A fuel pressure regulator (FPR) is a device that controls the pressure of fuel supplied to the fuel injectors on an engine. The FPR is normally mounted after the fuel rail, ensuring that the fuel rail has priority in fuel flow. The valve in the FPR controls the amount of fuel that is bled from the fuel rail by opening an outlet port, allowing fuel to flow back into the fuel tank. The base pressure is adjusted on all Turbosmart FPRs via the adjustment screw to suit the injectors and fuel pump system. This paragraph aims to provide a comprehensive guide on how to adjust a fuel pressure regulator, covering various aspects, including the function, location, and adjustment process of the FPR.

What You'll Learn

Adjust with the engine running

To adjust a fuel pressure regulator with the engine running, you will need to follow these steps:

Firstly, identify the location of the fuel pressure regulator. In a car with a fuel-injected gasoline engine, it is usually found at the end of the fuel rail. Follow the supply line from the fuel injector to locate the regulator.

Next, ensure that the engine is idling and carefully check for any fuel leaks. This is an important safety precaution as you will be working with fuel.

Now, you can begin to adjust the fuel pressure. The fuel pressure regulator has a small Allen wrench bolt that controls the fuel pressure. Loosen the lock nut with a 5/8" box-end wrench. Then, use a 7/32 Allen wrench to turn the adjustment screw. Turning the screw clockwise will increase the fuel pressure, while turning it anticlockwise will decrease the pressure. Make minor adjustments and do not turn the screw all the way, as this could damage the regulator.

As you adjust the screw, monitor the fuel pressure using a fuel pressure gauge attached to the regulator's pressure port. Alternatively, you can use a fuel pressure sensor to get a digital output. Continue adjusting until you achieve the desired fuel pressure.

Once you have reached the correct pressure, tighten the lock nut with an Allen wrench and shut off the engine.

It is important to note that not all fuel pressure regulators are adjustable. Only racing regulators can be adjusted. Additionally, always refer to the manufacturer's instructions and take the necessary safety precautions when working with fuel.

Replacing Fuel Pressure Regulator in a 1990 Ford Aerostar

You may want to see also

Clockwise to increase pressure

Adjusting a fuel pressure regulator is a straightforward but delicate process. Clockwise adjustments generally increase the pressure, allowing more fuel to flow through the regulator. However, it's important to make these adjustments slowly and incrementally to avoid over-pressurizing the system, which can be dangerous. Here are some detailed, step-by-step instructions to increase pressure safely and effectively:

Prepare the Necessary Tools and Safety Equipment:

- Screwdriver: Use a flat-head or Phillips screwdriver depending on the type of screw head on the adjustment mechanism.

- Wrench: An adjustable wrench may be needed to loosen or tighten nuts or bolts on the regulator or fuel connections.

- Leak Detection Solution: Prepare a soapy water solution or a commercial leak detection solution to check for fuel leaks.

- Safety Gear: Wear protective gloves and safety glasses to safeguard your hands and eyes during the adjustment process. Keep a fire extinguisher nearby as an extra precaution.

Locate the Adjustment Mechanism:

The adjustment mechanism is typically a screw or knob that controls the fuel flow and pressure. It may be located on the side, bottom, or top of the regulator and might be covered by a protective cap.

Turn Off the Fuel Supply:

Before making any adjustments, always shut off the main fuel supply valve to prevent fuel flow. This is an important safety measure to prevent any accidental fuel discharge during the adjustment process.

Inspect the Regulator and System:

Thoroughly inspect the regulator, hoses, and connections for any signs of damage, wear, or leaks. Use the soapy water solution to check for bubbles around the connections, indicating a fuel leak. Do not proceed if any damage or leaks are detected. Replace the affected parts or consult a professional for repairs.

Adjust the Pressure:

Once you've ensured the system is safe, follow these steps:

- Remove the Protective Cap: If your regulator has one, remove the cap to access the adjustment mechanism.

- Adjust Clockwise: Using the appropriate tool, turn the adjustment screw or knob clockwise to increase the fuel pressure. Remember to make small, incremental adjustments.

- Proceed Slowly: Allow time between adjustments to monitor the effect of each change. This gradual approach helps prevent over-pressurizing, ensuring a safe process.

Test and Monitor the System:

After adjusting the pressure, it's crucial to test and observe the system's performance:

- Reopen the Fuel Supply: Slowly turn on the main fuel supply valve to reintroduce fuel into the system.

- Test for Proper Operation: Start the engine and observe its performance. Listen for any unusual sounds that could indicate issues.

- Check for Leaks: Again, use the soapy water solution to check all connections for leaks. No bubbles should form, indicating tight and secure connections.

