Replacing a fuel pump on a 1983 Pontiac Firebird can be a challenging but rewarding task for any car enthusiast. The process involves several steps, including removing the old pump, installing the new one, and ensuring all connections are secure. This guide will provide a detailed, step-by-step approach to help you navigate this process with ease, ensuring your classic car runs smoothly and efficiently.

| Characteristics | Values |

|---|---|

| Vehicle Model | 1983 Pontiac Firebird |

| Fuel Pump Location | Behind the right front wheel well |

| Fuel Pump Type | In-tank or external, depending on the specific model |

| Tools Required | Jack, lug wrench, socket set, new fuel pump, fuel filter, rags, and safety equipment |

| Estimated Time | 2-3 hours (for experienced mechanics) |

| Difficulty Level | Intermediate to Advanced |

| Safety Precautions | Ensure the car is on a level surface, engage the parking brake, and disconnect the battery before starting the process |

| Common Issues | Clogged fuel filter, worn-out pump, or electrical connections |

| Cost of Parts | Varies, but can range from $100 to $300 for the pump and filter |

| Maintenance Tips | Regularly check and replace the fuel filter to prevent pump issues |

What You'll Learn

- Accessing the Pump: Locate and remove the fuel tank and access the pump

- Removing the Old Pump: Disconnect electrical connections and release any fuel pressure

- Installing the New Pump: Align the new pump and secure it with fasteners

- Testing and Filling: Bleed the system and fill with fuel, then test for leaks

- Reassembly and Safety: Reinstall the tank and ensure all connections are secure and safe

Accessing the Pump: Locate and remove the fuel tank and access the pump

To access the fuel pump on an 83 Firebird, you'll need to start by removing the fuel tank. This process requires careful planning and execution to ensure you don't damage any other components. Here's a step-by-step guide:

Locate the Fuel Tank: The fuel tank on a Firebird is typically located behind the rear seat or under the car, depending on the model year and trim. It is usually a metal or plastic tank with a cap on top. Identify the tank's position and take note of any surrounding components that might need to be moved or removed to gain access.

Remove the Fuel Tank: Start by draining the fuel from the tank. Locate the drain valve, which is usually a small opening near the bottom of the tank. Insert a drain pan and open the valve to allow the fuel to drain. Once the tank is empty, locate the mounting bolts that secure the tank to the vehicle. These bolts are often located at the bottom or sides of the tank. Remove these bolts carefully to release the tank. Lift the tank out of the vehicle, being cautious of any fuel lines or hoses connected to it.

