Calculating GPH fuel pressure is a crucial aspect of understanding the relationship between fluid flow and the pressure it generates. This knowledge is essential for designing and maintaining piping systems and fluid delivery mechanisms. To calculate GPH fuel pressure, one must first determine the flow rate in gallons per hour (GPH) and the cross-sectional area of the pipe in square inches. With these values, you can use a formula to convert GPH to PSI, expressing the pressure in pounds per square inch. Additionally, factors such as the type of fuel, desired horsepower, and fuel pressure come into play when estimating fuel needs and pump flow rate.

What You'll Learn

Calculating fuel consumption

For example, a naturally aspirated 500 horsepower engine with a BSFC of about 0.5 would consume 250 lbs. of fuel per hour:

500 X 0.5 = 250 lbs/hr.

The next step is to convert lbs/hr to gph (gallons per hour). To do this, divide the lbs/hr by 6, as there are 6 lbs in a gallon of fuel:

250 lbs/hr ÷ 6 = 41.67 gph

You can also calculate the lph (liters per hour) by dividing the lbs/hr by 1.6, as a liter of fuel weighs about 1.6 lbs:

250 lbs/hr ÷ 1.6 = 156.25 lph

It's important to note that the minimum flow rate should be calculated at your fuel system's operating pressure. For Carburetors, this is typically between 4-7.5 psi, while Fuel Injection systems operate at higher pressures, usually between 35-65 psi.

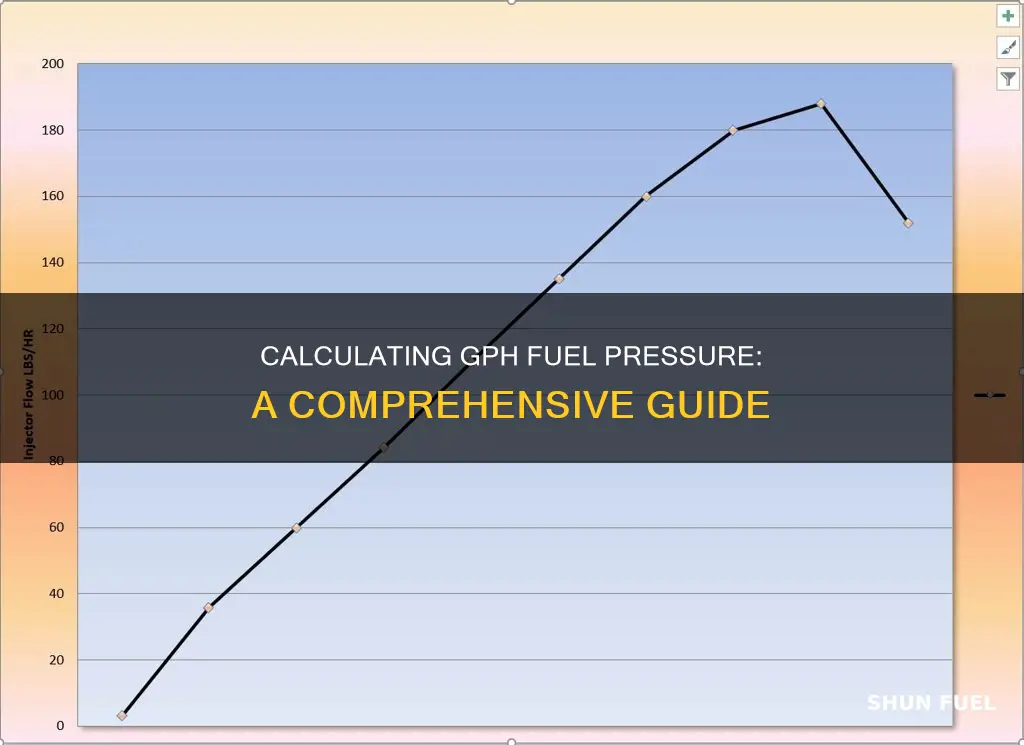

Additionally, keep in mind that fuel pumps are usually advertised by their free flow rate, which is the flow rate with no pressure. As pressure increases, the flow rate decreases. To find the flow rate at a given pressure, refer to a fuel pump's curve chart.

You can also use online calculators and converters to estimate fuel needs based on desired horsepower, fuel pressure, and fuel type. These tools will provide estimated fuel pump flow rates required to meet your specific needs.

Testing Fuel Pressure Regulator in '99 Camry: A Step-by-Step Guide

You may want to see also

Converting gallons per hour to PSI

When it comes to fuel pressure, knowing how to calculate and convert measurements is essential for optimising performance and ensuring safety. In this case, we're looking at converting gallons per hour (GPH) to pounds per square inch (PSI).

Understanding the Basics

Before diving into the conversion process, it's important to understand the distinction between these two units. GPH measures the flow rate of a liquid, indicating how much fuel is passing through a system in a given amount of time. On the other hand, PSI measures the pressure at which the liquid is being pumped through the system.

