If you're experiencing issues with your 1985 Ford F250 fuel pump, you're not alone. Many owners of this vehicle have reported similar problems. The good news is that you can replace the fuel pump yourself, but it's important to note that it's a challenging task that will require some specialised tools and a lot of time spent underneath your vehicle. Before you begin, make sure your truck is on a flat and safe surface, and the engine is off. You will also need to drain the gas tank. You have two options: removing the fuel tank or removing the truck bed. Removing the fuel tank is more difficult and requires siphoning gas and using a car jack and stands, but removing the truck bed is easier and simply requires you to remove the bolts and disconnect the lighting and fuel filler cap. Once you've accessed the fuel pump, you can replace it with a new one and put your truck back together.

What You'll Learn

Siphoning gas and using a car jack

Siphoning Gas

There are a few different ways to siphon gas, but it's important to note that you should never siphon gas by mouth as it is extremely dangerous and can be life-threatening.

The first method involves creating pressure in the tank. You will need a gas can or another closed container to siphon the gas into, and a length of clear plastic tubing that is 1 inch (2.5 cm) in diameter. You will need two lengths of tubing, one long enough to reach deep into the gas tank, and another shorter length that will reach just inside the tank. Place the gas can on the ground near the opening of the car's gas tank. Feed both tubes into the tank, pushing the longer tube well into the gas tank and ensuring it is fully submerged in the gasoline. Push the shorter tube just a few inches into the tank so that both tubes sit side-by-side. Use a rag to create a seal around the tubes—this will increase the air pressure in the tank and help to displace the gas through the longer tube into the gas can. When you're ready, blow air into the short tube to increase the air pressure inside the tank. Monitor the flow of gas and, when it is flowing freely, you can cover the long tube and raise it above the level of the gas in the tank to stop the flow.

The second method involves using a siphon pump. Place a gas can on the ground beneath the tank and run the tubing from the tank to the can. Pump when you're ready, and gas should begin to flow freely. When you are nearing your desired amount of gas, raise the end of the tubing to stop the flow.

Using a Car Jack

Using a car jack can be dangerous, so it is important to take the proper safety precautions. Before you begin, make sure you are using the correct type of jack for your vehicle. Car jacks come in different shapes and sizes, and you need to ensure that the jack has the proper weight capacity to lift your vehicle safely. Check your owner's manual to see if your vehicle comes with a manufacturer-supplied car jack, and to find out where the safe placement of the jack is underneath the vehicle.

Once you have the correct jack and have identified the placement, place the jack properly underneath the vehicle. If you are using a scissor jack, insert the rod or place the wrench over the knob and begin to crank to the right. If you are using a hydraulic jack, pump the long handle up and down. Raise the car slowly until the desired height is reached.

When you have finished your repairs, lower the car and check the lug nuts. Use the jack to lift the vehicle off the jack stands, then remove them and slowly lower the vehicle to the ground. Recheck the tightness of the lug nuts with the car resting on the ground.

Fuel Injector Conversion: Upgrading a 1984 F350 for Better Performance

You may want to see also

Removing the heat shield

To remove the heat shield, grab your impact wrench and crawl under the truck. You will notice two sets of bolts. One set holds the heat shield in place, and the other set holds the fuel tank in place. First, locate the bolts that hold the heat shield. They will be aligned with the heat shield strap.

Be careful not to remove the bolts for the tank straps before removing the heat shield. Once you have removed the bolts, the heat shield will start to drop as you take it out. Place your knee against it so that it doesn't fall on you as you wiggle it free. Then, put it aside.

Fuel Pump Replacement Cost for a 2005 G35 Coupe

You may want to see also

Disconnecting the fuel tank

Step 1: Safety First

Before starting, ensure your 1985 F250 Ford is parked on a flat and safe surface with the engine turned off. This step is crucial for your safety and to avoid any accidental injuries.

Step 2: Siphon the Fuel

Before removing the fuel tank, it is essential to siphon the gas from it. Use a clear hose and an air pump to extract the fuel. This step ensures that the tank is empty or close to empty before proceeding.

Step 3: Elevate the Vehicle

Use a car jack to elevate your 1985 F250 Ford to a height of at least 18 inches above the ground. This step is necessary to provide enough space to comfortably work underneath the vehicle. Place the jack in the grooves along the frame of the truck.

