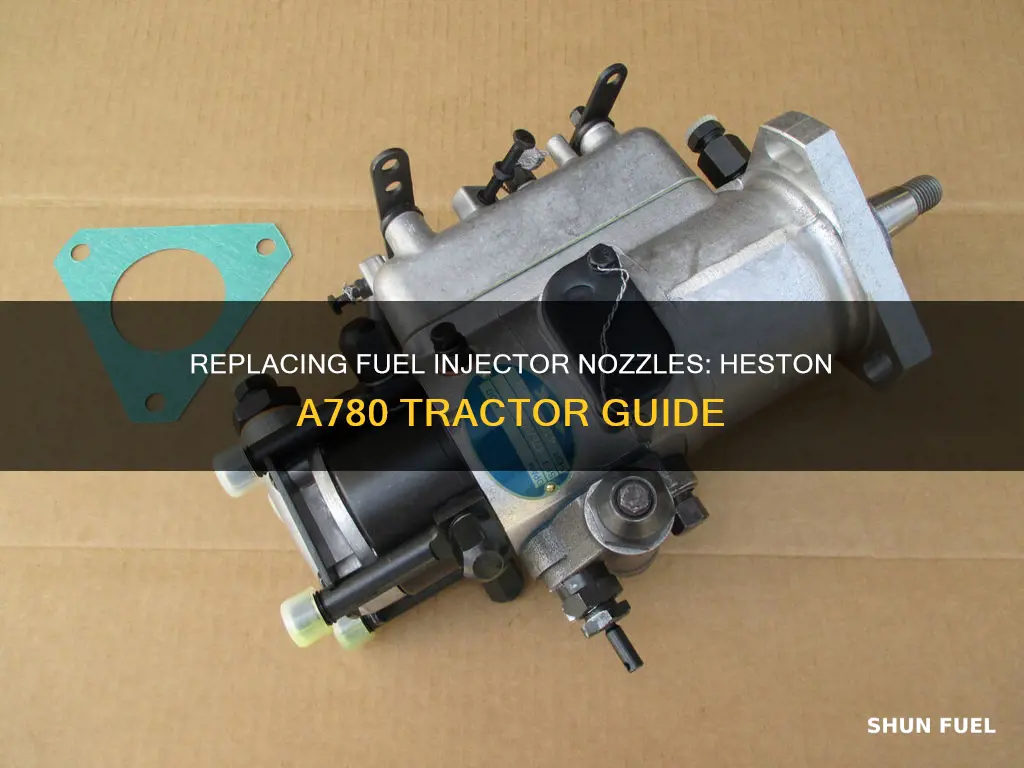

The fuel injector nozzle is a critical component of a diesel engine's performance and emissions. It is responsible for delivering atomized fuel into the engine's combustion chamber for efficient combustion and power generation. The process of changing fuel injector nozzles can be complex and requires careful handling of the equipment. It is important to wear gloves and safety glasses to protect oneself from potential high-pressure diesel injections. The steps involved in changing fuel injector nozzles include inspecting the nozzle for any signs of clogging, damage, or wear, conducting a fuel pressure test, cleaning or replacing the nozzle if necessary, and ensuring proper sealing and alignment during reassembly.

What You'll Learn

Safety precautions

Before attempting to change the fuel injector nozzles on your A780 Heston diesel tractor, it is important to take several safety precautions to ensure your protection and the proper handling of the equipment. Here are the steps you should follow:

- Use Personal Protective Equipment (PPE): Wear gloves and safety glasses to protect your hands and eyes from any potential hazards. Diesel injectors operate at extremely high pressures, and if handled carelessly, they can inject diesel into your skin or eyes, leading to serious injuries.

- Clear the Work Area: Ensure that the testing or repair area is free from any potential hazards or obstacles. Keep the injector nozzles away from children, pets, or bystanders to avoid accidental injury.

- Disconnect the Battery: Before working on any part of the tractor's engine, it is crucial to disconnect the battery to prevent accidental electrical hazards or short circuits.

- Relieve Fuel System Pressure: Before removing or working on the fuel injector nozzles, make sure to relieve the pressure in the fuel system. This can be done by shutting off the fuel supply and allowing the engine to run until it stops due to fuel starvation. This step is crucial to prevent fuel spray or leakage during the repair process.

- Proper Handling of Components: When handling the injector nozzles and their components, be cautious and avoid using excessive force. Some parts, such as the locknut, protection cap, and nozzle nut, may be very tight. Use appropriate tools like a 6-sided socket and a long bar to loosen them gently.

- Cleanliness: Maintain a clean work environment and ensure that all components are free from dirt, debris, and contaminants. Use a degreaser, wire brush, or ultrasonic bath with carburettor cleaner to clean the injector nozzles and their parts. This will help prevent clogging and ensure optimal performance.

