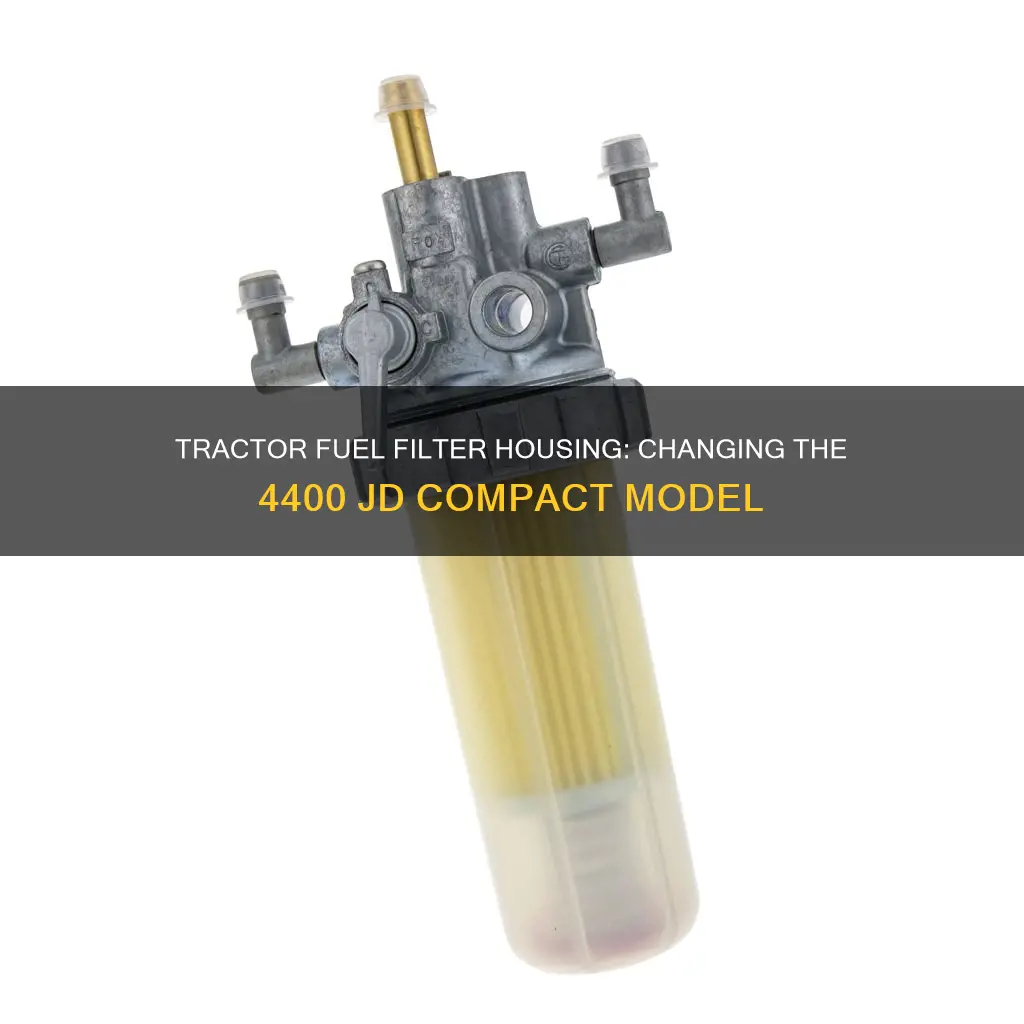

The John Deere 4400 compact tractor requires regular inspection and maintenance to ensure optimal performance and longevity. One essential aspect of this maintenance is changing the fuel filter and cleaning the housing. This task should be performed periodically, as outlined in the tractor's maintenance guidelines, to prevent fuel contamination and ensure the engine receives clean fuel for efficient combustion. While the process may vary slightly depending on the tractor's specific model and year, the fundamental steps involve accessing the fuel filter housing, typically located near the engine, draining or replacing the old filter, and installing a new filter, ensuring proper sealing and connections.

What You'll Learn

Removing the mounting screw

To remove the mounting screw from the fuel filter housing of your 4400 JD compact tractor, you will need to break the bolt/screw loose without causing any damage. Here is a step-by-step guide on how to do this:

Firstly, you cannot use a flame to heat the screw because there is fuel in the filter housing. Instead, pour hot water over the bleed screw to help loosen it. Use a 6-point box wrench on the bleed screw to avoid stripping the head. This will require some muscle, but you can develop more torque by slipping a small-diameter "cheater" pipe over the end of the wrench.

If this does not work, try using a corded or cordless hammer drill. Place the necessary bit in the drill and operate it in "hammer" mode to back the screw out. Note that some drills may not function in reverse in this mode. If this method also fails, the next step would be to use an impact gun.

Another suggestion is to start with a small strap wrench, which should be sufficient to loosen the screw.

If none of these methods work, you may need to replace the entire housing. You can purchase a new housing for around $40, which may be a simpler solution.

Switching Motorcycle Engines: Carburetor to Fuel Injection

You may want to see also

Using a hammer drill to loosen the screw

To loosen a screw with a hammer drill, you will need to use the drill's normal setting, not the hammer setting. The hammer setting on drills will push the bit in and out axially, as if you were hammering the back of the drill as the bit turns. This is designed to help bust up hard materials when drilling.

To loosen a screw, you will need to use the drill's rotational driving force. To do this, place the correct screwdriver bit into the drill. Ensure you have the right size and type of screwdriver bit for the screw head you are dealing with. Once the bit is secure in the drill, place the tip of the bit into the head of the screw and apply gentle pressure while pulling the trigger on the drill. Start slowly and increase the speed and pressure as needed.