Step 4: Remove the Heat Shield

Crawl under the truck and locate the heat shield. The heat shield is in place to protect the fuel pump. Use an impact wrench to remove the bolts holding the heat shield. Be careful not to mix up the bolts for the tank straps and the heat shield. Once the bolts are removed, slowly remove the heat shield and set it aside.

Step 5: Support the Fuel Tank

Place two floor jacks underneath the fuel tank to support it. Make sure the jacks are raised just enough to provide support. It is recommended to place soft padding between the jack stands and the tank to prevent any damage.

Step 6: Remove the Fuel Tank Bolts

Using your impact wrench, remove the long bolts from the fuel tank. Be careful not to force or rush this step, as it can result in damaging the mounting point. Once the bolts are removed, slowly lower the straps and twist them off.

Step 7: Lower the Fuel Tank

Ask an assistant to slowly lower the jack stands while you support the fuel tank. The front end of the tank might be a bit tricky to lower due to the connection to the fuel fill line. Use a 1/4 inch hex socket to disconnect the fuel fill line. Once the connection is released, your assistant can lower the jack stands further, and you can carefully pull the fuel tank out from under the truck.

Now that the fuel tank has been successfully disconnected, you can proceed to the next steps of replacing the fuel pump or performing any other necessary maintenance. Remember to exercise caution and follow safety protocols throughout the process.