- Fuel Handling: Exercise extreme caution when handling diesel fuel. It is highly flammable, so avoid any open flames or sparks during the repair process. Have proper ventilation in your work area to prevent the buildup of fuel vapors.

- Label and Organize: When disassembling the injector nozzles, keep the components organized and labelled. Some parts, such as the nozzle and valve, are matched pairs and should not be mixed with those from other injectors. Store them in fuel or light oil if they are not going to be reassembled immediately.

- Avoid Damage: Be especially careful when handling the valve, as it is critical to the reliable operation of the injector nozzle. Even the acid from human hands can cause damage, so it is recommended to wear lightweight medical gloves during the process.

- Professional Guidance: If you are unsure about any aspect of the repair process, seek professional guidance or advice from a qualified mechanic. Some tasks, such as testing and adjusting the injectors, may require specialized equipment and knowledge.

By following these safety precautions, you can help ensure that the process of changing the fuel injector nozzles on your A780 Heston diesel tractor is safe, efficient, and successful.

Replacing Fuel Filter in 2007 Dodge Fakota: Step-by-Step Guide

You may want to see also

Common problems with injectors

Fuel injectors are a critical component of your tractor's engine, spraying a fine mist of diesel fuel into the combustion chamber, where it mixes with air and ignites to power the tractor. Over time, fuel injectors can experience problems that can affect the performance and operation of your tractor. Here are some common issues you may encounter:

Clogs and Carbon Build-up

Fuel injectors can become clogged with carbon deposits and debris over time. This build-up can restrict the flow of fuel, leading to poor engine performance, increased fuel consumption, rough idling, and even engine misfires. It is recommended to have your injectors professionally cleaned every 60,000 to 90,000 miles to prevent and address clogging issues.

Leaks

Leaking fuel injectors are a rare but serious problem. Leaks are typically caused by o-ring failure or cracks in the injector itself. Engine heat can cause o-rings to become brittle and crack, leading to fuel leaks. Leaking fuel can not only reduce engine performance but also poses a safety hazard. If you notice any signs of fuel leaks, such as wetness around the fuel injectors or the smell of gasoline, it is important to address the issue immediately.

Engine Misfires and Vibrations

Dirty or malfunctioning fuel injectors can cause the engine to misfire, resulting in vibrations throughout the tractor. You may feel a rhythmic shaking or a hiccupping sensation while driving, especially when maintaining a steady speed. Engine misfires are often accompanied by a hesitation or stumble when accelerating, as if the engine is briefly losing power.

Rough Idling

Clogged or faulty fuel injectors can lead to rough idling, where the engine RPM varies even when your foot is off the gas pedal. Rough idling may also be accompanied by engine stalling, where the engine suddenly stops running. In some cases, rough idling can be a sign of other engine problems, so it is important to have your tractor properly diagnosed.

Poor Fuel Economy

A bad fuel injector may deliver too much or too little fuel to the engine, affecting your tractor's fuel efficiency. You may find yourself filling up your fuel tank more often than usual. Additionally, the engine control unit (ECU) may compensate for perceived fuel shortages by injecting even more fuel, further worsening the problem.

Check Engine Light

The "Check Engine" light on your dashboard can indicate a variety of issues, including problems with your fuel injectors. If the light illuminates, it is important to use an OBD2 scanner to diagnose the specific issue and determine if the fuel injectors need attention.

When to Change Your F250 Diesel Fuel Filter

You may want to see also

Symptoms of faulty injectors

The fuel injection system is critical to the performance of your diesel engine. It is responsible for pressurising and injecting fuel into the combustion chamber. If your tractor is exhibiting any of the following symptoms, it may be a sign of faulty injectors:

- Trouble starting the engine or uneven idling: The engine cranks but doesn’t start unless cranked for a long time. The engine may also use different speeds of revs on idle.

- Misfiring: A misfire could be due to a lack of fuel injection or a lack of combustion chamber heat. There may be a low level of fuel being pumped into the ignition, or the fuel in one of the cylinders fails to ignite.

- Smell of diesel: The smell of diesel inside the cabin indicates a leak somewhere. This could be from a faulty injector leaking fuel when it isn’t active.

- Dirty emissions: Clogged filters and injector deposits cause an uneven or incomplete fuel burn. This results in a dirty area around the exhaust and white smoke from the exhaust pipe.

- Increased fuel consumption and poor miles per gallon: Faulty injectors burn more fuel, impacting the vehicle’s performance and efficiency.

