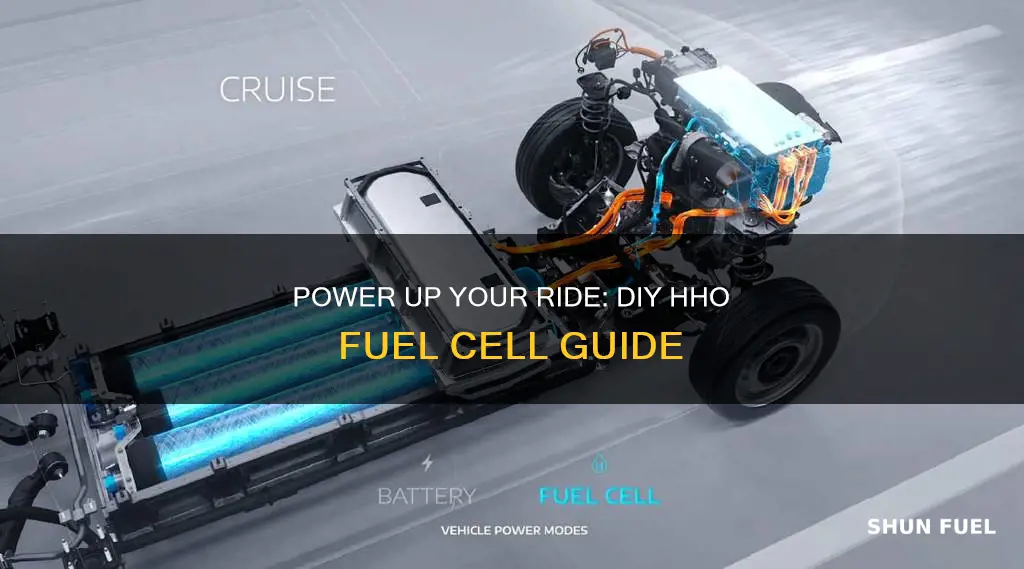

Building a hydrogen-hydrogen (HHO) fuel cell for your car can be a complex and potentially dangerous project. While HHO fuel cells have been proposed as a way to increase fuel efficiency and reduce emissions, they are not widely accepted as a viable alternative to traditional combustion engines. This guide will provide a basic overview of the components and steps involved in building an HHO fuel cell, but it is important to note that the process requires specialized knowledge and equipment, and the results may not meet the manufacturer's specifications or safety standards. Always prioritize safety and consult with professionals when dealing with automotive modifications.

What You'll Learn

- Materials and Components: Gather necessary materials like steel, electrolyte, and electrodes

- Cell Design: Construct a cell with a cathode and anode, ensuring proper spacing

- Electrolyte Preparation: Mix water and a strong acid to create a conductive electrolyte

- Power Supply: Connect the cell to a power supply to generate hydrogen gas

- Car Integration: Adapt the fuel cell to your car's engine for efficient operation

Materials and Components: Gather necessary materials like steel, electrolyte, and electrodes

To build a hydrogen-hydrogen (HHO) fuel cell for your car, you'll need to gather specific materials and components. Here's a detailed breakdown of the essential elements:

- Steel: High-quality steel is crucial for the construction of the fuel cell's anode and cathode plates. Opt for 304 stainless steel, known for its excellent corrosion resistance and durability. This material will form the foundation of your fuel cell's structure, ensuring it can withstand the chemical reactions occurring within.

- Electrolyte: The electrolyte is a critical component that facilitates the movement of ions between the anode and cathode. You can use a solution of water and a strong acid, such as sulfuric acid (H₂SO₄). The acid helps to dissociate the water molecules, creating hydrogen and hydroxide ions. It's essential to carefully measure and prepare the electrolyte solution to ensure optimal performance.

- Electrodes: Electrodes are the catalysts that drive the electrolysis process. You can use platinum or another precious metal as the electrode material. Platinum is highly efficient at facilitating the reduction of water to hydrogen gas. Ensure you obtain high-purity platinum electrodes to maximize the efficiency of your fuel cell.

- Other Components:

- Tank: You'll need a suitable container to hold the hydrogen gas produced by the fuel cell. Consider using a high-pressure gas tank made of aluminum or steel.

- Regulator: A pressure regulator is essential to control the output pressure of the hydrogen gas, ensuring it's safe and suitable for your car's engine.

- Pipeline and Hoses: These components will be used to connect the fuel cell to the car's engine and deliver the hydrogen gas.

- Power Supply: You might also consider adding a power supply unit to store excess energy generated by the fuel cell, which can be useful for auxiliary systems in your vehicle.

Remember, building an HHO fuel cell for your car requires careful planning and knowledge of electrochemistry. It's crucial to follow safety guidelines and ensure all components are properly assembled and maintained.

Solar Energy Cars: The Fossil Fuel-Free Future

You may want to see also

Cell Design: Construct a cell with a cathode and anode, ensuring proper spacing

When designing and constructing a hydrogen-hydrogen (HHO) fuel cell for your vehicle, the cell design is a critical aspect that directly impacts the efficiency and performance of the system. The primary goal is to create a cell that facilitates the electrochemical reaction between hydrogen and oxygen to produce electricity, with the cathode and anode playing pivotal roles.

