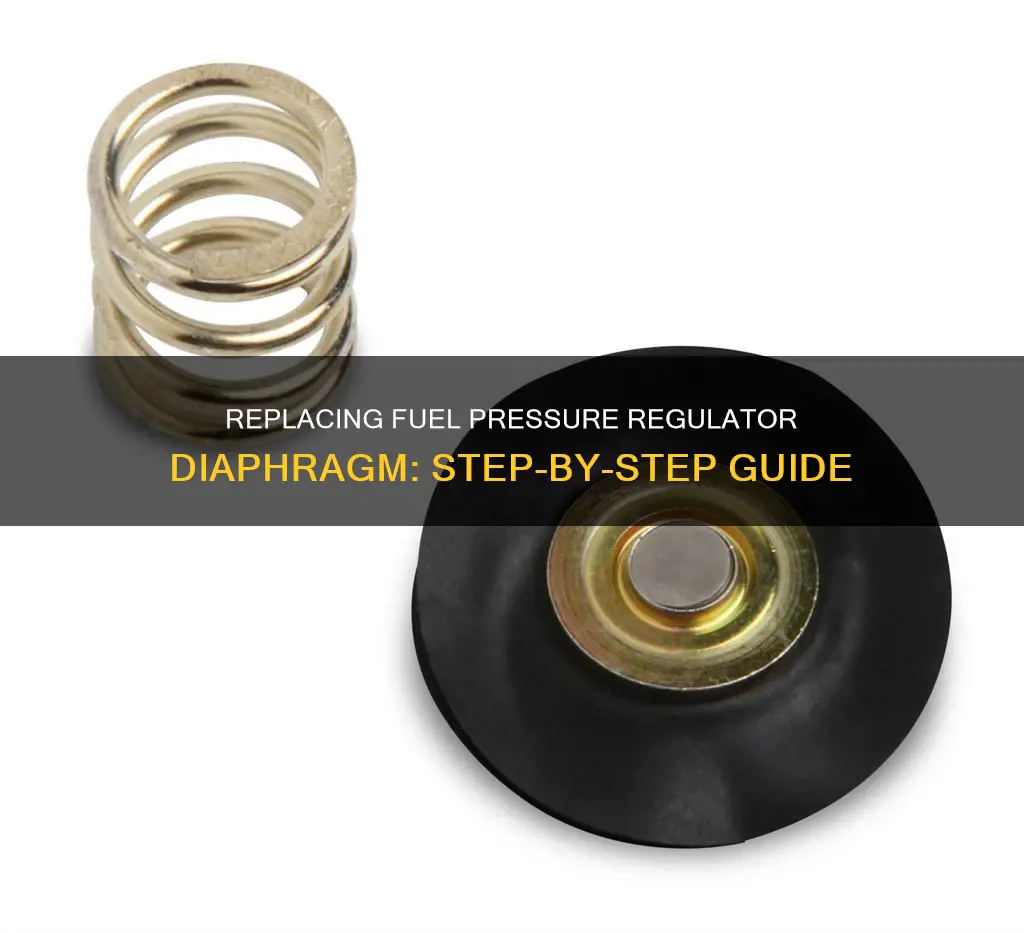

A fuel pressure regulator is an important part of a car's fuel delivery system. It controls the amount of fuel pressure to each injector, ensuring the engine gets the right amount of fuel and maintaining constant fuel pressure for optimal fuel usage. The regulator contains a spring that presses against a diaphragm, which can wear out over time. Replacing the diaphragm in a fuel pressure regulator can be done at home with a few common tools, saving over $200 in repair costs. This involves relieving the system's pressure, removing the relevant hoses and vacuum lines, taking out the old diaphragm, and putting a new one in its place.

What You'll Learn

Disconnect the battery

Disconnecting the battery is an important step when changing a fuel pressure regulator diaphragm. This is because the battery powers the fuel pump, and disconnecting it will disable the power going to the pump.

To disconnect the battery, first, open the vehicle's hood. Then, put on protective gloves to protect your hands. Next, following the vehicle owner's manual, remove the ground cable from the battery's negative post. This will ensure that the power to the fuel pump is disabled.

It is important to note that attempting to crank the starter more than five times without a functioning fuel pressure regulator can lower the battery's performance. Therefore, it is advisable to not attempt to crank the starter more than five times if the engine does not start.

Additionally, if you do not have a nine-volt battery saver, you can skip this step. However, if you do have one, it is recommended to install it into your cigarette lighter before disconnecting the battery. This will keep your computer live and your settings current in the vehicle.

Once you have finished replacing the fuel pressure regulator diaphragm, you can reconnect the battery by reattaching the ground cable to the battery's negative post and tightening the battery clamp to ensure a good connection.

Fuel Pump Functionality: Tank Hoses Off, Pressure On?

You may want to see also

Remove the engine cover

Removing the engine cover is a simple task that can be completed by following these steps:

Firstly, it is important to note that the engine cover is typically secured by a few screws. Using the appropriate screwdriver, carefully remove these screws and set them aside in a safe place. This will allow you to access the engine and begin the process of replacing the fuel pressure regulator diaphragm.

Some vehicles may have additional brackets or components attached to the engine cover. If this is the case, take note of the order and orientation of these parts to ensure proper reassembly. Carefully remove any brackets or components that may obstruct your access to the fuel pressure regulator. It is important to be gentle during this process to avoid damaging any surrounding components or wiring.

Once all the screws and relevant brackets have been removed, you can carefully lift and remove the engine cover. Set it aside in a safe place, keeping in mind that you will need to reinstall it once the fuel pressure regulator diaphragm replacement is complete.

