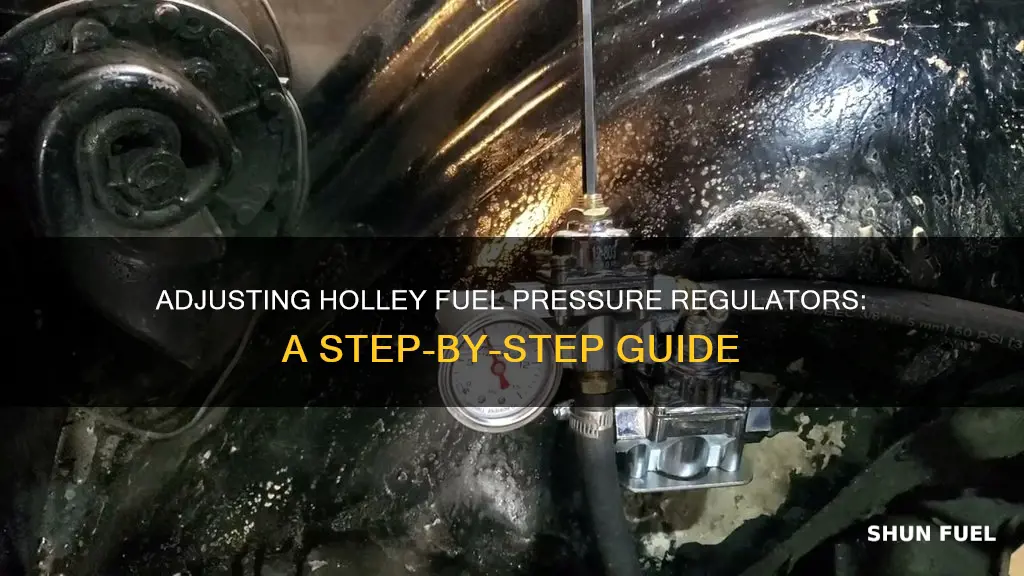

Adjusting a Holley fuel pressure regulator is a task that requires careful attention to detail. The process involves fine-tuning the regulator to ensure optimal fuel pressure, which is crucial for engine performance and fuel efficiency. While the specific steps may vary depending on the vehicle and regulator model, some key considerations include running the engine to ensure accurate adjustments, monitoring fuel pressure with a gauge, and understanding the desired pressure range for your specific carburettor. In addition, having the right tools and safety precautions in place is essential for a successful adjustment. This introduction sets the stage for a comprehensive guide on adjusting a Holley fuel pressure regulator, covering everything from preparation to troubleshooting common issues.

What You'll Learn

The engine should be running when adjusting the regulator

When adjusting the fuel pressure regulator on a Holley carburettor, it is best to have the engine running. This is because the fuel pressure can vary, and you need flow for the initial adjustment. With the engine not running but the pump on, you may only be able to get 3.5 lbs of pressure, and the adjustment will be more difficult.

To start, turn on the electric fuel pump and let it run for a while to build up some pressure in the system. Then, start the engine and make your adjustments with the engine running. This will give you a more accurate reading and allow you to fine-tune the regulator to the desired setting.

It is also important to note that there are different types of regulators, and you should be aware of which one you have. There are low-pressure Holley regulators that have a maximum pressure of 4 lbs, and there are also higher-pressure versions that can go from 4.5 to 9 PSI. Additionally, there are bypass-type regulators and deadhead regulators. A bypass-type regulator uses a return line to get an accurate reading, while a deadhead regulator does not. Deadhead regulators are suitable for street use, but if you do a lot of full-throttle driving, a bypass-type regulator is recommended to keep the float bowl full.

Finally, it is a good idea to have a fuel pressure gauge mounted where you can easily see it, especially if you are using a deadhead regulator. This will allow you to monitor the fuel pressure while driving and make any necessary adjustments.

Fuel Pressure Maintenance for the 93 240SX: Getting it Right

You may want to see also

A return line is required for a bypass-type regulator

A return line is an essential component of a bypass-type regulator in a fuel system. This setup, also known as a return-style or bypass regulator, offers several advantages over a deadhead-style fuel system.

In a bypass-type regulator, excess fuel pressure is bled off and dumped into a return line, which then recirculates the fuel back into the tank. This recirculation process provides numerous benefits, including improved reliability and performance. By maintaining a constant fuel pressure, the bypass regulator prevents pressure creep, reduces heat, and prolongs the life of the fuel pump.

The return line plays a crucial role in ensuring proper fuel pressure and preventing fuel system overpressure. It establishes a continuous flow of fuel within the system, allowing for consistent fuel delivery to the engine. Additionally, it relieves excess pressure that could build up if the fuel was not returned to the tank.