The cathode and anode are the heart of the fuel cell, where the redox reactions occur. The cathode is typically made of a catalyst, often platinum, that facilitates the reduction of oxygen to water. This process involves the gain of electrons, which are then transferred through an external circuit to the anode. The anode, on the other hand, is where the oxidation of hydrogen takes place, releasing electrons and protons. Proper spacing between these components is essential to ensure optimal performance.

To construct the cell, start by preparing the cathode and anode materials. The cathode catalyst layer should be thin and evenly distributed to provide a large surface area for the reaction. A common choice for the anode is a porous material, such as a nickel-based alloy, which allows for the diffusion of hydrogen and the collection of electrons. Ensure that the anode and cathode are made of materials that are compatible with the electrochemical environment and can withstand the operating conditions.

Next, assemble the cell by placing the anode and cathode on either side of a separator or membrane. The separator is crucial as it prevents the direct contact of hydrogen and oxygen, which could lead to a safety hazard. It also facilitates the movement of protons from the anode to the cathode while allowing electrons to flow through the external circuit. Proper spacing between the anode and cathode is essential to prevent short circuits and ensure efficient electron transfer. A common approach is to use a membrane electrode assembly (MEA) where the catalyst layers are sandwiched between the anode and cathode, with the separator material integrated into the design.

The spacing between the anode and cathode should be optimized to balance reaction efficiency and gas utilization. Too little spacing may result in poor gas distribution and potential flooding, while excessive spacing can lead to increased resistance and reduced current density. Achieving the right spacing often involves trial and error, and it may require adjusting the dimensions of the catalyst layers or the overall cell geometry. Additionally, consider the gas flow channels and their design to ensure a uniform gas distribution across the cell, further enhancing the efficiency of the electrochemical reactions.

Bad Fuel Filter: A Hidden Cause of Car Death

You may want to see also

Electrolyte Preparation: Mix water and a strong acid to create a conductive electrolyte

To begin the process of creating a hydrogen-hydrogen (HHO) fuel cell for your vehicle, one of the most crucial steps is the preparation of the electrolyte. This component is essential as it facilitates the movement of ions between the electrodes, enabling the electrochemical reaction that produces hydrogen gas. The electrolyte is typically a solution of water and a strong acid, which provides the necessary conductivity for the cell to function.

The first step in electrolyte preparation is to gather the required materials. You will need distilled water, a strong acid such as sulfuric acid (H2SO4), and a container to mix the solution. It is important to use distilled water to ensure that no impurities are introduced into the electrolyte, as these can hinder the efficiency of the fuel cell. The acid is a critical component as it dissociates into hydrogen and sulfate ions, which are essential for the electrolysis process.

Next, carefully measure the amount of water and acid required for your specific fuel cell design. The ratio of water to acid is crucial and can vary depending on the cell's specifications and the desired concentration of the electrolyte. A common ratio is 3 parts water to 1 part acid by volume, but it is important to consult the specific guidelines for your fuel cell project. For instance, a 3:1 ratio of water to sulfuric acid by volume is often used, but this can be adjusted based on the cell's requirements.

Once you have the correct measurements, carefully mix the water and acid in the container. It is essential to use a clean, dry container to avoid any contamination. Stir the mixture thoroughly to ensure that the acid is completely dissolved in the water, creating a homogeneous electrolyte solution. The mixing process should be done with caution, as the acid is corrosive and can cause burns if it comes into contact with your skin.

After mixing, allow the electrolyte to sit for a short period to ensure that the solution is stable. Check the pH level of the electrolyte using a pH meter or test strips to confirm that it is within the optimal range for your fuel cell. The ideal pH for an HHO fuel cell electrolyte is typically around 1 to 2, indicating a strong acidic solution. If the pH is too high, you may need to add more acid; if it is too low, you can dilute the solution with more water. This step ensures that the electrolyte is ready for use in your fuel cell setup.

UK Car Fuel Guide: Know Your Vehicle's Needs

You may want to see also

Power Supply: Connect the cell to a power supply to generate hydrogen gas

To generate hydrogen gas for your HHO fuel cell, you'll need a power supply that can provide the necessary electrical current to split water molecules into hydrogen and oxygen gases. This process is known as electrolysis. There are various types of power supplies you can use, but for simplicity and efficiency, a DC (direct current) power supply is often recommended. Here's a step-by-step guide on how to connect the fuel cell to a power supply for hydrogen gas generation:

- Choose a Power Supply: Select a DC power supply that can provide a stable voltage and current suitable for your electrolysis setup. The voltage and current requirements will depend on the size of your fuel cell and the desired hydrogen production rate. Typically, a power supply with a voltage of around 12V to 24V and an adjustable current output is ideal. Ensure it has a sufficient power output to drive the electrolysis process effectively.

- Set Up the Electrolysis Setup: Prepare your electrolysis apparatus, which consists of a water tank, an electrolyte (such as a diluted sodium hydroxide or potassium hydroxide solution), two electrodes (anode and cathode), and a power supply. Place the electrodes in the water, ensuring they are fully submerged. The electrodes will be connected to the power supply, and the electrolyte will facilitate the electrolysis reaction.