- Monitor System Performance: Over the next few uses, keep a close eye on the system's performance. Watch for any pressure fluctuations or irregular operation.

Remember, always prioritize safety when adjusting your fuel pressure regulator. Work in a well-ventilated area, wear appropriate protective gear, and consult a professional if you have any doubts or concerns during the process. Regular monitoring and maintenance of your fuel system will ensure its longevity and safe operation.

Ideal Fuel Pressure for Weber 48 IDA Carburetors

You may want to see also

Check the fuel gauge

To check the fuel gauge, you'll need to perform a few tests to ensure the fuel pressure regulator is working correctly.

First, check the fuel pressure with the engine off. Turn the key to activate the fuel pump, and observe the fuel pressure gauge. It should read around 7 PSI. If the pressure is higher or lower, the regulator may need adjustment.

Next, start the engine and re-check the fuel pressure. With the engine running, the fuel pressure should be slightly higher, but not exceed 10 PSI. If the pressure is too high, it may indicate an issue with the regulator or fuel pump.

If the pressure readings are inconsistent or unstable, try adjusting the regulator with the engine running. Make sure to adjust the regulator slowly and observe the gauge to ensure you don't over-correct. Turn the adjustment screw clockwise to increase pressure and counter-clockwise to decrease it.

Additionally, check the float levels in the fuel tank. With the engine off and the fuel pump running, observe the fuel level at the sight plug or sight hole. The fuel should be at a steady level, not fluctuating or leaking out.

If the fuel pressure still doesn't stabilize, there may be a blockage in the system. Check the hoses and lines for any signs of collapse or restriction, and ensure the fuel filter is clean and unobstructed.

By performing these checks, you can ensure the fuel gauge is functioning correctly and identify any issues with the fuel pressure regulator or related components.

Installing a Fuel Pressure Gauge on Cummins: Step-by-Step Guide

You may want to see also

Ensure the fuel rail has priority

Ensuring the fuel rail has priority is a crucial step when adjusting a fuel pressure regulator. Here's a detailed guide on how to achieve this:

Firstly, understand the fuel rail's priority in the fuel system. The fuel rail is responsible for distributing fuel to the injectors, and its pressure directly affects the fuel delivery to the engine. Any obstruction or restriction in the fuel rail can lead to insufficient fuel supply, affecting the engine's performance and fuel efficiency.

To ensure the fuel rail has priority, start by checking the fuel line for any restrictions or blockages. Inspect the fuel line from the fuel tank to the fuel rail for any signs of kinks, leaks, or obstructions. Ensure that the fuel filter is clean and free of debris, as a clogged fuel filter can restrict fuel flow to the rail. Regularly changing the fuel filter as per the manufacturer's recommendation is essential to maintain optimal fuel flow.

Another crucial aspect is verifying the functionality of the fuel pressure regulator. The regulator ensures that the fuel pressure in the rail remains constant and at the correct level. A faulty regulator can lead to either too much or too little fuel pressure, impacting the engine's performance. Have the regulator checked and calibrated by a professional if you suspect any issues.

Additionally, the fuel pump plays a vital role in maintaining fuel rail priority. It ensures an adequate volume of fuel is supplied to the rail. If the fuel pump is weak or faulty, it may not deliver enough fuel, resulting in a lean condition and potential engine damage. Have the fuel pump tested and replaced if necessary to ensure optimal performance and maintain the fuel rail's priority.

Finally, consider the impact of any modifications or upgrades to the fuel system. If you have made changes to the fuel injectors, fuel pump, or engine tuning, it may affect the fuel rail's priority. Ensure that any modifications are compatible and properly calibrated to maintain the correct fuel pressure and flow to the rail. Consult a professional technician for guidance on ensuring the fuel rail has priority in a modified fuel system.

Ideal Fuel Pressure for Oil Burner Furnace Operations

You may want to see also

Use a bypass hose

A bypass-style regulator, also known as a return-style regulator, is designed to bleed off excess pressure in a return line back to the fuel tank. This ensures a reliable operating pressure is supplied to the fuel rail or carburetor. This style of regulator is characterised by a fuel return line from the regulator back to the fuel tank.

The pressure is controlled by a bypass valve that is spring-actuated. As fuel flows through the regulator, the pressure increase in the system forces the spring to open the bypass valve and allow the excess pressure to bleed off. Many aftermarket bypass regulators are adjustable, meaning you can adjust the seat pressure provided by the spring and, in turn, the pressure that the system will see at the carburetor or fuel rail.

Return-style or bypass regulators are recommended for most EFI installations, as well as carburetor installations when a high-pressure pump is used.

Some advantages of a return-style bypass fuel pressure regulator include:

- Fuel is always flowing through the system, helping to keep the fuel temperature within operating conditions.

