Bleed fuel lines in your car to ensure optimal performance and safety. This process involves removing air bubbles from the fuel system, which can cause issues like poor fuel efficiency, stalling, and even engine damage. By following a few simple steps, you can bleed the fuel lines yourself, saving time and money. This guide will walk you through the process, ensuring your vehicle runs smoothly and reliably.

What You'll Learn

- Prepare Tools: Gather fuel line bleeding kit, wrench, and safety gear

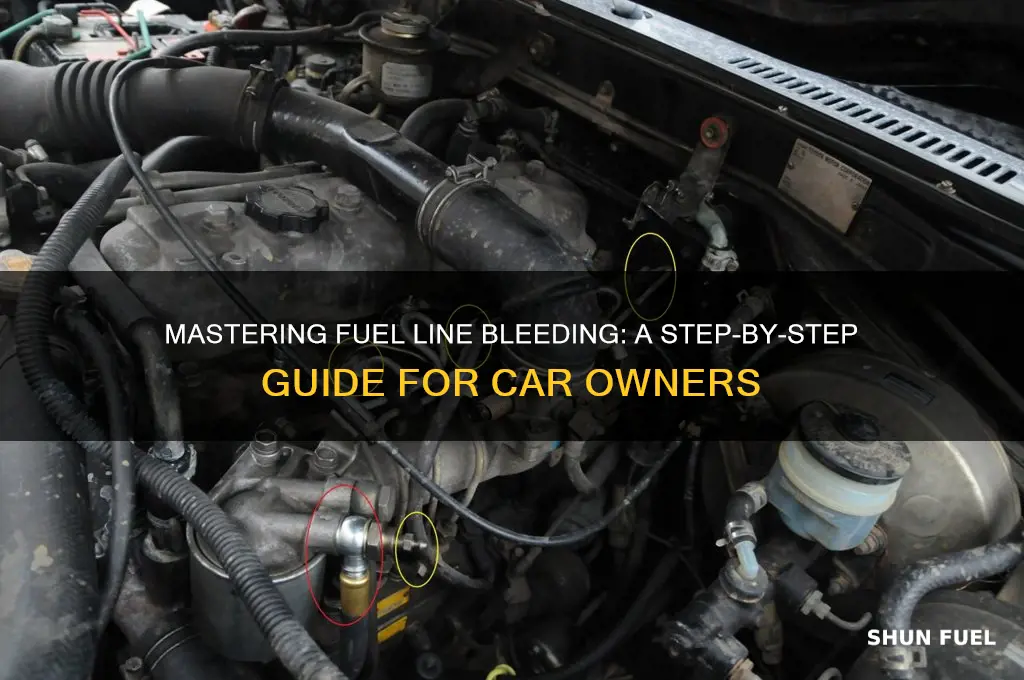

- Locate Lines: Identify fuel lines under hood, noting their positions and connections

- Bleeding Process: Use a pump or gravity to remove air bubbles from the line

- Venting: Ensure fuel tank and lines are properly vented to prevent vacuum lock

- Test: Check for leaks and proper fuel flow after bleeding

Prepare Tools: Gather fuel line bleeding kit, wrench, and safety gear

Before you begin the process of bleeding a car's fuel lines, it's crucial to ensure you have the necessary tools and safety equipment. This preparation will not only make the task more efficient but also guarantee a safe working environment. Here's a comprehensive guide on what you need to gather:

Fuel Line Bleeding Kit: This is the primary tool for the job. It typically includes a specialized fuel line bleeding kit designed for cars. This kit usually consists of a small, flexible tube with a pressure-release valve at one end. The tube is connected to a pump or a vacuum source, which helps in removing air bubbles from the fuel lines. Look for a kit that is compatible with your vehicle's fuel system.

Wrench: You will need a wrench to loosen and tighten the fuel line fittings. It's essential to have a wrench that fits the size of the fittings on your car. Most vehicles use 1/4-inch or 3/8-inch fittings, so ensure you have the appropriate wrench for these sizes. Wrenches are available in various types, including adjustable and fixed-size, so choose one that suits your preference and the accessibility of the fuel lines.

Safety Gear: Working on a car's fuel system requires caution to prevent any accidents. Here's what you should consider:

- Gloves: Protect your hands with a pair of thick, durable gloves. This is important to avoid direct contact with fuel, which can be harmful, and to provide a better grip when handling tools.

- Safety Glasses: Eye protection is vital to shield your eyes from any potential splashes or debris. Choose safety glasses that fit comfortably over your prescription glasses, if applicable.

- Breath Mask (Optional): If you are working in a confined space or near the engine, a respirator or a simple breath mask can help filter the air and protect your respiratory system from inhaling fuel vapor.

Having these tools and safety gear ready will ensure that you are well-prepared to bleed the fuel lines of your car effectively and safely. It's always a good practice to double-check the compatibility of the tools with your vehicle's make and model to ensure a successful outcome.