- Connect the Power Supply: Connect one terminal of the power supply to the anode electrode and the other terminal to the cathode electrode. This setup will create an electric field within the electrolyte, driving the electrolysis process. When the power supply is activated, it will provide the necessary current to split water molecules (H2O) into hydrogen (H2) and oxygen (O2) gases at the respective electrodes.

- Monitor and Control: Keep an eye on the electrolysis process and the gas production. You can use a gas analyzer or a simple gas collection method to measure the hydrogen gas output. Adjust the power supply settings if needed to optimize gas production. It's important to maintain a consistent and controlled environment for efficient hydrogen generation.

- Safety Precautions: When working with hydrogen gas, safety is crucial. Ensure proper ventilation in the workspace to prevent gas buildup. Always handle the power supply and electrodes with care to avoid short circuits or electrical hazards. Additionally, be cautious of the electrolyte's chemical properties and follow safety guidelines when handling it.

By connecting the fuel cell to a suitable power supply and utilizing the electrolysis process, you can generate hydrogen gas for your HHO fuel cell system. This method provides a sustainable and cost-effective way to produce the required hydrogen for powering your vehicle. Remember to adapt the process to your specific fuel cell requirements and always prioritize safety during the construction and operation of your HHO fuel cell system.

Unleash Savings: Understanding Company Car Fuel Cards

You may want to see also

Car Integration: Adapt the fuel cell to your car's engine for efficient operation

The integration of a homemade HHO (Hydrogen-Hydrogen Oxide) fuel cell into a car's engine requires careful planning and technical expertise. Here's a detailed guide on how to adapt the fuel cell for efficient operation within your vehicle:

Engine Compatibility: Begin by assessing your car's engine type and size. HHO fuel cells are typically designed for smaller engines due to their power output. Ensure your engine can accommodate the additional components and modifications required for the fuel cell system. Consider the engine's power output and efficiency to determine the appropriate size and type of fuel cell to be installed.

Fuel Cell Design and Placement: Design a fuel cell that suits your car's dimensions and available space. The fuel cell should be compact and easily integrated into the engine bay or a designated compartment. Consider the placement of the cell to ensure proper ventilation and access for maintenance. You might need to modify the engine bay to create enough space for the fuel cell and associated components.

Hydrogen Supply System: Efficient operation relies on a reliable hydrogen supply. Design a system to produce and store hydrogen gas. This could involve building a water electrolysis unit to split water into hydrogen and oxygen, or exploring other methods like steam reforming of natural gas. Ensure the hydrogen storage is safe and complies with automotive regulations. The system should also include a regulator to control the hydrogen pressure, which is crucial for optimal fuel cell performance.

Engine Modifications: Modify your car's engine to work with the HHO fuel cell. This may include replacing the original fuel injection system with a custom setup that delivers HHO directly to the engine. You'll need to adjust the air-fuel mixture and timing to optimize combustion with the new fuel source. Consider using a programmable engine controller to fine-tune the engine's performance with the HHO fuel cell.

Efficient Power Management: Integrate the fuel cell's power output into your car's electrical system. Design a power management system that allows the fuel cell to charge the car's battery and provide additional power to the vehicle's electrical components. This ensures efficient energy utilization and may require modifications to the wiring and charging systems.

Remember, building and integrating an HHO fuel cell for your car is a complex project that requires a strong understanding of automotive engineering and electrical systems. It's essential to follow safety guidelines and regulations throughout the process.

Green Energy, Green Cars? Unveiling Fuel Cell Technology's Environmental Impact

You may want to see also

Frequently asked questions

An HHO fuel cell, also known as a hydrogen fuel cell, is a device that converts chemical energy from a fuel (often hydrogen) and an oxidizer (usually air or oxygen) into electricity through an electrochemical reaction. It produces electricity, heat, and water as byproducts, making it an efficient and environmentally friendly power source for vehicles.

Building an HHO fuel cell from scratch can be a complex and technical project. It requires knowledge of chemistry, electrical engineering, and mechanical skills. While it is possible for enthusiasts and DIY enthusiasts, it is recommended to start with a kit or follow detailed online tutorials to ensure safety and success.

The materials and components required include a hydrogen generator (such as a water electrolysis unit), a fuel cell stack, a control unit, a battery or capacitor for energy storage, and a car's electrical system integration. You will also need materials like catalysts, membranes, and various sensors for monitoring the cell's performance.

Safety is crucial when dealing with hydrogen and electricity. It is essential to follow proper ventilation, use appropriate safety gear, and ensure the system is well-insulated and protected from extreme temperatures. Regular maintenance, leak detection systems, and understanding the potential hazards of hydrogen gas are key to safe operation.

The legality of using HHO fuel cells in vehicles varies by region and local regulations. It is important to check and comply with emissions standards and vehicle modification laws. Additionally, while HHO fuel cells produce fewer emissions than traditional gasoline engines, proper disposal of waste products and understanding the environmental impact of hydrogen production are essential considerations.