- It allows high-pressure pumps to operate at maximum efficiency.

- It is generally required for many installations.

However, there are also some disadvantages, including:

The requirement of a return line increases system complexity.

When adjusting a fuel pressure regulator, it is important to ensure accurate and consistent fuel pressure for maximum and consistent high performance.

Checking Fuel Pressure: 2003 F150 Maintenance Guide

You may want to see also

Frequently asked questions

A fuel pressure regulator (FPR) is a device that controls the pressure of the fuel supplied to the fuel injectors on an engine.

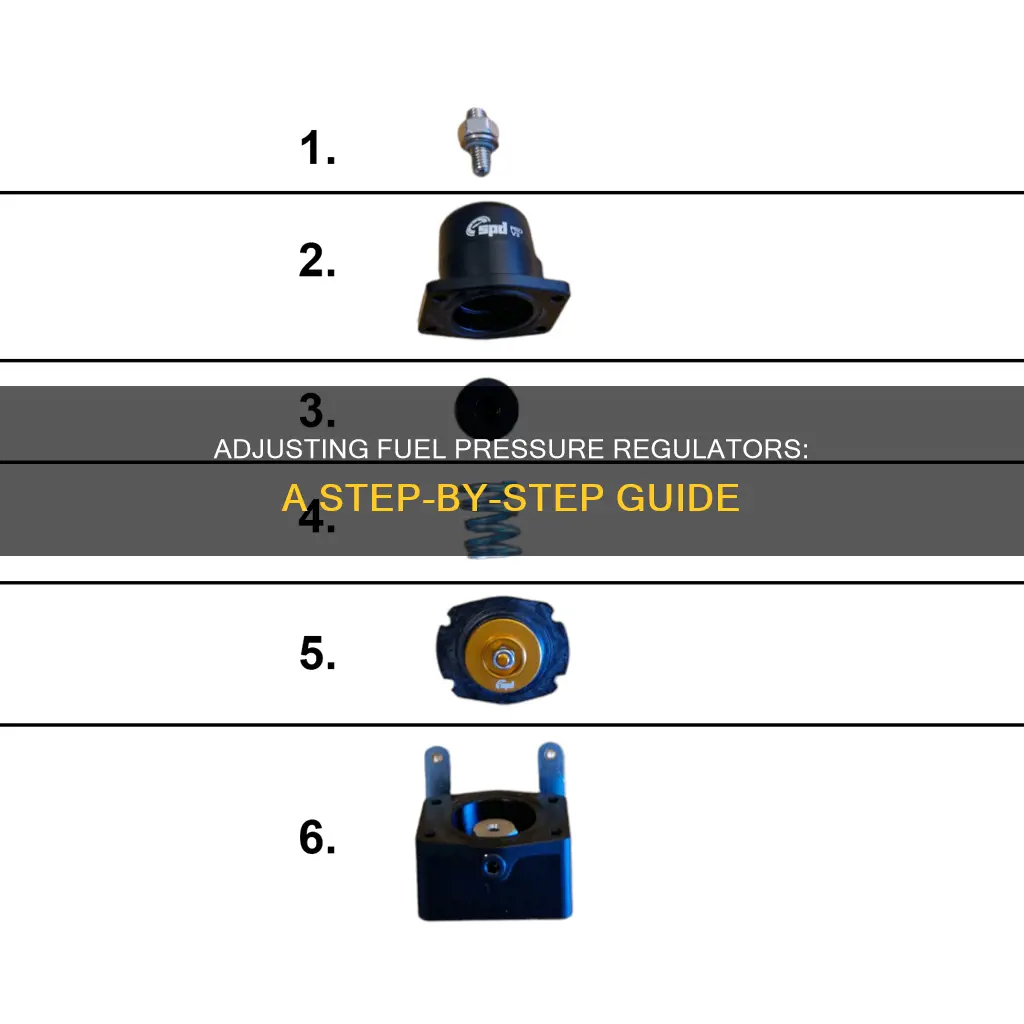

A fuel pressure regulator works by bleeding off a portion of the fuel flow to the injectors from the fuel pump to control the fuel pressure. The fuel is pumped from the fuel tank to the fuel rail by the fuel pump. The FPR is normally mounted after the fuel rail.

The base pressure is adjusted on all Turbosmart FPRs via the adjustment screw to suit the injectors and fuel pump system you are using. The adjustment screw pushes down on a spring that applies a force onto the valve. When the pressure inside the bottom chamber of the FPR exerts a high enough force on the valve, it overcomes the spring force and lifts the valve off its seat. This allows fuel to flow through the outlet port, effectively controlling the fuel pressure in the fuel rail.