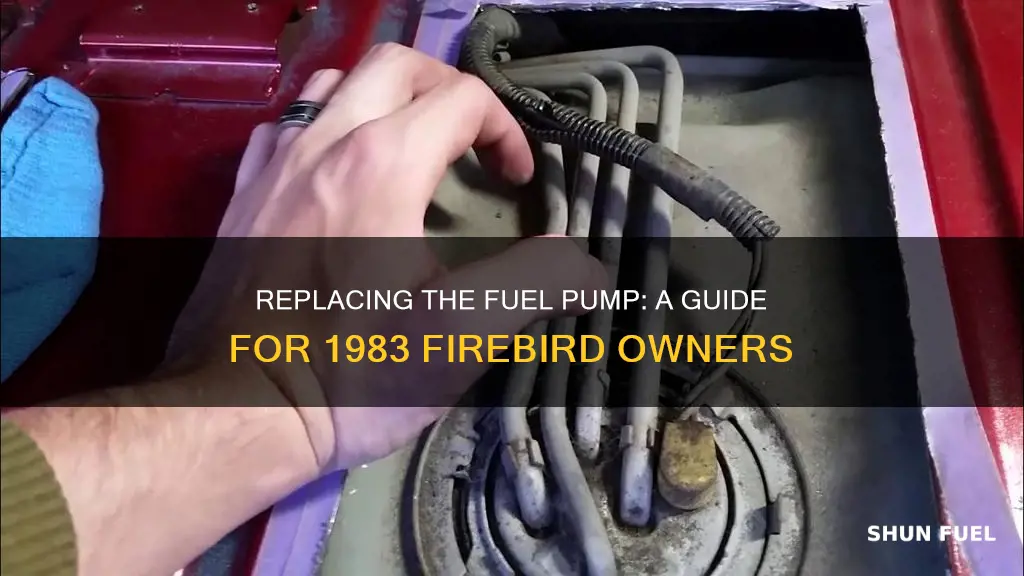

Access the Pump: With the fuel tank removed, you should now have access to the fuel pump. The pump is typically located inside the tank, but on some models, it might be mounted separately. Carefully inspect the area where the pump was previously housed. You might need to remove additional components, such as the fuel lines or a small cover, to fully expose the pump. Take note of the pump's orientation and any electrical connections or sensors attached to it.

Prepare for Pump Removal: Before removing the pump, ensure you have the necessary tools and replacement parts ready. You'll likely need a pump removal tool or a similar device to carefully extract the old pump. Also, have the new pump and any required gaskets or seals readily available. This will make the replacement process smoother and more efficient.

Remember, working on fuel-related components can be hazardous due to the presence of fuel vapor and potential fuel leaks. Always exercise caution, wear appropriate safety gear, and ensure proper ventilation when performing these tasks.

Replacing a Car Fuel Pump: Step-by-Step Guide

You may want to see also

Removing the Old Pump: Disconnect electrical connections and release any fuel pressure

To begin the process of replacing the fuel pump on your 1983 Firebird, you'll need to carefully remove the old pump and prepare for the installation of the new one. Here's a step-by-step guide focusing on the removal process:

Disconnecting Electrical Connections: Start by locating the fuel pump, which is typically found inside the fuel tank or near the engine compartment. Identify the electrical connections that power the pump. These connections are usually in the form of small wires or connectors. Carefully disconnect these wires, ensuring you note their positions for reattachment later. This step is crucial to prevent any electrical issues during the replacement process.

Releasing Fuel Pressure: Before you can remove the old pump, it's essential to release the fuel pressure to avoid any spills or accidents. Locate the fuel pressure relief valve, which is often a small, screw-capped opening on the fuel tank. Use a flathead screwdriver to carefully pry the cap off, allowing the fuel pressure to dissipate. Alternatively, you can disconnect the fuel line from the pump and attach a vacuum pump or a small hose to draw the fuel out of the system. Ensure you have a container ready to catch any fuel that may spill.

Once the fuel pressure is released, you can proceed with removing the old pump. Remember to wear protective gear, such as gloves and safety goggles, to safeguard yourself from any potential fuel splashes. Take your time with this process to ensure a smooth transition to the next steps.

Replacing the Fuel Pump in a 2008 Cadillac Escalade: Step-by-Step Guide

You may want to see also

Installing the New Pump: Align the new pump and secure it with fasteners

To begin the installation of the new fuel pump on your 1983 Firebird, you'll need to carefully align the pump with the existing mounting points. Start by placing the new pump in the same position as the old one, ensuring that the electrical connections are accessible. The pump should be positioned so that the fuel inlet and outlet ports align with the engine's fuel lines. Take your time to get this alignment right, as it will make the rest of the process much easier.

Once aligned, secure the new pump using the appropriate fasteners. Typically, these fasteners are provided with the pump and are designed to fit the existing mounting holes. Use the recommended torque specifications to ensure a secure and tight fit. Over-tightening can damage the pump or the mounting surface, so be cautious and precise with your torque application.

After securing the pump, double-check the alignment and ensure that all fasteners are tight. You may want to use a torque wrench to verify the correct torque value for each fastener. This step is crucial to guarantee that the pump is firmly in place and won't become loose during operation.

With the pump now installed and fastened, you can proceed to the next phase of the replacement process. This careful alignment and secure fastening technique will contribute to a successful fuel pump replacement, ensuring optimal performance and reliability for your classic car. Remember, taking the time to get the initial alignment and fasteners right can save you from potential issues later on.

Replacing the Fuel Filter: A Step-by-Step Guide for Your 200 E-150

You may want to see also

Testing and Filling: Bleed the system and fill with fuel, then test for leaks

Before you begin the process of replacing the fuel pump in your 1983 Firebird, it's crucial to ensure that the fuel system is bled properly to remove any air bubbles and to prevent any potential issues during the installation. Here's a step-by-step guide on how to bleed the system and fill it with fuel:

Bleed the Fuel System:

- Locate the fuel pump and ensure it is disconnected from the vehicle's power source. This is typically done by removing the fuel pump relay or disconnecting the fuel pump wiring harness.

