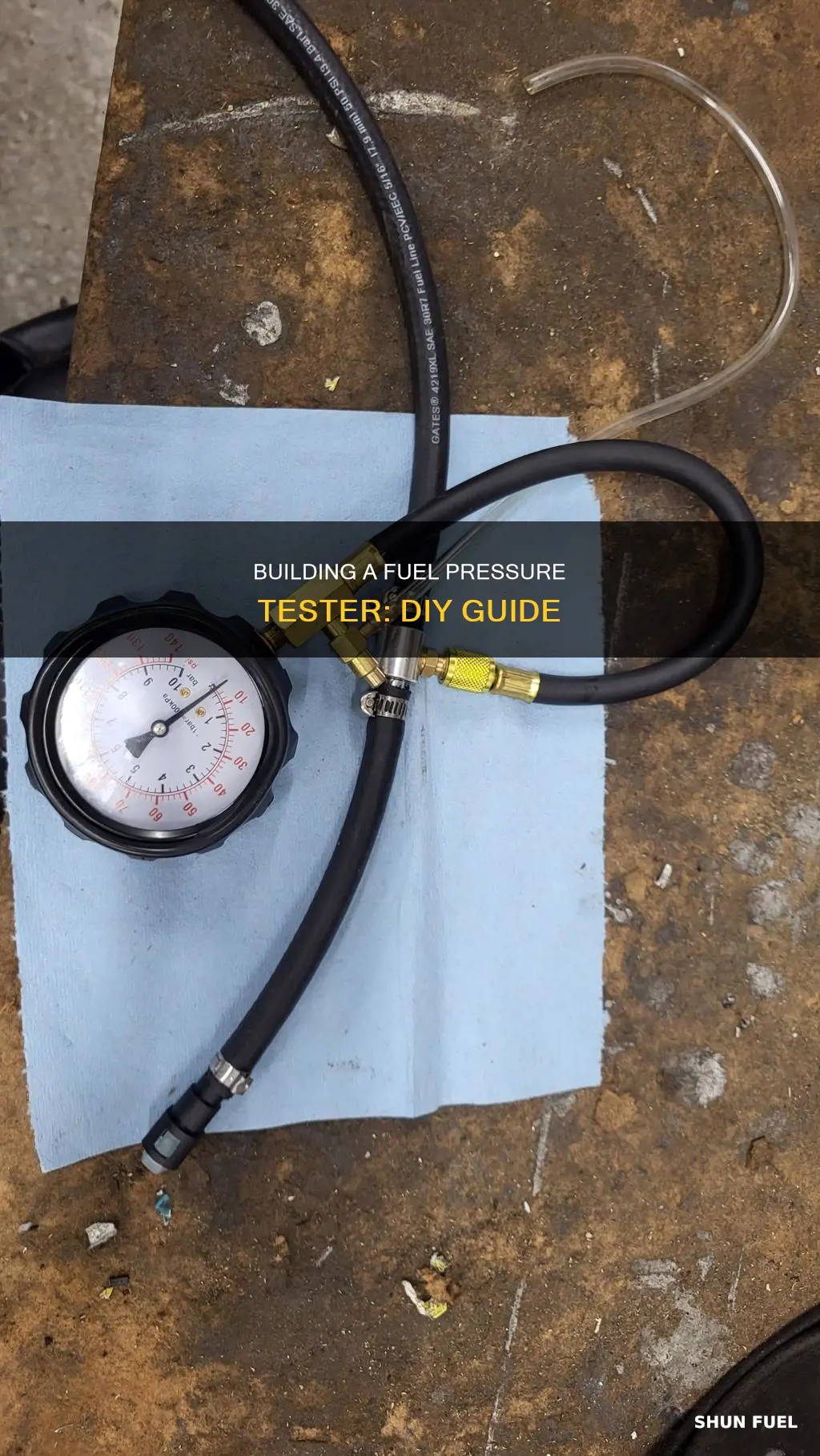

A fuel pressure tester is a device used to check the fuel pressure in a car's engine. It consists of a gauge attached to a fuel hose with multiple fittings that can connect to the fuel system of most vehicles. Testing fuel pressure is important as it can help identify issues with the engine's performance, such as slow starts, low performance, misfires, and stalling. Before testing fuel pressure, it is crucial to take safety precautions, such as working in a well-ventilated area and wearing protective gear, as fuel vapors are highly flammable. To use a fuel pressure tester, one must connect it to the fuel system, pressurize the system, and then read the pressure displayed on the gauge. This guide will explain the steps to build a basic fuel pressure tester.