It is important to wear eye protection when using power tools, as well as gloves to protect your hands. Be sure to keep your hands clear of the drill bit while it is in motion to avoid injury.

If you are having trouble loosening the screw, you may need to apply a penetrating oil such as WD-40 to the screw to help loosen it. Allow the oil to sit for a few minutes before attempting to loosen the screw again. You can also try using an impact driver, which is designed to help rotate stuck fasteners.

How to Change Your Toyota Highlander's Low Fuel Indicator

You may want to see also

Using a wrench on the bleed screw

To change the fuel filter housing on a John Deere 1050 tractor, you'll need to start by loosening the air bleed screw. Here's a step-by-step guide for using a wrench on the bleed screw:

First and foremost, ensure you have the correct wrench for the job. In this case, a 6-point box wrench is recommended to avoid stripping the head of the bleed screw. Place the 6-point box wrench on the bleed screw securely. You may need to apply some muscle and torque to break the screw loose, especially if it has been in place for a long time. If you have access to a cheater pipe, you can slip it over the end of the wrench to gain more torque and make it easier to loosen the screw.

Once the wrench is securely in place and you have applied some initial force, you can continue to slowly apply more torque. It is important to be cautious and not use excessive force, as stripping the head of the screw can cause further complications. If the screw is particularly stubborn, you may need to apply some heat. However, be cautious as the screw is located near fuel components. A suggested method is to pour hot water on the bleed screw to help loosen it.

If the screw still does not loosen, you may need to resort to a hammer drill. Place the appropriate bit in the drill and set it to "hammer" mode. Carefully use the drill in reverse to attempt to back the screw out. If this method also fails, an impact gun can be used as a last resort. Remember always to exercise caution when using power tools to avoid damage to the tractor or injury to yourself.

Once the bleed screw is loosened, you can proceed with the rest of the steps to change the fuel filter housing. Remember to refer to the tractor's manual for specific instructions and safety precautions. Changing the fuel filter housing is a maintenance task that ensures the tractor's optimal performance and longevity.

By following these steps and using the appropriate tools, you can effectively loosen the bleed screw and proceed with changing the fuel filter housing on your John Deere 1050 tractor.

Fuel Injector Maintenance: When to Change and Why It's Important

You may want to see also

Replacing the entire housing

To replace the entire fuel filter housing on your John Deere 1050 tractor, you can purchase a new housing for around $40 from Hoye Tractor or JD. First, ensure you have the necessary tools, such as a strap wrench, box wrench, hammer drill, or impact gun. Then, follow these steps:

- Remove the old housing by loosening the mounting screw with the appropriate tool. You may need to use hot water or a cheater pipe to gain more torque and break the screw loose.

- Install the new housing by screwing it into place with the new mounting screw. Ensure it is tightened securely.

- Check for any leaks around the fuel filter housing and bleed screws.

- If needed, replace the O-rings to prevent leaks.

By replacing the entire housing, you can ensure a secure fit and avoid potential leaks. This process may be more straightforward and cost-effective than attempting to repair individual components.

It is important to follow safety precautions when working on tractor maintenance and to refer to your tractor's manual for specific instructions and part numbers.

Air Flow Sensor Adjustment for Better Fuel Economy

You may want to see also

Upgrading the fuel filter

Step 1: Understanding the Fuel Filter Setup

Before upgrading, it's essential to understand the current fuel filter setup on your tractor. The John Deere 4400 tractor typically comes with a factory fuel filter that is rated at 19 microns. However, newer models like the 4320 series feature a different filter setup with a 5-micron fuel filter. Understanding these differences can help you choose the right upgrade option.

Step 2: Sourcing the Right Parts

When upgrading the fuel filter, you'll need to source the appropriate replacement parts. This typically includes a new fuel filter housing and a filter kit. The cost of these parts can vary, but they are generally affordable and easily accessible. In addition, you may need to purchase a bracket to secure the new fuel filter assembly.

Step 3: Disassembling the Old Fuel Filter Housing

Before installing the upgraded fuel filter, you'll need to carefully remove the old fuel filter housing. This process may vary depending on your tractor model. Refer to your tractor's manual for specific instructions. Make sure to have a plan for containing and disposing of any fuel that may spill during the process.

Step 4: Installing the Upgraded Fuel Filter

Once you have the new fuel filter housing and filter kit, carefully install them according to the manufacturer's instructions. Ensure that all connections are secure and tight to prevent leaks. If you're unsure about the placement or fit, refer to online resources or seek advice from experienced mechanics or tractor enthusiasts.

Step 5: Testing and Verification

After installing the upgraded fuel filter, it's crucial to test the tractor to ensure it functions correctly. Start the tractor and check for any leaks around the new fuel filter housing. Pay attention to any unusual noises or performance issues. If everything seems normal, you can be confident that the upgrade was successful.

Step 6: Regular Maintenance and Care

To ensure the longevity of your upgraded fuel filter, perform regular maintenance as recommended by the manufacturer. This may include periodic inspections, cleaning, and replacement of the fuel filter element. By following the maintenance schedule, you can maximize the performance and lifespan of your upgraded fuel filter.

When to Replace Your Ram 2500 Diesel Fuel Filter

You may want to see also

Frequently asked questions

It is recommended that you change the diesel fuel filter on your 4400 JD compact tractor every 500 hours.

The engine fuel filter part number for a 4400 JD compact tractor is M801101.

It is recommended that you use Low Viscosity Hy-Gard, JDM J20D, or J20C oil when changing the hydraulic/transmission oil on your 4400 JD compact tractor.

To remove a stuck mounting screw, you can try using a strap wrench or a hammer drill in "hammer" mode to back out the screw. You can also try pouring hot water on the bleed screw to loosen it.