- Identify the fuel lines connected to the pump. There will be two lines: one for fuel intake and one for return.

- Using a suitable bleed valve or a small hose, connect one end to the fuel intake line and the other to a clean container or a fuel catch can.

- Start the engine and allow it to idle. You should hear the fuel pump priming.

- With the engine running, slowly open the bleed valve or hose to allow the fuel to flow into the container. This process will help remove any air from the system.

- Continue this process until the fuel flow stabilizes and there is no more air being expelled. This might take a few minutes.

- Once the bleeding is complete, close the valve and disconnect the hose from the fuel intake line.

Filling with Fuel:

After bleeding the system, it's essential to fill the fuel tank to ensure the pump is fully operational and to prevent any air from re-entering the system.

- Open the fuel tank filler cap and pour in the recommended amount of fuel. You can use any gasoline that meets or exceeds the octane requirements for your vehicle.

- Ensure the fuel level is at the maximum mark on the tank's gauge.

- Close the filler cap securely.

Testing for Leaks:

With the fuel system bled and filled, the next critical step is to test for any leaks to ensure the integrity of the system.

- Inspect all fuel lines and connections for any signs of damage, cracks, or leaks. Pay close attention to the areas where the lines connect to the fuel pump, the engine, and the fuel tank.

- Use a soapy water solution to test for leaks. Spray the soapy water on all connections and observe if any bubbles appear. Bubbles indicate a leak.

- If any leaks are detected, tighten connections or replace damaged lines immediately. Ensure all components are properly secured.

- Once you've confirmed there are no leaks, start the engine and monitor it for any unusual noises or vibrations. The engine should run smoothly without any issues related to the fuel system.

- Test drive the vehicle to ensure the fuel pump is functioning correctly and that there are no unexpected fuel-related problems.

Remember, proper bleeding and filling of the fuel system are essential to ensure a successful fuel pump replacement. Testing for leaks is a critical step to guarantee the safety and performance of your vehicle's fuel system.

Maintenance Matters: Optimal Tank Replacement Schedule for Above-Ground Fuel Storage

You may want to see also

Reassembly and Safety: Reinstall the tank and ensure all connections are secure and safe

After replacing the fuel pump, it's crucial to reassemble the tank and ensure everything is secure and safe to prevent any potential issues. Here's a step-by-step guide to help you through this process:

Reinstalling the Fuel Tank:

- Begin by carefully placing the fuel tank back into its original position. Ensure it is aligned correctly and securely attached to the vehicle's frame. Use the appropriate tools to tighten any mounting brackets or fasteners.

- Reattach all electrical connections that were disconnected during the pump replacement. Double-check that each wire is properly connected to the correct terminal. Make sure the connections are tight and secure to avoid any loose contacts.

- Inspect the fuel lines for any signs of damage or wear. Ensure they are properly routed and securely fastened to the tank and the engine. Tighten any clamps or fittings as needed to maintain a safe and leak-free connection.

Ensuring Safety and Security:

- Test the fuel pump's operation by starting the engine and monitoring for any leaks. Check for any unusual noises or vibrations that could indicate a loose connection or improper reassembly.

- Verify that all fuel lines are functioning correctly and that there is no fuel leakage. Look for any signs of corrosion or damage to the lines and replace them if necessary.

- Inspect the fuel tank for any visible damage, especially around the pump mounting area. Ensure there are no cracks or punctures that could lead to fuel contamination or leaks.

- Finally, take a moment to review the vehicle's manual or online resources specific to your 83 Firebird model. Each vehicle may have unique requirements or recommendations for reassembly and safety checks after major component replacements.

Remember, proper reassembly and safety checks are essential to ensure the vehicle's performance and reliability. By following these steps, you can confidently restore the fuel system's functionality and maintain a safe driving experience.

Replacing the Air-Fuel Ratio Sensor in Your Lexus RX300

You may want to see also