flow direction arrow is pointing towards the fuel pump. Use a 'lemon' clip or a single-ear clip to make it neater, or a jubilee clip if you prefer.

Make sure the rubber fuel pipe is not kinked and forms as straight a route as possible to the fuel pump. Secure it in place with a clip or jubilee clip.

You can now fill the filter with fuel, or leave it empty to see if the pump pulls fuel into it when cranking over without starting the engine.

Reconnect the fuel line coming from the inner fender and remove the clamp previously put in place to stop fuel seepage. Recheck that all bolts and clips are secure, then crank the engine to ensure everything is correct before trying to start the car.

Changing Freightliner Fuel Water Separator Filters: Step-by-Step Guide

You may want to see also

Cleaning the engine block

To clean the engine block of your 1993 Mustang, you will need to first gather the necessary tools and materials. These include a degreaser, such as Greased Lightning, rags, plastic bags, brushes, a hose, and possibly a car wash.

If the engine block is still in the vehicle, start by plugging the obvious holes, such as the air breather and oil breather, and cover sensitive components like the distributor and coil with plastic bags. Next, spray the engine block with a degreaser and let it sit for a while to break down the grease and grime. If the engine is extremely greasy, you may need to use a brush to scrub away some of the buildup. Once the degreaser has had time to work, use a hose to rinse off the engine block, being careful not to get water into sensitive areas. If the vehicle is drivable, you can perform this step at a car wash.

If the engine block is on the ground or easily accessible, you may want to consider dismantling it and having the block hot tanked, which involves a process of chemical cleaning using hot temperatures and immersion. This option may be more suitable if the engine block is heavily soiled or if you are planning to rebuild the engine.

It is important to note that you should avoid using high-pressure water or spraying a hot engine with cold water, as this can cause damage to the engine block and its components. Always exercise caution when cleaning an engine block and refer to the owner's manual for specific instructions and safety precautions.

Additionally, when cleaning the engine bay, you can use a diluted all-purpose cleaner, such as Simple Green, and a low-pressure garden sprayer or a compressor-powered engine cleaning gun to rinse. Cover any water-sensitive parts with aluminum foil or plastic wrap to protect them from moisture. Alternatively, you can use rags dampened with cleaner to wipe down the engine bay, being careful to avoid getting wiring and electrical components wet.

Tire Size Impact: Fuel Efficiency Secrets Revealed

You may want to see also

Installing the new fuel pump

To install the new fuel pump, you will need a replacement fuel pump, a fuel filter (optional but recommended), a gasket sealer, a sharp scraper, degreaser, sockets, a fuel cut-off clamp, a fuel line, clips, rags, and a drip tray.

First, you need to clamp the fuel off. Place a drip tray or receptacle to catch any dripping fuel. Remove the connection to the fuel pump, which may involve cutting the rubber pipe. Next, remove the metal pipe on the output side of the fuel pump, which goes up to the carburettor, using a wrench to unscrew the nut. Then, remove the bolts holding the fuel pump in place and take the pump out.

Now, clean the engine block surface with a razor blade scraper, working away from the opening and from the centre outwards. Degrease the surface with a lint-free cloth. Apply a thin bead of gasket sealer to one side of the new gasket. You can also apply a thin film of gasket sealer to the pump face after cleaning it with degreaser.

To refit the new pump, insert the pump arm into the engine block opening, tipping the arm downwards at a slight angle. When the pump is almost at the engine block, tilt the pump face back towards the parallel of the block. This ensures the arm is under the cam before bolting into place. Get the first bolt in the pump to hold it in place, then add the other bolt to mount the pump in the correct vertical position. Tighten the bolts evenly to form a tight seal.

Finally, reattach the metal carb pipe to the output of the new pump and tighten it into the mounting. Attach the input line of the fuel pipe to the male part of the fuel filter, ensuring the flow direction arrow is pointing to the fuel pump. Fill the filter with fuel if desired. Reconnect the fuel line from the inner fender and re-check that all bolts and clips are secure. Crank the engine to ensure everything is correct before trying to start the car.

Changing Fuel Filter on Passat: Step-by-Step Guide

You may want to see also

Reattaching the fuel tank

To reattach the fuel tank, you will need to reconnect the filler pipe and the various tubes and electrical connectors.

First, ensure that the rubber grommet is in place on the filler pipe. Soak the grommet in hot water to soften it, and lubricate the end of the filler pipe with motor oil. Then, reconnect the filler pipe to the fuel tank. This may require some strength, as the pipe fits very tightly.

Next, reconnect the five tubes and electrical connectors to the tank. These include the fuel filter, evap in/out, another tube on the front driver side, the filler, and one electrical connector.

Finally, ensure that the float is working before reinstalling the access plate.

Fuel Filter Maintenance for Toyota T100: How Often?

You may want to see also

Frequently asked questions

If your Mustang is very hard to start or won't start at all, turn the key in the ignition and listen near the gas tank. If you don't hear any noise or you hear a loud whine, the fuel pump may be failing.

The fuel pump relay is located in the Integrater Relay Control Module, which can be found on the right strut tower.

You will need a replacement fuel pump, a fuel filter (optional but recommended), a gasket sealer, a sharp scraper, degreaser, sockets, a fuel cut-off clamp, a fuel line, clips, rags, and a drip tray.

First, clamp the fuel line to stop the flow of fuel from the fuel tank. Then, remove the connection to the fuel pump and place a drip tray underneath to catch any fuel that leaks out. Next, remove the output side of the fuel pump, followed by the bolts holding the fuel pump in place. Finally, install the new fuel pump and reconnect the fuel lines.