The Conversion Process

Converting GPH to PSI is not a direct process, as they are fundamentally different units. To make the conversion, you need to gather additional information about the system you're working with. This includes factors such as pipe size and length, pump performance, and friction losses. By taking these variables into account, you can apply Bernoulli's equation for an incompressible fluid to calculate the PSI from the known GPH.

Additionally, the specific gravity of the liquid being pumped is crucial for this conversion. The formula for converting GPH to PSI is: PSI = (GPH * specific gravity) / 8.33, where 8.33 is the weight of one gallon of water in pounds.

Practical Applications

Understanding how to convert GPH to PSI is valuable in various applications. For example, when selecting a fuel pump for an engine, you can use this conversion to determine if the pump can deliver the required fuel flow rate at a specific pressure. This ensures that the engine receives the necessary fuel supply for optimal performance.

Example Calculation

Let's walk through an example to illustrate the conversion process. Suppose you have a fuel system with a flow rate of 40 GPH, and you want to determine the corresponding PSI. You can use the formula mentioned earlier:

PSI = (GPH * specific gravity) / 8.33

First, you need to know the specific gravity of the fuel. Let's assume it has a specific gravity of 0.85. Now, plug the values into the formula:

PSI = (40 GPH * 0.85) / 8.33

PSI = (34) / 8.33

PSI ≈ 4.08

So, for this fuel system with a flow rate of 40 GPH and a specific gravity of 0.85, the corresponding PSI would be approximately 4.08.

Online Calculators

It's worth noting that there are online calculators available that can assist with this conversion. These calculators can simplify the process by guiding you through the necessary steps and providing quick and accurate results. However, it's always a good idea to understand the underlying formula and principles behind the conversion.

Understanding the G35 Fuel Pressure Regulator's Function

You may want to see also

PSI to GPM conversion

PSI (pounds per square inch) is a unit of pressure, while GPM (gallons per minute) is a unit of flow rate. This means that PSI and GPM cannot be directly converted. However, the Bernoulli equation for an incompressible fluid can be used to calculate the flow rate in GPM if certain other variables are known.

The Bernoulli equation states that for an incompressible, frictionless fluid, the sum of pressure (P), kinetic energy density, and potential energy density is constant:

P + 1/2 * ρ * v^2 + ρ * g * h = constant

Where:

- Ρ = density of the fluid

- V = velocity of the fluid flow

- H = height from the ground

- G = acceleration due to gravity

To determine the flow rate in GPM, the pressure at two different locations along the flow path (or pipe) needs to be known. Using the Bernoulli equation for fluid flow at a constant depth, the velocity can be calculated, and then the flow rate can be determined by multiplying the velocity by the pipe's cross-sectional area.

For example, let's consider a tank with a pressure of 72.0 PSI inside and an exit point with a pressure of 14.7 PSI (atmospheric pressure). By following the calculation steps outlined in the sources, the flow rate is determined to be 1411.57 GPM.

It is important to note that the calculation can be complex and involve multiple variables, including pipe length, diameter, fluid density, and fluid velocity. Online calculators and conversion charts can also be used to simplify the process of converting PSI to GPM or determining the flow rate based on PSI readings.

Fuel Rail Pressure Sensor Location: Where to Buy and Install

You may want to see also

Calculating GPM from PSI

PSI (pounds per square inch) is a unit of pressure, while GPM (gallons per minute) is a unit of flow rate. This means that PSI and GPM cannot be directly converted. However, it is possible to calculate the GPM from PSI if certain other variables are known.

To calculate the GPM from PSI, you can use Bernoulli's equation for incompressible fluid. Bernoulli's equation states that for an incompressible, frictionless fluid, the sum of pressure (P), kinetic energy density, and potential energy density is constant:

P + 0.5 * ρ * v^2 + ρ * g * h = constant

Where:

- Ρ (rho) is the density of the fluid

- V is the velocity of the fluid flow

- H is the height from the ground

- G is the acceleration due to gravity

To calculate the GPM, you need to know the pressure at two different locations along the flow path or pipe. Using Bernoulli's equation for fluid flow at a constant depth, you can set up the following equation:

P1 + 0.5 * ρ * v1^2 = P2 + 0.5 * ρ * v2^2

Where:

- P1 and P2 are the pressures at the two locations

- V1 and v2 are the velocities at the two locations

By rearranging this equation, you can solve for the velocity (v) at one of the locations:

V = sqrt((2 / ρ) * (P1 - P2))

Once you have the velocity, you can calculate the GPM by multiplying the velocity by the cross-sectional area of the pipe.

For example, let's say you have a tank with a pressure of 72.0 PSI, and the pressure at the exit point is 14.7 PSI (atmospheric pressure). The diameter of the pipe is 2.5 inches.