Changing Fuel Filter: 2010 Nissan Cube Guide

You may want to see also

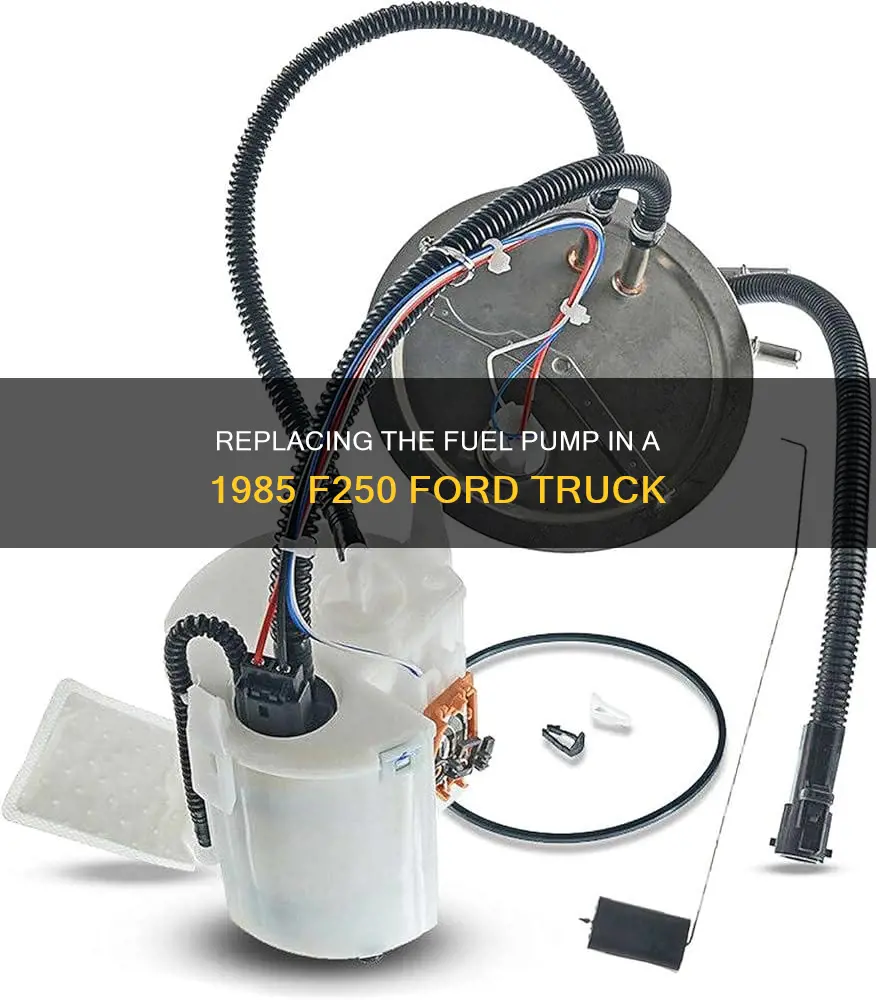

Locating and cleaning the fuel pump module

Whether you have removed the fuel tank or the truck bed, the process from here onwards remains the same. For those of you who removed the truck bed, the fuel tank can be found just behind the cab. Looking down at the tank, you will find a round fuel pump module bolted on top. Before removing the six bolts, disconnect the fuel outlay and relay lines from the module. You will also need to remove the evaporative hoses. They are fastened by safety clips which you pull and release to free from the module. A 3/8" Ford Fuel Line Disconnect Tool can be used here for detaching hard-to-remove fuel lines. Only purchase the aluminium ones—the plastic ones are no good.

Then, use a plastic brush to clean off the dust and dirt from the top of the module so that it doesn't fall into the tank when you remove the module. It is important to use a plastic brush when cleaning the module and tank, as a metallic brush can produce sparks, which you want to avoid when working near your fuel tank.

Next, take out a Sharpie pen and mark a spot on the module and the tank so you can align the new pump properly when installing it. The idea here is to know the exact positioning of the old module in order to identically align the new one.

Removing the old fuel pump assembly

After making your mark, grab your 8mm wrench and remove the six bolts that attach the gas pump module to the tank. Twist and lift the unit out. There is a good chance it will be stuck to the rubber seal underneath and won't budge very easily. If that is the case, very carefully use a flathead screwdriver to pry it up. Then lift the assembly out of the tank.

You will see that the fuel pump module is composed of many parts, including the fuel pump, fuel sender, and strainer. If you are a seasoned mechanic and you know what specific part is not functioning properly, you may just want to replace one of the individual parts. But if the pump is old, it's advisable to just replace the entire unit with a brand new one.

Fossil Fuels: Changing Climate, Changing Our Future

You may want to see also

Installing a new fuel pump assembly

Now that the old unit is out, you can start preparing to install the new fuel pump. First, you'll want to drop the new unit down into the fuel tank, aligning it with the mark you made earlier with your Sharpie. This mark ensures that you can properly align the new pump in the exact position as the old one. Once the new pump is in place, you can start reconnecting the various components.

Start by reconnecting the outlay and relay lines, as well as the evaporative hoses. These hoses are fastened by safety clips, which you can simply pull and release to free them from the module. If you're having trouble removing any hard-to-reach fuel lines, you can use a 3/8" Ford Fuel Line Disconnect Tool, but be sure to only purchase the aluminium ones as the plastic ones are not suitable for this task.

After reconnecting all the lines, you can move on to securing the new pump in place. Grab your 8mm wrench and replace the six bolts that attach the gas pump module to the tank. Tighten them securely, but be careful not to overtighten. With the new pump securely in place, you can now move on to reassembling your truck.

If you opted to remove the truck bed earlier, you'll now need to reinstall it and reconnect the lights, gas fuel filler cap, and neck clamp. On the other hand, if you removed the fuel tank, it will now need to be reinstalled. Make sure to reconnect all the straps and bolts, and don't forget to reattach the fuel fill line.

And that's it! You've successfully installed a new fuel pump in your 1985 Ford F-250. Remember to perform a final check to ensure that all connections are secure and components are properly installed before starting your engine. Now, you can enjoy improved performance and fuel efficiency from your newly installed fuel pump.

Marine Diesel Fuel Filter: Maintenance and Replacement Frequency

You may want to see also

Frequently asked questions

If you are having trouble starting your engine or you experience strange idling while on the road, it could be that your fuel pump is malfunctioning.

You can either remove the fuel tank or the truck bed to access the fuel pump. You will need to drain the gas tank and ensure your truck is on a flat and safe surface before starting.

You will need a clear hose and air pump for siphoning gas, a car jack and four stands, a flathead screwdriver, and a 3/8" fuel line disconnect tool.

First, siphon the gas from the tank. Then, elevate your truck using a car jack. Remove the heat shield and then the fuel tank or truck bed. Finally, locate and remove the old fuel pump assembly before installing the new one and putting your truck back together.