- Engine does not reach full RPM

- Rough engine performance

- Surging and bucking under various throttle loads

- Smoke from the tailpipe

- Engine knock or detonation, which can lead to catastrophic engine failure

If your tractor is exhibiting any of these symptoms, it is recommended to have a trusted professional inspect and diagnose the issue.

Changing the Fuel Filter in a Polaris 800 (2006 Model)

You may want to see also

Step-by-step guide to testing injectors

Testing your fuel injectors is a practical skill that can save you money and keep your vehicle running efficiently. Here is a step-by-step guide to testing your fuel injectors:

Step 1: Visual Inspection

- Ensure the engine is off and cooled down before starting any inspection.

- Inspect for fuel leaks around the injectors. Leaks may indicate a sealing issue or a cracked injector.

- Check for corrosion and dirt. Clean the injectors and surrounding areas. Dirt and corrosion can affect performance.

- Look for cracks or physical damage. If found, the injector needs to be replaced immediately.

Step 2: Fuel Pressure Testing

- Locate the fuel rail where the injectors are joined.

- Attach a fuel pressure gauge to the fuel rail's test port.

- Turn on the engine and let it run.

- Compare the gauge reading to your vehicle's manual specifications.

- Diagnose issues: Low pressure could be caused by a faulty fuel pump, clogged fuel filter, or injectors.

Step 3: Injector Balance Test

- Prepare an injector tester by following the manufacturer's instructions.

- Connect the tester to the first injector.

- Activate the tester to simulate fuel delivery for a set period.

- Measure and collect the amount of fuel delivered.

- Repeat the process for each injector and compare the outputs. Identical outputs indicate good injectors. Significant differences suggest one or more injectors are faulty.

Step 4: Ohm Test with a Multimeter

- Disconnect the injector's electrical connector.

- Set the multimeter to the ohms setting.

- Measure resistance by placing the probes on the injector terminals.

- Compare your reading to the manufacturer's specifications. An out-of-range reading indicates a problem.

Step 5: Injector Spray Test

- Carefully remove the injectors from the engine, keeping them attached to the fuel rail.

- Position the injectors in a clear area where you can observe the spray pattern.

- Have someone crank the engine while you observe the spray.

- Look for a fine, even spray. Irregular patterns indicate clogs or damage.

- If the spray pattern is poor, try cleaning the injectors. If the issue persists, replace the faulty injectors.

Tips for Effective Testing:

- Clean injectors regularly to prevent clogging and improve performance.

- Use high-quality fuel to reduce deposits and prolong injector life.

- Regular vehicle maintenance helps identify and fix issues early.

Changing the Fuel Filter in Your Turbo Beetle

You may want to see also

Cleaning and repairing injectors

Using a Fuel Injection Cleaning Kit

If your engine is stuttering or producing dark clouds of smoke, your injectors may be clogged. A fuel injection cleaning kit is a cheap and easy way to clear stubborn residue from your injectors.

First, ensure your engine is off and remove the keys from the ignition to prevent the battery from sending power to the engine. Then, open the cap that covers the fuel tank. Next, disconnect the fuel pump by locating the fuse box under the hood, opening it, and removing the fuel pump fuse. Try to start the engine to make sure the fuel pump is disconnected. You should hear the "click" of the starter.

Now, connect the output hose of the fuel rail to the cleaning kit. Check the instructions on the kit to ensure the correct air pressure is flowing into the kit and adjust the flow if necessary. Then, start the engine and let it run for 15 minutes to use up the solvent. Once the engine stops, turn off the battery, disconnect the kit, and reconnect the fuel pump. Start the engine and listen for any strange noises. If you notice anything unusual, take your vehicle to a mechanic.

Using Diesel Fuel Additives

If your injectors are only mildly clogged, you can simply add a diesel fuel additive to your tank. Before doing so, ensure the engine is off and the fuel tank is almost empty. Locate and open the vehicle's fuel tank and pour in the recommended amount of additive. Then, fill the tank with diesel and run the engine for 10 minutes to circulate the additive throughout the fuel system.

Removing and Flushing Injectors

You can also try removing and flushing your injectors. This can be done by a professional mechanic, or you can do it yourself if you have some mechanical skill. First, remove the injectors, then disassemble and clean them in an acetone bath using wire brushes. Be careful during this process, as it is easy to damage the parts and tips of the injectors. You must also know how to put them back together correctly.

Best Practices for Injector Maintenance

- Use high-quality fuel with the appropriate cetane rating for your engine.

- Change your fuel filters at the recommended intervals to prevent contaminants from reaching the injectors.

- Maintain proper fuel pressure as per your engine's specifications.

- Use the right engine oil with the correct viscosity rating and change it as recommended.

When to Change Your Prius V's Fuel Filter

You may want to see also