When installing a bypass-type regulator, it is important to use a return line that is appropriately sized. A return line that is too small can result in excessive backpressure, hindering the regulator's ability to effectively bleed off fuel and control the fuel pressure. Therefore, it is generally recommended to use a return line that is the same size as the feed line to ensure optimal performance.

The Holley 12-803BP fuel pressure regulator is an example of a bypass-type regulator that requires a return line. It features adjustable fuel regulation from 4.5 to 9 psi and is designed specifically for use with a return line back to the fuel tank.

Fuel Tank Pressure: What's the Cause?

You may want to see also

Deadhead regulators are okay for street use

Deadhead regulators are a simple and effective setup for fuel pressure regulation in carbureted engines. They are positioned between the fuel pump and the carburetor, and their function is to restrict fuel flow, thereby lowering fuel pressure. This type of regulator is commonly used in street cars and can adequately manage fuel pressure in engines with up to 400 horsepower.

The deadhead regulator's simplicity makes it a cost-effective choice for street use. It requires fewer components, connections, fittings, and lines, which translates to lower installation and maintenance costs. Additionally, the reduced number of connections decreases the potential for leaks. Deadhead regulators are typically designed with two ports, one inlet, and one outlet, although some modern versions feature three ports with one inlet and two outlets.

The performance of deadhead regulators in street applications is generally acceptable. They are designed to be normally open, allowing fuel flow until the pressure reaches its preset limit. This design does place an additional load on the fuel pump, as it operates at full capacity and pressure against the regulator. While this setup may pull more amperage from the charging system, it is not a significant concern for street cars that typically operate at part throttle.

For street use, deadhead regulators offer a straightforward and economical solution for fuel pressure regulation. They are widely available from manufacturers like Holley, Quick Fuel, Earl's, and Mr. Gasket, ensuring accessibility and ease of procurement.

Understanding Fuel Pressure Requirements for the 318 JD Engine

You may want to see also

Bypass-type regulators are better for full-throttle driving

Another advantage of bypass regulators is their ability to maintain fuel pressure stability and smoothness. The constant circulation of fuel throughout the system allows the regulator to respond quickly to changes in engine load, ensuring that the fuel bowls remain full and reducing the likelihood of lean-out conditions, especially during racing.

Additionally, bypass regulators do not suffer from the same issues of fuel heating, pump overworking, regulator hammering, and pressure creep that are commonly associated with deadhead regulators. This leads to increased longevity for both the fuel pump and the regulator.

When it comes to plumbing a bypass fuel regulator, manufacturers typically recommend using a -10 AN fuel line (or larger) from the tank to the pump and a -10 AN line from the pump to the regulator. The return line can be a -8 AN or -10 AN line. It is important to ensure that the return line does not spray fuel near the pickup inside the fuel tank to avoid aeration issues.

Troubleshooting Carburetor Fuel Pressure Loss After Engine Shut Off

You may want to see also

The Holley 12-804 and 12-803 regulators are the same except for the spring

The Holley 12-804 and 12-803 regulators are designed to control the fuel pressure from the fuel pump to the carburetor. They are fully adjustable, allowing users to regulate fuel pressure according to their engine's needs. Holley regulators come pre-set at the factory, eliminating the need for guesswork during initial installation.

The key difference between the 12-804 and 12-803 regulators lies in their pressure adjustment ranges. The 12-804 regulator offers adjustable fuel regulation from 1 to 4 psi, making it suitable for applications requiring lower fuel pressure. On the other hand, the 12-803 regulator provides adjustable fuel regulation from 4.5 to 9 psi, catering to setups that demand higher fuel pressure.

Both regulators feature similar specifications, including .220" (7/32") restriction, 3/8" NPT ports (1 inlet and 2 outlets), and a mounting bracket included in the package. These regulators are designed to prevent overloading the needle and seat assembly, which can lead to flooding or drivability issues.

It is worth noting that some customers have reported issues with the mounting holes on these regulators. The bracket mounting holes may not be threaded, requiring additional tapping before installation.

Installing a Vacuum Bypass Fuel Pressure Regulator: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Yes, the engine must be running to adjust the fuel pressure.

This depends on the type of regulator you have. There are low-pressure regulators that go up to 4# max and higher-pressure versions that go from 4.5 to 9 PSI.

The exact process may vary depending on your setup, but in general, you will need to locate the regulator and adjust it using a screwdriver or similar tool.

There are a few signs that your fuel pressure regulator may need adjusting. For example, if your engine is running poorly or if you are experiencing decreased fuel efficiency.