First, calculate the pressure difference between the two points:

P1 - P2 = (72.0 - 14.7) PSI = 57.3 PSI

Next, convert the pressure difference to pound-force per square foot:

3 PSI * (144 lbf/ft^2) / (1 PSI) = 8251.2 lbf/ft^2

Now, express the pound-force in terms of pound-foot/second^2:

2 lbf/ft^2 * 32.174 lb⋅ft/s^2 = 265,474.11 lb/ft⋅s^2

Multiply the difference in pressure by 2 and divide it by the density of water (62.4 lb/ft^3):

265,474.11 lb/ft⋅s^2 * 2 / 62.4 lb/ft^3 = 8,508.79 ft^2/s^2

Take the square root of this value to get the velocity in ft/s:

Sqrt(8,508.79 ft^2/s^2) = 92.243 ft/s

Calculate the cross-sectional area of the pipe using the diameter:

Area = pi * (diameter / 2)^2 = pi * (0.20833 ft / 2)^2 = 0.03409 ft^2

Finally, multiply the velocity by the cross-sectional area to get the GPM:

243 ft/s * 0.03409 ft^2 = 3.145 ft^3/s

To convert cubic feet per second to GPM, multiply by 448.83:

145 ft^3/s * 448.83 (GPM / ft^3/s) = 1411.57 GPM

So, the GPM for this example is approximately 1411.57.

It's important to note that calculating GPM from PSI can be complex and may require multiple conversions and mathematical steps. Online calculators and conversion tools can be helpful for performing these calculations accurately.

Testing Fuel Pressure Regulator in Honda Ridgeline: 2006 Guide

You may want to see also

Fuel pump calculator

Overview

This calculator helps you estimate fuel needs based on various factors, including desired horsepower, fuel pressure, and fuel type. By using this calculator, you can determine the fuel pump flow rate necessary to meet your needs.

Factors Affecting Fuel Flow

Horsepower

Horsepower is a critical factor in determining fuel flow requirements. Higher horsepower engines will generally require a greater fuel flow rate to function optimally.

Fuel Pressure

Fuel pressure also plays a significant role in fuel flow. As fuel pressure increases, the flow rate tends to decrease. Therefore, it's essential to consider the operating pressure of your fuel system when calculating fuel flow.

Fuel Type

Different types of fuel have varying power outputs, which directly impacts fuel consumption. For example, Gasoline, E85, and Methanol engines have different Brake-Specific Fuel Consumption (BSFC) values, affecting the amount of fuel needed per horsepower per hour.

Calculation Steps

To calculate the fuel flow rate in gallons per hour (GPH), follow these steps:

- Determine the fuel consumption in pounds per hour (lbs/hr): Multiply the desired horsepower by the BSFC value of the specific fuel type you are using. This will give you the fuel consumption in lbs/hr.

- Convert lbs/hr to GPH: Divide the fuel consumption in lbs/hr by 6, as there are approximately 6 lbs of fuel in a gallon. This will give you the fuel flow rate in GPH.

Example Calculation

Let's say you have a naturally aspirated 500 horsepower engine running on gasoline, and you want to calculate the fuel flow rate.

Fuel Consumption in lbs/hr: First, we need to find the BSFC value for gasoline engines. From the given data, we see that gasoline engines typically have a BSFC value between 0.45 and 0.50. For this example, let's use a BSFC of 0.50. Multiply the horsepower (500) by the BSFC:

500 hp x 0.50 = 250 lbs/hr

Fuel Flow Rate in GPH: Now, convert lbs/hr to GPH by dividing by 6:

250 lbs/hr ÷ 6 = 41.67 gph

So, for this naturally aspirated 500 horsepower engine running on gasoline, you would need a fuel flow rate of approximately 41.67 GPH.

Considerations

It's important to note that these calculations provide an estimate, and there may be slight variations in the real-world performance of your engine. Additionally, fuel pumps are typically advertised by their free flow rate, which is the flow rate with no pressure. As mentioned earlier, as fuel pressure increases, the flow rate decreases, so be sure to refer to a fuel pump's curve chart to determine the flow rate at a given pressure.

When selecting a fuel pump, it's crucial to consult with a professional, such as your tuner or engine builder, to ensure you choose the appropriate fuel pump and injector size for your specific application.

Finding Fuel Pressure Issues in a 1999 GMC

You may want to see also

Frequently asked questions

Multiply the peak horsepower by the BSFC (Brake-Specific Fuel Consumption). This will give you the fuel usage in lbs/hr. Then, divide lbs/hr by 6 to get gph.

A gallon of fuel weighs 6 lbs. So, to get gph, divide lbs/hr by 6.

A litre of fuel weighs about 1.6 lbs. To get lph, divide lbs/hr by 1.6.

The fuel system's operating pressure for Carburetors is between 4-7.5 psi.

The fuel system's operating pressure for Fuel Injection is usually between 35-65 psi.