| Characteristics | Values |

|---|---|

| Purpose | To test fuel pressure and flow |

| Use | Check for fuel pump malfunction |

| Tools | Fuel pressure tester, screwdriver, ratchets, sockets, etc. |

| Steps | Park the vehicle, apply the parking brake, allow the engine to cool down, locate the fuel pressure test port, place a rag under the test port, install the pressure tester, turn on the ignition, run the engine at a specific RPM, check for required pressure |

What You'll Learn

Safety precautions

Safety should always be the top priority when building and operating a fuel pressure tester. Here are some detailed, critical safety precautions to follow:

Personal Protective Equipment: Always wear the necessary personal protective equipment (PPE) when working with fuel and pressure testers. This includes safety glasses to protect your eyes from any debris or fuel splashes, and gloves to protect your hands. Gloves also help prevent leaving fingerprints or smudges on surfaces. It is also recommended to wear long sleeves and pants to protect your skin from any potential fuel exposure.

Ventilation: Fuel vapors are highly flammable and can quickly accumulate in enclosed spaces. Always work in a well-ventilated area to prevent the buildup of flammable vapors. Open doors and windows, or perform the work outdoors if possible. Ensure there is a constant flow of fresh air to minimize the risk of ignition.

No Smoking: Refrain from smoking or allowing any open flames or sparks near the work area. This includes refraining from smoking while working and ensuring cigarettes are properly extinguished before beginning work. Sparks or flames can easily ignite fuel vapors, leading to a dangerous explosion or fire.

Fire Extinguisher: Keep a fire extinguisher nearby at all times. This is a critical precaution in case of any accidental ignition or fire. Ensure the fire extinguisher is easily accessible and within reach. It is also essential to know how to use the fire extinguisher properly. Familiarize yourself with the correct procedure for operating it in case of an emergency.

Clean Work Area: Maintain a clean and organized work area. Keep the space free from clutter, rags, or any other flammable materials that could easily catch fire. A tidy work area reduces the risk of accidental ignition and allows for easier access to tools and equipment.

Fuel Handling: Handle fuel carefully and avoid spilling. Fuel spills can pose a fire hazard and cause environmental contamination. Use appropriate containers and carefully transfer fuel when necessary. Always clean up any spills immediately and dispose of waste properly, following local regulations.

Electrical Precautions: If working with electrical components, ensure the power is turned off before beginning work. Check for any live wires or connections that could pose a shock hazard. Use appropriate insulation or covers to protect electrical components from fuel exposure, as fuel can be conductive and pose a shock risk.

Pressure Release: When working with pressurized fuel systems, be extremely cautious when releasing pressure. Always follow the manufacturer's instructions for safe pressure release procedures. Never use force or attempt to release pressure without the proper tools and safety measures in place.

Emergency Preparedness: Be prepared for emergencies. Keep a first aid kit nearby in case of any injuries. Have an emergency response plan in place, including knowing how to respond to fires, spills, or other incidents. Ensure you have the necessary emergency contact information readily available.

By diligently following these safety precautions, you can help ensure your safety and the safety of those around you when building and operating a fuel pressure tester. Safety should never be compromised, and it is always worth taking the extra time to review and implement these critical measures.