With the engine cover removed, you should now have clear access to the fuel pressure regulator and the necessary space to work on it. Proceed with the replacement process as outlined in the previous response, ensuring that you follow all safety precautions and refer to vehicle-specific instructions or manuals if needed.

Remember to keep the engine cover in a designated area so that you can easily locate it when it's time to reinstall it. Reinstalling the engine cover will be the final step of the fuel pressure regulator diaphragm replacement process, and you can refer to these steps in reverse to securely put it back in place.

Fuel Pump Relay: Can It Cause Low Fuel Pressure?

You may want to see also

Check for leaks

Once you have finished replacing the fuel pressure regulator, it is important to check for leaks. Here is a step-by-step guide on how to do this:

Step 1: Reconnect the battery

Open the vehicle's hood and reconnect the ground cable to the battery's negative post. Ensure that the connection is good by tightening the battery clamp.

Step 2: Remove the wheel chocks

Remove the wheel chocks from the rear wheels and set them aside.

Step 3: Turn the ignition key on

Turn the ignition key on and listen for the fuel pump to activate. Then, turn off the ignition after the fuel pump stops making noise. You will need to cycle the ignition key on and off 3 to 4 times to ensure the fuel rail is full of fuel and pressurized.

Step 4: Check for leaks

Use a combustible gas detector to check all the connections for any leaks. Also, sniff the air for any fuel odours.

Step 5: Test drive the vehicle

During the test drive, listen for any engine cylinders not firing correctly and feel for any odd vibrations.

Step 6: Check for dashboard warning lights

Monitor the dashboard for the fuel level and for any engine light to appear. If the engine light comes on, even after replacing the fuel pressure regulator, further diagnosis of the fuel system may be required. This issue may be due to a possible electrical issue within the fuel system.

Setting Fuel Pressure: Suntec Oil Pump Guide

You may want to see also

Test drive the vehicle

Once you've replaced the fuel pressure regulator, it's time to test drive the vehicle to ensure that everything is functioning as it should. Here are some detailed steps and things to look out for during the test drive:

- Start the engine and let it idle for a while before taking the vehicle for a drive. Listen carefully for any unusual noises, such as cylinders not firing correctly or unusual vibrations. A misfiring engine is a common symptom of a faulty fuel pressure regulator.

- Pay close attention to the dashboard warning lights during the test drive. Monitor the fuel level and keep an eye out for any engine warning lights. If the check engine light comes on, it could indicate an issue with the fuel system, and further diagnosis may be required.

- Take the vehicle for a drive around the block or on a route that includes a variety of driving conditions, such as different speeds and terrain. Listen for any unusual engine noises and feel for any odd vibrations or changes in the vehicle's performance. A faulty fuel pressure regulator can cause issues such as decreased engine performance, loss of acceleration, and hard starting.

- Be mindful of any fuel odours during the test drive. A fuel leak is a symptom of a faulty fuel pressure regulator, and you may notice a strong fuel smell if there is a leak.

- If possible, compare the vehicle's performance to that before the fuel pressure regulator was replaced. Notice any improvements or changes in how the vehicle drives, accelerates, and idles.

- If you notice any issues or unusual behaviour during the test drive, it is important to consult a certified technician or mechanic. They can inspect the fuel pressure regulator, diagnose the problem, and recommend any necessary repairs or adjustments.

Remember to follow all safety precautions and adhere to local traffic regulations during the test drive. It is also a good idea to have a basic tool kit and safety equipment in the vehicle in case of any unexpected issues.

Plug Fuel Pressure Regulator: DIY Guide

You may want to see also

Prepare the necessary tools and materials

To prepare for changing a fuel pressure regulator diaphragm, you will need to gather the necessary tools and materials. This process requires a range of equipment, from safety gear to automotive tools, so it is important to be thorough in your preparation. Here is a detailed list of the items you will need:

- Safety Gear: Before you begin, ensure you have the appropriate safety gear to protect yourself. This includes fuel-resistant gloves to shield your hands from any harmful chemicals and protective eyewear to guard your eyes from debris and sparks. It is also recommended to wear other protective clothing, such as a long-sleeved shirt and pants, to avoid any potential skin exposure to fuel or sharp components.

- Combustible Gas Detector: This device is essential for identifying any fuel leaks in the system. It will help you detect even the smallest traces of combustible gases, ensuring your safety and allowing you to pinpoint the source of any leaks.

- Fuel Hose Quick Disconnect Kit: A fuel hose quick disconnect kit will come in handy when you need to separate fuel lines or hoses quickly and efficiently. It is specifically designed for this purpose and can save you time and effort during the replacement process.

- Ratchet with Metric and Standard Sockets: You will need a ratchet with both metric and standard sockets to tighten or loosen bolts of various sizes. The ratchet provides the necessary mechanical advantage to apply torque and secure or remove fasteners.

- Small Flat-Tip Screwdriver: A small flat-tip screwdriver will be useful for various tasks, such as opening the Schrader valve on the fuel rail and other precision tasks involving small screws.

- Other Tools: Depending on your vehicle's make and model, you may also require additional tools. These could include an OBD2 scanner to check for error codes, a manual vacuum pump and adapters for diagnostic tests, Allen or hex wrenches, and a wrench for holding the regulator nut while loosening the line nut.

- Replacement Parts: Ensure you have the correct replacement parts for your specific vehicle make and model. This includes a new fuel pressure regulator diaphragm and any associated gaskets, O-rings, or seals that may need to be replaced. It is recommended to purchase new bolts for a secure installation.

By gathering all the necessary tools and materials before beginning the replacement process, you can ensure a smoother and more efficient repair experience.

Replacing Fuel Pressure Regulator in Volkswagen Tiguan: Step-by-Step Guide

You may want to see also