If you're a car enthusiast or a DIY mechanic, you might encounter a common issue with your 1997 Dodge diesel engine: the fuel cut-off relay wiring. This component is crucial for controlling the fuel supply to the engine, and over time, it can become damaged or worn out. In this guide, we'll walk you through the process of replacing the fuel cut-off relay wiring, ensuring your engine runs smoothly and efficiently. We'll provide step-by-step instructions, troubleshooting tips, and essential safety precautions to help you tackle this task with confidence.

| Characteristics | Values |

|---|---|

| Vehicle Model | 1997 Dodge Diesel |

| Relay Location | Under the hood, typically near the engine compartment |

| Relay Type | Fuel Cut-Off Relay |

| Wiring Diagram | Consult the vehicle's service manual or online resources for specific wiring diagrams. |

| Tools Required | Wrenches, screwdrivers, wire cutters/strippers, new relay |

| Steps | 1. Locate the relay. 2. Disconnect the old relay's wiring. 3. Remove the relay from the housing. 4. Install the new relay, ensuring correct polarity. 5. Connect the new relay's wiring. 6. Test the system. |

| Common Issues | Relay failure, wiring faults, fuel pump problems |

| Safety Precautions | Disconnect the battery before working on electrical components. |

| Tips | Refer to the manufacturer's instructions for specific relay specifications. |

What You'll Learn

- Fuel System Basics: Understand the diesel fuel system, including the pump and injectors

- Relay Location: Identify the relay's position under the dashboard or engine compartment

- Wiring Diagram: Obtain a diagram to trace the relay's wiring and connections

- Testing the Relay: Use a multimeter to test the relay for continuity and voltage

- Replacement Steps: Follow a step-by-step guide to replace the relay with a new one

Fuel System Basics: Understand the diesel fuel system, including the pump and injectors

The diesel fuel system is a complex network of components that work together to deliver fuel to the engine for combustion. Understanding its basics is crucial for anyone working on diesel engines, especially when it comes to replacing parts like the fuel cut-off relay. This system is responsible for ensuring the engine receives the right amount of fuel at the right time, which is essential for optimal performance and efficiency.

At the heart of the diesel fuel system is the fuel pump, which is typically located in the fuel tank or near the engine. Its primary function is to draw fuel from the tank and deliver it under pressure to the injectors. Diesel fuel pumps are usually electric and are designed to provide a consistent and precise fuel flow. The pump's operation is controlled by the engine control unit (ECU), which regulates the fuel pressure and ensures it meets the engine's requirements.

Fuel injectors are another critical component of the diesel fuel system. These devices are responsible for spraying the fuel into the engine's cylinders in a precise manner. Each cylinder has one or more injectors, and they are designed to deliver the correct amount of fuel based on the engine's operating conditions. Modern diesel engines use high-pressure common-rail systems, where the fuel is injected directly into the combustion chamber at extremely high pressures, ensuring efficient combustion.

The process begins when the ECU sends a signal to the fuel pump, instructing it to deliver fuel. The pump then pressurizes the fuel and sends it through a series of filters and lines to the injectors. Here, the fuel is atomized and injected into the engine's cylinders. The timing and amount of fuel injected are carefully controlled to optimize power output and fuel efficiency while minimizing emissions.

Understanding the diesel fuel system's intricacies is vital for mechanics and DIY enthusiasts alike. It ensures that any modifications or repairs are made with a clear understanding of how the system works. When replacing the fuel cut-off relay, for instance, one must consider its role in controlling the fuel pump's operation and how it integrates with the overall fuel system. This knowledge helps in making informed decisions and ensuring the engine's performance remains unaffected.

Air-Fuel Sensor: Camry Performance and Economy

You may want to see also

Relay Location: Identify the relay's position under the dashboard or engine compartment

To locate the fuel cut-off relay in a 1997 Dodge diesel, you'll need to access the dashboard or engine compartment, depending on the specific model and year. Here's a step-by-step guide to help you identify the relay's position:

Dashboard Access:

- Start by opening the car's hood and locate the dashboard. You might need to remove some panels or trim pieces to gain access to the dashboard area.