Troubleshoot Your Boiler's Low Fuel Pressure Symptoms

You may want to see also

Fuel pressure test

A fuel pressure test can help identify issues with your vehicle's fuel pump, which could be the cause of problems with engine performance. Before you begin, ensure you are wearing safety gear such as gloves and safety goggles, and work in a well-ventilated area. Fuel vapours are highly flammable, so do not smoke or have anything nearby that could cause a spark.

To perform the test, you will need a fuel pressure test kit, which typically includes a gauge designed to read fuel pressure and a fuel hose. These can be purchased for $70 to $80. You will also need an assistant to help rev the engine during testing.

Firstly, consult your vehicle owner's manual to learn what readings you should expect. Then, open the hood and remove the cap from the fuel pump test point, usually located beside the fuel injectors. Attach the fuel hose to the test point and bleed the fuel pressure gauge to release any air before taking a reading.

Now, ask your assistant to turn the ignition on and take a reading of the vehicle's fuel pressure level. Make a note of the levels indicated on the gauge. Finally, remove the gauge and reseal the cap before closing the hood.

Interpreting the Results

If your fuel pressure gauge gives a reading of zero, the pump may be dead or not operational. This could be due to a loose connection or a faulty gauge. Test for power and ground to the fuel pump to determine if it is broken.

Low fuel pressure readings could indicate a malfunctioning fuel pump, such as a clogged fuel filter or a faulty pump. Check for loose gas caps, as this can prevent the tank from venting properly. Tighten the caps and re-test; if the readings do not change, you may need to replace the fuel filter. Low fuel pressure can cause a significant drop in performance, including reduced horsepower, difficulty starting the engine, and frequent stalling.

High fuel pressure readings suggest bad components, such as a failing fuel pump driver or a malfunctioning fuel pressure regulator. This can cause the engine to suffer, with potential issues including the vehicle belching black smoke, running rough, and smelling strongly of fuel.

Fuel Pressure Issues in Sport Trac: Causes and Solutions

You may want to see also

Flowmeter or glass container test

Safety First

Before performing any diagnostic tests, it is important to prioritise safety. Releasing fuel under pressure can cause fires and injuries. Wear safety goggles and gloves, work in a well-ventilated area, and avoid smoking or having anything nearby that could cause a spark.

Step 1: Fuel Pressure Check

Start by checking the fuel pressure. Start the car and let it idle. Install a fuel pressure gauge, run the pump, and note the pressure reading. Then, compare it to the manufacturer's specifications. If the pressure is low, address this issue. If the fuel pump is supplying sufficient pressure, proceed to the next step.

Step 2: Fuel Volume Test

The most accurate way to test fuel delivery is by using a flowmeter. However, if you don't have access to one, you can perform a timed fuel delivery test using a glass measuring container. Glass is recommended because fuel can corrode or fog up plastic.

Start the car, allowing the pump to run, and collect a fuel sample for five seconds. The pump should deliver a specific amount of fuel within this timeframe, which can be found in the manufacturer's specifications. You may need to convert millilitres per second to gallons per hour to make the comparison.

Fuel Pressure Sensor Failure: Impact and Solutions

You may want to see also

Interpreting fuel pressure readings

Zero Fuel Pressure Readings:

If your fuel pressure gauge reads zero, it indicates that the pump is not functioning or is dead. This could be due to a loose or detached pin at the gauge's end or a faulty fuel pressure gauge. To determine if the pump is genuinely broken, test for power and ground connections to the fuel pump.

Low Fuel Pressure Readings:

Low fuel pressure readings can be caused by a malfunctioning fuel pump or a clogged fuel filter. Check for loose gas caps, as improper tank venting can also lead to low fuel pressure. Tighten the gas caps and retest the readings. If there is no improvement, consider replacing the fuel filter. Low fuel pressure can cause a significant drop in vehicle performance, including reduced horsepower, difficulty starting the engine, and frequent stalling.

High Fuel Pressure Readings:

High fuel pressure readings suggest issues with specific components, such as a failing fuel pump driver or a malfunctioning fuel pressure regulator. High fuel pressure can lead to excessive fuel consumption, black smoke from unburned fuel, an overheating catalytic converter, and rough engine idle.

