If you're looking to adjust your OSIR fuel pressure regulator, there are a few things you'll need to know. A fuel pressure regulator is an essential component of a vehicle or machine with an electric fuel pump, as it helps maintain fuel pressure and controls how much fuel goes into the engine. The OSIR fuel pressure regulator, in particular, is designed to ensure the pressure between the injector's inlet and outlet remains constant. This prevents too much pressure on the needle and seat assembly, avoiding flooding and drivability issues. To adjust the regulator, you will need to loosen the lock nut at the top and turn it clockwise to increase pressure or counterclockwise to decrease pressure. It's important to note that you should always use a fuel pressure gauge when making these adjustments, as incorrect adjustments can lead to excessive fuel pressure and even the risk of fire or explosion.

| Characteristics | Values |

|---|---|

| Brand | Holley |

| Product | Fuel pressure regulator |

| Price | $500 - $6,500 |

| Waiting time | 1 - 21 days |

| Mounting | Comes with a mounting bracket |

| Material | Aluminum |

| Inlet and outlet | 3/8" NPT |

| Adjusting pressure | Loosen the lock nut at the top, turn clockwise to increase pressure, and counterclockwise to decrease |

What You'll Learn

The importance of a fuel pressure regulator

A fuel pressure regulator is an essential component of any EFI system, ensuring the fuel rail can build up enough pressure to support the injectors. Without it, the fuel will flow straight through and not reach the injectors, causing them to fail. The regulator adapts the fuel supply to the fuel demand, maintaining a steady fuel supply even during dramatic changes in demand.

The regulator consists of a diaphragm that controls the bypass valve, which can open and close to adjust for a steady fuel delivery. When pressure is applied to the top of the regulator, the diaphragm is forced down, reducing the amount of excess fuel. This makes the fuel pumps work harder, and the fuel pressure increases. The regulator ensures the fuel injector can maintain the perfect ratio between fuel and boost.

The fuel pressure regulator is usually mounted after the fuel rail, ensuring the rail has priority in fuel flow. The valve in the regulator controls the amount of fuel that is bled from the rail by opening an outlet port, allowing fuel to flow back into the tank. This is called the base pressure, and it is adjusted to suit the injectors and fuel pump system being used.

The base pressure is set without any line connected to the vacuum/boost reference nipple. Once set, the vacuum/boost line is then connected. This ensures the pressure differential between the inlet and outlet of the injector remains constant, which is essential for the engine to function optimally.

Fuel Pressure Sensor Failure: Common Causes and Solutions

You may want to see also

How the Holley regulator works

The Holley regulator has two types: a low-pressure regulator with a maximum of 4# pressure and a higher-pressure version ranging from 4.5 to 9 PSI. The low-pressure regulator is designed for street use, while the higher-pressure version is suitable for full-throttle driving.

To adjust the Holley regulator, it is recommended to have the engine running. Start by turning on the electric fuel pump and adjusting the regulator to achieve the desired pressure. The flow of fuel seems to be necessary for the initial adjustment.

It is also important to consider the type of regulator you have, either a bypass or deadhead regulator. A bypass-type regulator requires a return line to get an accurate reading, while a deadhead regulator does not. A deadhead regulator is sufficient for street use, but if you engage in a lot of full-throttle driving, a bypass regulator is recommended to maintain a consistent fuel supply to the float bowl.

Additionally, you can purchase a repair kit that includes both low and high-pressure springs, allowing you to adjust the regulator to your specific needs.

Who Manufactures AC Delco Fuel Pressure Regulators?