Flex Fuel Flexibility: Can Your Car Run on 87 Octane?

You may want to see also

Locate Lines: Identify fuel lines under hood, noting their positions and connections

When it comes to bleeding fuel lines in a car, the first step is to locate the fuel lines under the hood. This process requires a good understanding of the vehicle's engine layout and fuel system. Here's a detailed guide on how to identify and locate the fuel lines:

Start by opening the hood of your car and examining the engine compartment. Locate the fuel tank, which is usually positioned at the front or rear of the engine bay. Fuel lines will extend from the tank to various components of the fuel system, such as the fuel pump, fuel filter, and injectors or carburetor. Take note of the following:

- Fuel Pump Line: This line is typically a larger diameter and carries high-pressure fuel from the tank to the fuel pump. It is often connected to the pump's inlet port.

- Return Line: The return line is responsible for sending excess fuel back to the tank. It is usually smaller in diameter and may have a slight bend or kink to allow for proper fuel flow.

- Fuel Filter Line: This line connects the fuel pump to the filter, which removes impurities from the fuel. It is often a smaller line and may have a filter housing attached.

- Injector/Carburetor Lines: Depending on your vehicle's setup, there might be multiple lines leading to the injectors or carburetor. These lines are usually smaller and may have different colors or markings to distinguish them.

Carefully examine the engine bay and identify the positions of these fuel lines. Note any connections, such as quick-connect fittings, clamps, or screws that secure the lines. It is crucial to understand the layout to ensure you bleed the correct lines and avoid any potential damage.

Additionally, look for any fuel pressure regulators, vacuum lines, or other components that might be connected to the fuel lines. These components play a role in maintaining the correct fuel pressure and should be considered during the bleeding process.

By thoroughly inspecting and locating the fuel lines, you can ensure that you have a clear understanding of the fuel system's layout, making the subsequent steps of bleeding the lines more efficient and effective.

Is Your Car's Fuel Gauge Accurate? Calibration Tips

You may want to see also

Bleeding Process: Use a pump or gravity to remove air bubbles from the line

The process of bleeding a fuel line in a car is an important maintenance task to ensure optimal fuel flow and engine performance. When air bubbles accumulate in the fuel line, they can restrict fuel delivery, leading to engine misfires, reduced power, and potential starting issues. Here's a detailed guide on how to bleed the fuel line using a pump or gravity to eliminate these air bubbles:

Using a Pump:

- Locate the fuel pump, which is typically found in the engine compartment. It is usually a small, electric or mechanical pump that sends fuel from the tank to the engine.

- Disconnect the fuel line from the pump. This may require removing a few clips or screws to access the line. Ensure you have a container or bucket to catch any fuel that may spill.

- Attach a fuel pump primer or a small hand pump to the disconnected fuel line. This step is crucial as it helps to prime the system and remove air.

- Start the engine and turn it to the 'on' position, but do not start it. This initial step allows the pump to prime and draw fuel into the line.

- Slowly turn the key to the 'start' position and listen for the engine to turn over. If it doesn't start, it indicates that air is still present in the line.

- Continue the priming process by turning the key on and off repeatedly until the engine starts. This action helps to dislodge air bubbles.

- Once the engine is running, keep it idling for a few minutes. This allows the fuel to flow freely, and you can check for any leaks around the connections.

- After a few minutes, turn the key off and disconnect the pump. Reattach the fuel line to the pump and secure it.

Using Gravity (for Vertical Lines):

If your fuel line is vertical and runs from the tank to the engine, gravity can be utilized for bleeding:

- Park the car on a level surface and ensure the engine is off.

- Locate the fuel line and identify the lowest point, which is usually near the engine.

- Disconnect the fuel line at this lowest point and place a container beneath it to catch any fuel that drains out.

- Remove any air caps or vents on the fuel tank to allow air to escape.

- Start the engine and let it run for a few minutes. The fuel will flow downward due to gravity, pushing any air bubbles along with it.

- After a few minutes, turn the engine off and disconnect the container. Check for any remaining air bubbles by reattaching the line and starting the engine again.

- If air bubbles are still present, repeat the process until the engine starts smoothly without any stalling.

Remember, when working with fuel lines, always exercise caution and ensure the engine is off before disconnecting any lines to avoid fuel spills and potential hazards.

Unleash the Power: How Hydrogen Fuel Cars Work

You may want to see also

Venting: Ensure fuel tank and lines are properly vented to prevent vacuum lock

Venting is a crucial step in the process of bleeding fuel lines in a car to ensure optimal performance and prevent issues related to vacuum lock. When a fuel system is not properly vented, it can lead to a buildup of pressure, causing the fuel lines to become tight and potentially restricting the flow of fuel. This can result in poor engine performance, reduced power, and even stalling. Therefore, it is essential to understand the importance of venting and how to do it effectively.

