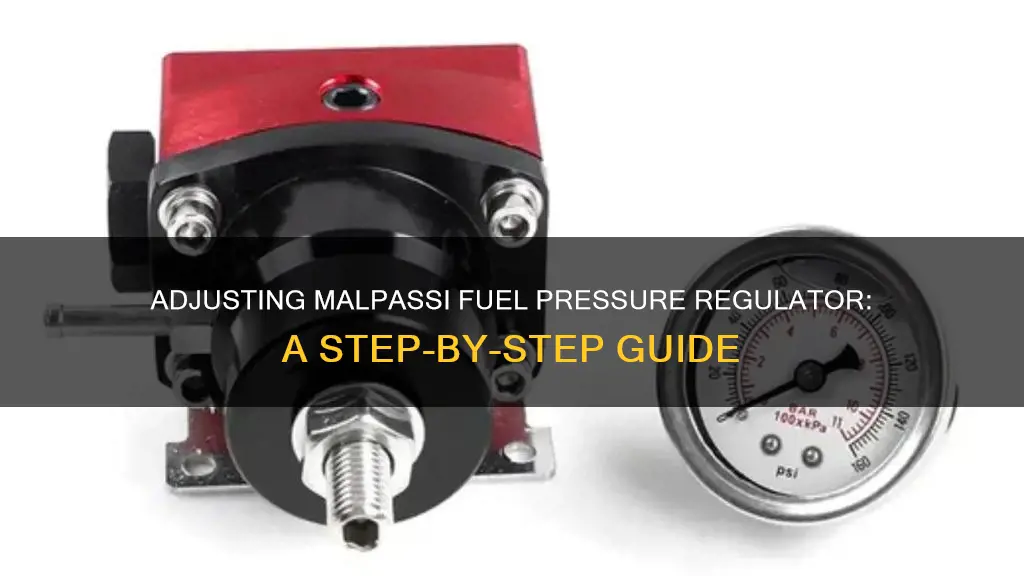

The Malpassi fuel pressure regulator is a device that helps manage fuel pressure in a car's engine, ensuring the fuel pump does not overwhelm the float valves and cause flooding or vapour lock issues. When adjusting the Malpassi regulator, it is important to first identify the correct fuel pressure for your vehicle, which can vary between 2-4 psi depending on the make and model of your car. Once you have determined the desired fuel pressure, you can adjust the regulator accordingly by locating the adjuster screw on top of the regulator body and using a suitable tool to turn it until the desired pressure is achieved. It is also important to ensure that the regulator is mounted correctly and that there are no leaks or clogs in the fuel system, as these can impact the effectiveness of the regulator.

What You'll Learn

How to check the fuel pressure on a '77 Spider 2000

To check the fuel pressure on a 77 Spider 2000, you will need to install a pressure gauge between the fuel pressure regulator and the inlet of the front carb. This will allow you to measure the fuel pressure and determine if any adjustments are necessary.

When checking the fuel pressure, it is important to ensure that the engine is running to get an accurate reading. For a 77 Spider 2000, the desired fuel pressure reading is around 3 psi. If the reading is lower than expected, there may be an issue with the fuel pump or fuel filter, or there could be a blockage in the fuel line.

If the fuel pressure is too high, it can cause the carburettor to overflow. In this case, you may need to adjust the fuel pressure regulator or check for any vacuum leaks, maladjusted linkage, or blockages in the jets. It is also important to ensure that the regulator is mounted correctly between the fuel pump and the carburettors.

Additionally, checking the float heights and inspecting the fuel pickup pipe and mesh filter screen in the fuel tank can help identify any potential issues affecting fuel delivery.

It is recommended to consult a mechanic or a specialist forum for specific advice if you are unsure about any aspects of adjusting or checking the fuel pressure on your vehicle.

Understanding the G35 Fuel Pressure Regulator's Function

You may want to see also

How to adjust the fuel pressure regulator on a Filter King regulator

To adjust the fuel pressure regulator on a Filter King regulator, you will need to locate the adjusting screw, which is found under the domed blind cap nut at the top of the regulator. Before making any adjustments, it is important to loosen the lock nut that is opposite the blind cap nut.

If the fuel pressure is too low, you should turn the adjusting screw half a turn in a clockwise direction. If the pressure is too high, turn the screw counter-clockwise, also only by half a turn. These adjustments should be made gradually until the desired pressure is reached.

It is important to note that adjusting the fuel pressure regulator can affect the performance of your engine. If the pressure is set too low, you may experience a fuel supply problem at high flow rates, leading to a lean air-fuel ratio. On the other hand, if the pressure is set too high, it can cause the carburettor to overflow.

To determine the correct fuel pressure for your engine, you may need to refer to the specifications provided by the manufacturer or seek advice from a mechanic or a specialist forum.

Additionally, it is recommended to use a fuel pressure gauge when making adjustments to ensure that you are achieving the desired pressure. An inline pressure gauge can be purchased relatively cheaply and will help you to make more precise adjustments.

Finally, once you have made the necessary adjustments and reached the ideal pressure, be sure to carefully tighten the lock nut to secure the position of the adjustment screw. Then, install and tighten the cap nut to complete the process.

Fuel Pressure and Spark Plugs: What's the Connection?