You may want to see also

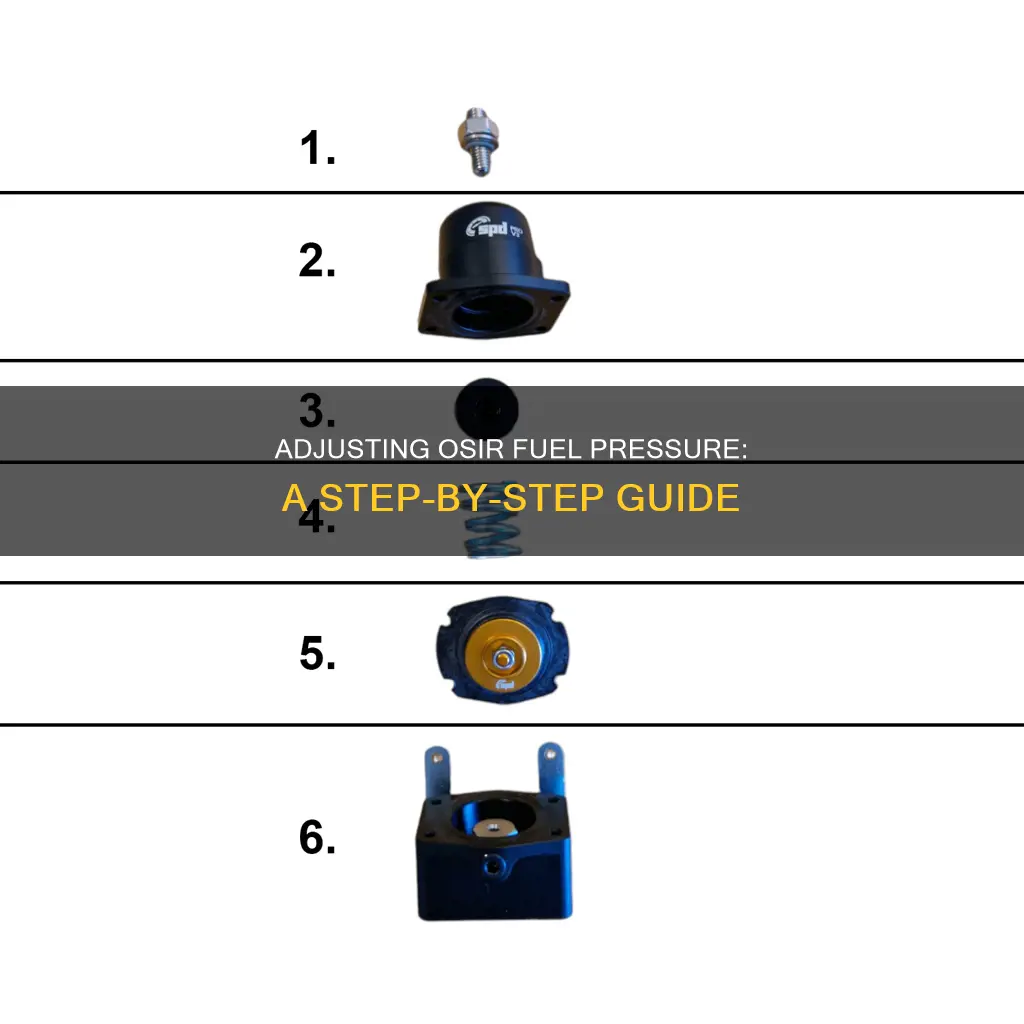

Adjusting the pressure

Firstly, it is important to understand that the Holley fuel pressure regulator comes factory pre-set, so adjustments may not be necessary. However, if you need to adjust the pressure to suit your engine's specific requirements, you can do so by following these steps.

Locate the lock nut at the top of the regulator. To increase the pressure, use a suitable tool to turn the lock nut in a clockwise direction. Conversely, to decrease the pressure, turn the lock nut in a counterclockwise direction. Make sure to refer to the Holley instruction manual for specific details on this process.

It is imperative that you use a fuel pressure gauge when making these adjustments. The gauge should be positioned between the carburetor and the fuel pressure regulator. If you have a high-pressure fuel pump, ensure that the regulator is placed between the regulator and the pump.

If your vehicle has two carburetors, plug each one into the available discharge ports. If you only have a single carburetor, plug one of the ports and feed the carburetor from the other port. Ensure that the fuel pressure regulator is mounted as close as possible to the fuel rails or the carburetor. Do not mount the regulator on hot surfaces such as exhaust manifolds to reduce the risk of fire and other hazards.

The Holley fuel pressure regulator can also be adjusted using the boost reference fitting. To do this, remove the vent plug and replace it with a barb fitting, which should then be connected to the vacuum source of the engine.

When making any adjustments, always ensure that all fuel connections are leak-proof. Holley fuel pressure regulators are designed to maintain their position once adjusted, so you won't have to worry about slippage due to pressure.

Incorrectly adjusting the Holley fuel pressure regulator can lead to excessive fuel pressure, which can cause the fuel system to flood. This, in turn, poses a risk of fire or explosion, so it is crucial to be cautious and refer to the instruction manual before making any adjustments.