Ideal Fuel Pressure Range:

It's important to note that the ideal fuel pressure range varies depending on the engine. Older throttle-body injected systems may require as little as 10 PSI, while multi-port injection systems typically need around 60 PSI. Refer to your vehicle's owner's manual or a repair manual to determine the recommended fuel pressure for your specific engine.

Fuel Pressure Fluctuations:

Minor fluctuations in fuel pressure are normal and may not indicate an issue. However, if the fuel pressure reading fluctuates by 20% or more, it could suggest a problem with the fuel system or other components.

Fuel Pressure and Engine Performance:

Fuel pressure levels directly impact engine performance. High fuel pressure causes the engine to run rich, resulting in decreased fuel economy. On the other hand, low fuel pressure leads to a lean condition, where there is insufficient fuel in the combustion chamber, reducing engine performance and potentially causing stalling issues.

Fuel Pressure Damper: Signs of a Faulty One

You may want to see also

Troubleshooting

Before you build a fuel pressure tester, you should try to establish whether there is a fuel issue in the first place. Check that there is gas in the tank, even if the gauge indicates a full tank, as the gauge could be faulty. If there is gas in the tank, the next step is to verify that the fuel pump works. To do this, ask an assistant to turn the ignition switch to "On" and listen for a two-second whirring, humming, or series of rapid clicks as the fuel pump pressurizes the fuel line to the engine. If there is no noise, this means the pump is not getting power or has failed. In this case, check the fuel pump fuse and relay. If both are good, check the wiring to the pump. If voltage is present when turned to "on", then the pump has failed. If there is no voltage at the pump, check the wiring and connections.

Once you have established that there is a fuel issue, you can build a fuel pressure tester to help diagnose the problem. Fuel pressure tester kits consist of a fuel gauge and the fuel hose it is attached to. You can get your hands on a basic fuel pressure test kit for $70 to $80. Before using the kit, make sure to perform these steps in a well-ventilated area with a fire extinguisher nearby, as fuel vapors are highly flammable.

To use the fuel pressure tester, first, open the hood and remove the cap attached to the fuel pump test point. Then, attach the fuel hose to the fuel pump test point. Ask your assistant to activate the ignition and read the vehicle's fuel pressure level. Take note of the levels indicated on the gauge. If the fuel pressure is too high or too low, the vehicle's performance will drop significantly.

If the fuel pressure gauge gives a reading of zero, this could be because the pin at the end of the gauge has come loose, or because the fuel pressure gauge is faulty. Be sure to test for power and ground to the fuel pump to see if it is broken.

If the fuel pressure gauge gives a low reading, the fuel pump might be malfunctioning. For example, the fuel filter might be clogged or the pump itself might be faulty. Check for loose gas caps that might be preventing the tank from venting properly. If the readings do not change after the gas caps have been tightened, you might need to change the fuel filter.

If the fuel pressure is too high, the engine's performance will suffer. The vehicle might belch black smoke, run rough, and reek of fuel. High fuel pressure readings could be caused by bad components, such as a failing fuel pump driver or a malfunctioning fuel pressure regulator.

Mounting Fuel Pressure Regulators: The Right Spot Matters

You may want to see also

Frequently asked questions

You will need a fuel pressure test kit, which includes a gauge designed to read fuel pressure and the fuel hose it attaches to. You will also need safety equipment, including safety glasses and gloves, and a fire extinguisher.

First, ensure your vehicle's engine is cold, then pop the hood and locate the Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting. Turn the ignition to "on" and check the psi reading.

This depends on the engine. Older throttle-body injected systems may need as little as 10 psi, while multi-port injection can see as high as 60 psi. Check your vehicle's repair or owner's manual for specifications.

Low fuel pressure could be caused by a clogged fuel filter or a failing fuel pump. High fuel pressure could be caused by a faulty fuel pump driver or a malfunctioning fuel pressure regulator. In either case, if you are unable to fix the issue, consult a mechanic.