The fuel tank and lines need to be vented to allow air to enter the system, which is necessary for the proper operation of the fuel pump and the overall fuel delivery process. Over time, fuel lines can become clogged with contaminants, and the fuel pump may not be able to draw fuel efficiently, leading to a vacuum lock. This occurs when the fuel system becomes sealed, creating a vacuum that prevents the fuel from flowing freely. To prevent this, it is recommended to use a fuel line venting kit, which typically includes a vent valve and a small tube.

To begin the venting process, locate the fuel tank and identify the vent port, usually a small opening on the side or top of the tank. Insert the venting kit's tube into this port, ensuring a secure connection. The vent valve should be opened, allowing air to enter the fuel tank and lines. This step helps to release any built-up pressure and ensures that the fuel system is properly aerated. It is important to keep the vent valve open for a sufficient duration to allow for complete venting.

For vehicles with older fuel systems, you might need to locate the fuel pump and check for a built-in vent. Some fuel pumps have a small vent port that needs to be opened to allow air to enter the system. This is especially important if the fuel pump is located in the tank, as it needs to draw fuel efficiently. In such cases, you may need to temporarily disconnect the fuel pump electrical connection to access the vent port.

Proper venting ensures that the fuel lines and tank are free from vacuum lock, allowing for smooth fuel flow and optimal engine performance. It is a simple yet critical step in the fuel line bleeding process, and by following these instructions, car owners can ensure their vehicles' fuel systems are functioning correctly. Remember, regular maintenance and venting can help prevent common fuel system issues and keep the engine running smoothly.

Indy Car Fuel Tank: Size, Capacity, and Rules Explained

You may want to see also

Test: Check for leaks and proper fuel flow after bleeding

After you've completed the process of bleeding the fuel lines, it's crucial to verify that the system is functioning correctly and that there are no leaks. This step ensures that the fuel is being delivered efficiently to the engine, and any potential issues are identified early on. Here's a detailed guide on how to perform this test:

Step 1: Prepare the Vehicle

Before starting the test, ensure the car is in a secure and level position. Turn off the engine and allow it to cool down, especially if you've been working on it for an extended period. Engage the parking brake for added safety. Locate the fuel tank and identify the fuel lines that have been bled. Typically, there will be two main lines: one for the engine and one for the fuel pump.

Step 2: Inspect for Leaks

Start by inspecting the fuel lines and connections for any signs of leaks. Use a clean cloth or paper towel to wipe the areas where the fuel lines connect to the tank, pump, and engine. Then, gently squeeze the lines with your hands to check for any fuel seepage. If you notice any leaks, tighten the connections or replace the lines as necessary. Ensure that all fittings are secure and tight to prevent future issues.

Step 3: Check Fuel Flow

With the engine off, locate the fuel pump relay (it's usually near the engine compartment fuse box). Disconnect the relay to temporarily shut off the fuel pump. Now, listen carefully for any hissing or gurgling sounds, which could indicate a blockage or leak in the system. If you hear such sounds, it's essential to investigate further. Reconnect the relay and start the engine. Observe the fuel gauge; it should rise steadily, indicating proper fuel flow. If the gauge remains static or drops, there might be an issue with the fuel pump or lines.

Step 4: Road Test

For a comprehensive test, take the vehicle for a short drive. Pay close attention to the engine's performance, listening for any unusual noises and watching for any warning lights on the dashboard. During the drive, periodically check the fuel gauge to ensure it functions correctly. After the test, recheck the fuel lines and connections for any signs of damage or leaks that may have occurred during the drive.

Remember, this test is a critical part of the bleeding process, as it ensures the system's integrity and prevents potential engine issues caused by improper fuel delivery. Always exercise caution when working with fuel, and if you're unsure about any step, consult a professional mechanic.

A Historical Look at Gasoline's Role in Automotive Evolution

You may want to see also

Frequently asked questions

Bleeding a fuel line is a process to remove air bubbles from the fuel system, ensuring that the fuel flows efficiently to the engine. This is crucial for optimal engine performance and can help prevent issues like stalling or poor acceleration.

It is recommended to bleed the fuel line whenever you notice signs of air in the system, such as a sputtering engine, reduced power, or difficulty starting. Additionally, it's a good practice to bleed the lines after major repairs or when replacing fuel filters to ensure a clean and efficient fuel supply.

Common indicators include engine misfires, rough idling, or a noticeable drop in performance. If you hear a whistling sound from the fuel tank or notice that the fuel gauge is reading lower than expected, it might be an air bubble issue, and bleeding the lines could be necessary.

Bleeding the fuel line is a task that can be performed by car owners with some mechanical knowledge. It involves releasing the pressure and allowing air to escape from the system. However, if you're unsure or uncomfortable with the process, it's best to consult a professional mechanic who can ensure the job is done correctly.

You will typically need a fuel line bleeding kit, which includes a specialized tool to release the air. This kit usually consists of a small pump, a flexible hose, and a fitting that connects to the fuel line. Some kits also come with different adapters to fit various car models. It's essential to follow the manufacturer's instructions for your specific vehicle.