Troubleshooting Low Fuel Pressure in an Equinox

You may want to see also

Placement of the regulator

When placing the fuel pressure regulator, there are a few key considerations to keep in mind. Firstly, it is important to ensure that the regulator is placed as close as possible to the fuel rails or the carburetor. This helps maintain the optimal fuel pressure in the electronic fuel injection system. The regulator should also not be mounted on hot surfaces such as exhaust manifolds to reduce the risk of fire and other potential dangers.

Another important factor to consider is the fuel pressure gauge's placement. The gauge should be located between the carburetor and the fuel pressure regulator. However, if you have a high-pressure fuel pump, the regulator must be placed between the regulator and the pump. This ensures accurate pressure readings and helps prevent excessive fuel pressure, which can lead to flooding and potential fire hazards.

Additionally, when dealing with multiple carburetors, each one should be plugged into the available discharge ports. On the other hand, if you have a single carburetor, one of the ports should be plugged, and the carburetor should be fed from the other port. This ensures proper fuel distribution and helps maintain the correct fuel pressure.

It is also worth noting that the fuel pressure regulator should be adjusted to maintain a constant pressure ratio between the inlet and outlet. The inlet and outlet measurements of 3/8" NPT help achieve this consistency. By following these placement guidelines, you can ensure the proper functioning of the fuel pressure regulator and maintain the overall performance of the engine.

Locating the Fuel Pressure Test on a 2005 Liberty

You may want to see also

Possible consequences of incorrect adjustments

Incorrect adjustments to a fuel pressure regulator can lead to a range of issues, some of which can be severe. Here are some possible consequences:

- Engine Performance Issues: An incorrect fuel pressure adjustment can result in an improper air-fuel mixture. This can cause a loss of engine power, decreased acceleration, and poor throttle response. In extreme cases, it can even lead to engine damage.

- Engine Misfires: A faulty fuel pressure regulator can cause the engine to misfire, either at idle or during acceleration. This is often accompanied by unusual engine noises, such as sputtering.

- Check Engine Light: Modern vehicles have monitoring systems that detect sensor failures. An incorrect fuel pressure adjustment can trigger a trouble code, causing the check engine light to illuminate on your dashboard.

- Fuel Leakage: A faulty fuel pressure regulator can lead to fuel leaks, which not only cause performance issues but also pose a safety hazard. Fuel leaks can result in dangerous situations, such as a car fire.

- Black Smoke from Exhaust: An incorrect fuel pressure adjustment can lead to a rich air-fuel mixture, resulting in black smoke coming from the exhaust pipe. This issue is typically associated with diesel engines, but it can also occur in gasoline engines with a faulty fuel pressure regulator.

- Vacuum Hose Filled with Gasoline: A defective fuel pressure regulator diaphragm can cause fuel to enter the vacuum system instead of the engine, leading to gasoline filling the vacuum hoses and intake manifold.

- Unburned Fuel in the Exhaust System: A faulty fuel pressure regulator can cause excess fuel to flow into the combustion chamber, leading to unburned fuel entering the exhaust system. This can result in an explosion of unburned fuel, which is highly dangerous and can cause the exhaust pipe to explode or the car to catch fire.

- Inconsistent Pressure Readings: While not directly related to incorrect adjustments, a faulty fuel pressure regulator can cause inconsistent pressure readings. This could be due to a faulty fuel pump or a dirty fuel filter.

Relieving Fuel Pressure: Changing Filters Safely

You may want to see also

Frequently asked questions

There are several symptoms that can indicate a faulty fuel pressure regulator, including decreased engine power, a whirring noise from the fuel pump, fuel leaks, and black smoke coming from the exhaust.

To adjust the pressure, loosen the lock nut at the top of the regulator. Turning the lock nut clockwise will increase the pressure, while turning it counterclockwise will decrease the pressure. It is important to use a fuel pressure gauge when making these adjustments to avoid the risk of fire or explosion due to excessive fuel pressure.

Ensure that all fuel connections are leak-proof and that the regulator is mounted on a cool surface away from hot components such as exhaust manifolds. Do not overtighten the lock nut, as this can lead to excessive fuel pressure and flooding of the fuel system.