You may want to see also

How to tell if your fuel pump is working correctly

To adjust a Malpassi fuel pressure regulator, you will need to check the fuel pressure to your carburetors. You can do this by fitting a pressure gauge between the fuel pressure regulator and the inlet of the front carb. If you are getting a reading of below 2psi, and believe it should be closer to 3psi, you may need to adjust the regulator.

Now, here is how to tell if your fuel pump is working correctly:

A fuel pump is important for your car, and your vehicle will not be able to move without one. A malfunctioning fuel pump can cause poor fuel efficiency, stalling, and engine damage. A damaged fuel pump might make a loud, whining sound that you will hear from your gas tank. The pump may also make this noise if you are low on fuel or if the fuel in your tank is contaminated. The normal noise your pump makes is a low hum. If you hear a loud whine, this indicates there is a problem.

If your vehicle's fuel pump cannot get gas from the tank to the engine, you will have trouble starting your car. The car will struggle to start and run because the pump cannot push enough gas through. A worn pump loses its pressure and the engine is being starved of gasoline.

Your fuel pump does not stop pushing gas through to the engine once you have started your vehicle. It also pumps gas to meet your vehicle's speed. If the pump cannot produce a constant stream of gas at higher speeds, your vehicle's engine will sputter and threaten to stall.

If your engine is getting gas from the pump, even a lesser amount than needed, it will not likely stall. It will stall, however, if the pump causes your engine to overheat. An old and worn pump motor may get too hot and this can overheat your entire engine.

If you notice your vehicle loses power when you drive up steep inclines or load it up with cargo, your fuel pump could be the problem. As with faster speeds, the engine requires more gasoline to operate under stress. You will lose power if the pump is not working correctly.

Locating Fuel Pressure Checkpoints on a '98 Civic

You may want to see also

How to know if your float valves are weak

Float valves, also known as needle valves, are an essential component in a carburetted fuel system. They control the flow of fuel into the float bowl, ensuring the engine receives the necessary amount of fuel for combustion. Weak or faulty float valves can lead to various issues, from poor engine performance to severe damage. Here are some signs that indicate your float valves may be weak:

- Engine Stumble or Misfiring: If your engine stumbles, especially at higher RPMs, or starts misfiring, it could be a sign of valve float. Valve float occurs when the valves don't close properly at high engine speeds due to weak valve springs. This can cause a loss of power and engine misfiring as the valves don't follow the camshaft correctly, resulting in incorrect valve timing.

- Backfiring: Backfiring, or the sound of explosions coming from the exhaust or intake system, can be a symptom of valve float. It occurs when the fuel-air mixture in the cylinders ignites at the wrong time, often due to the valves not closing as they should, causing the unburnt mixture to escape through the exhaust.

- Loss of Power at High RPMs: Weak float valves can struggle to keep up with the engine's fuel demands at high RPMs, leading to a noticeable loss of power. This is because the valves may not be able to open and close quickly enough, disrupting the precise timing required for optimal engine performance.

- Fuel Overflow: If your carburettor experiences fuel overflow, it could be an indication that the float valves are not closing properly. This can lead to excess fuel flooding the engine, which can then leak out through the carburettor.

- Vacuum Leaks: While not always indicative of weak float valves, vacuum leaks can be a contributing factor. Float valves rely on a vacuum signal to function correctly, and leaks can disrupt this signal, leading to potential issues with valve operation.

It is important to note that weak float valves can be caused by various factors, including age, wear, or using an incorrect fuel pump. Regular maintenance and inspections are crucial to ensuring the float valves are in good condition. If you suspect weak float valves, it is recommended to consult a qualified mechanic for a thorough diagnosis and appropriate repairs.

Setting Fuel Pressure: Suntec Oil Pump Guide

You may want to see also

How to fix a hot running issue

To fix a hot-running issue, you can adjust the fuel pressure with a Malpassi regulator. Here are the steps:

Step 1: Check the Fuel Pressure

Use a pressure gauge to measure the fuel pressure. The ideal fuel pressure for most cars is around 2-3 psi, but it can vary depending on the specific make and model of your vehicle.

Step 2: Locate the Malpassi Regulator

The Malpassi regulator is typically located near the fuel pump or the carburettors. It is usually a small, cylindrical device with a knob or screw for adjusting the fuel pressure.

Step 3: Adjust the Fuel Pressure

Loosen the lock nut on the regulator with a suitable tool. Then, use a screwdriver to adjust the screw or knob on the regulator. Turn it clockwise to increase the fuel pressure and counter-clockwise to decrease it. Make small adjustments, as even a quarter turn can make a significant difference in fuel pressure.

Step 4: Re-check the Fuel Pressure

After making adjustments, re-check the fuel pressure with the gauge to ensure it is within the desired range.

Step 5: Test the Vehicle

Start the engine and let it run for a few minutes. Observe the engine's performance and listen for any unusual noises. If the hot-running issue persists or new problems arise, you may need to make further adjustments or consult a mechanic.

Note: It is important to be cautious when adjusting fuel pressure, as too much pressure can damage the fuel system and too little pressure can result in insufficient fuel delivery to the engine. Always refer to the vehicle's specifications and consult a professional if you are unsure.

Finding the Fuel Pressure Regulator in a 97 Suburban

You may want to see also

Frequently asked questions

Try applying some WD40 or a similar product to the adjuster screw to free it up.

The optimal fuel pressure setting depends on the specific carburettor and pump setup. A setting of 2-4 psi is commonly recommended, with 3 psi being a good baseline to try.

The regulator should be mounted between the fuel pump and the carburettors.