- Look for a small, rectangular or square-shaped box or module. This is often where the fuel cut-off relay is located. It might be labeled as "Fuel Pump Relay" or "Fuel Cut-Off Relay."

- Check the owner's manual for your specific Dodge model to confirm the exact location. Sometimes, relays can be positioned in less obvious places, so a manual will provide valuable insights.

- If you can't find it immediately, consider the following: Relays are often placed near the fuse box or under the steering column for easy access and wiring.

Engine Compartment:

- If the relay is not accessible from the dashboard, you'll need to inspect the engine compartment.

- Locate the engine's wiring harness, which is a bundle of wires that connects various components.

- Follow the wiring harness to find a relay module or a small box-like component. It might be labeled or have a distinct shape.

- Again, refer to the owner's manual for your specific Dodge diesel to ensure you're in the right area.

- Some older Dodge models might have the relay positioned near the battery or under the driver's side dashboard.

Remember, the exact location can vary depending on the specific 1997 Dodge diesel model and any modifications made to the vehicle. Always exercise caution when working under the hood or dashboard to avoid any potential hazards.

Motorcycle Fuel Tips: Post-Carb Replacement, How Much to Add?

You may want to see also

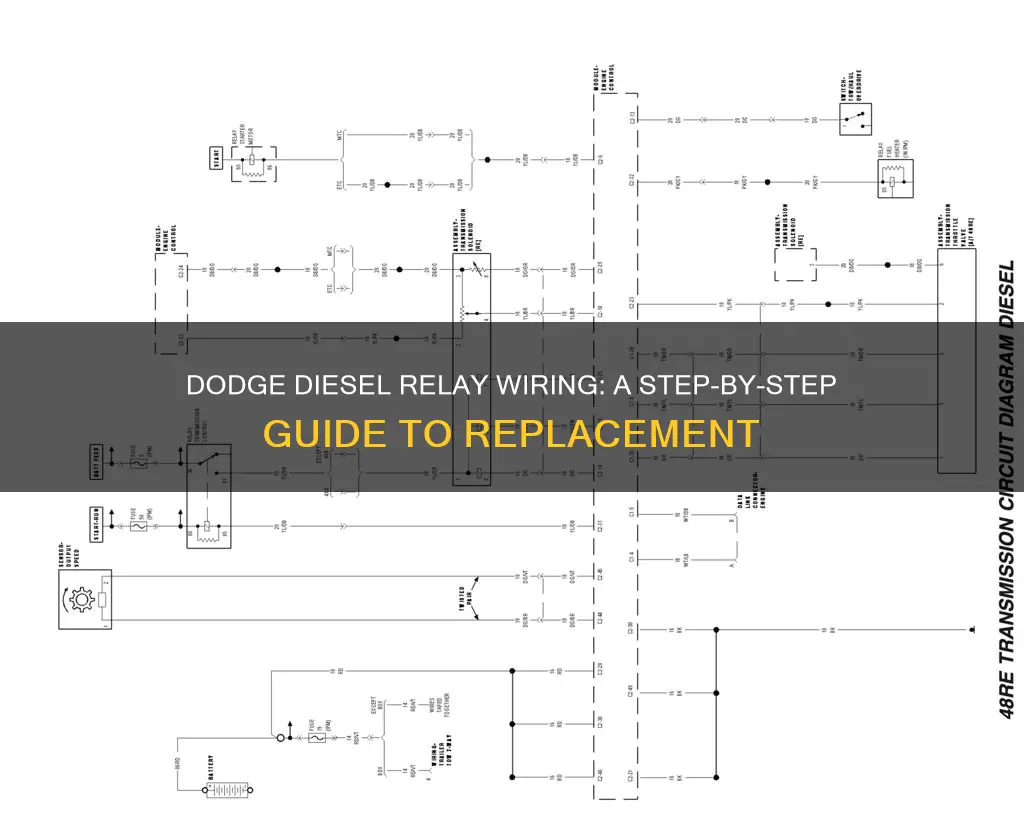

Wiring Diagram: Obtain a diagram to trace the relay's wiring and connections

To effectively replace the fuel cut-off relay in your 1997 Dodge diesel vehicle, obtaining a wiring diagram is crucial. This diagram will provide a visual representation of the relay's wiring and connections, allowing you to trace the path of electricity and identify the components involved. Here's a step-by-step guide on how to approach this:

Start by searching for a reliable source that provides wiring diagrams for your specific Dodge model. You can try visiting online forums or communities dedicated to Dodge diesel engines, as these platforms often have members who share technical information and resources. Alternatively, automotive repair websites or libraries with automotive reference books might offer detailed wiring diagrams for your vehicle. Look for diagrams that specifically show the fuel cut-off relay and its associated wiring harness.

Once you have the wiring diagram, carefully examine it to understand the layout. Identify the relay's location within the engine compartment and locate the wiring harness that connects to it. The diagram should illustrate the various wires, connectors, and terminals associated with the relay. Pay attention to the color-coding or labeling of the wires to ensure correct identification during the replacement process.

Trace the wiring path by following the diagram's lines and connections. Note the starting point, which is typically the battery or the main fuse box, and work your way towards the fuel cut-off relay. Identify any fuses, relays, or sensors that are connected in series or parallel with the relay. Understanding these connections is essential to ensure that you replace the correct components and maintain the integrity of the electrical circuit.

If possible, take a photograph of the diagram for reference during the replacement process. This visual aid will help you locate the relay and its wiring connections more easily when you're working under the hood. Additionally, consider making notes or highlighting specific components on the diagram to create a personalized reference guide.

Remember, working with electrical systems requires caution and precision. If you're unsure about any step, consult a professional mechanic or refer to additional resources to ensure a successful and safe repair.

Replacing the Fuel Line and Filter in a Stihl 026 Chainsaw

You may want to see also

Testing the Relay: Use a multimeter to test the relay for continuity and voltage

When dealing with a fuel cut-off relay in a 1997 Dodge diesel engine, it's crucial to test the relay to ensure it's functioning correctly. This step is often overlooked but is essential to diagnosing and resolving issues related to fuel delivery. Here's a detailed guide on how to test the relay using a multimeter:

Understanding the Relay's Function: Before you begin, it's important to grasp the role of the fuel cut-off relay. This relay is responsible for controlling the flow of electricity to the fuel pump, which in turn activates the fuel injection system. When the engine is running, the relay should allow current to pass, ensuring the fuel pump operates. During engine start-up, the relay is supposed to cut off power to the fuel pump to prevent fuel from reaching the engine before it's ready to ignite.

Gathering the Tools: You'll need a multimeter, which is a versatile tool for electrical testing. Ensure it has the capability to measure both continuity and voltage. Additionally, have a set of screwdrivers or a small tool to access the relay's terminals.

Testing for Continuity: Start by disconnecting the relay from the battery to ensure safety. Locate the relay's terminals, which are typically labeled as 'Input' and 'Output'. Set your multimeter to the continuity setting. Touch the multimeter's probes to the 'Input' terminals. The multimeter should display a low resistance value, indicating continuity. If there's no continuity, it suggests a potential issue with the relay or the wiring connected to it.

Testing for Voltage: After confirming continuity, proceed to test for voltage. Set the multimeter to the voltage setting and touch the probes to the 'Input' terminals. With the engine off, there should be no voltage present at this point. Now, turn the engine on and observe the voltage reading. The voltage should increase, indicating that the relay is functioning correctly and allowing current to flow. If there's no voltage change, it may indicate a faulty relay or wiring issues.

Interpreting Results: If the relay passes both tests, it's likely functioning as intended. However, if there are any issues, further investigation is required. You might need to check the wiring harness for any damage or loose connections. In some cases, a relay may appear functional but still cause starting issues due to internal faults. In such cases, it's advisable to replace the relay to ensure optimal engine performance.

Remember, testing electrical components can be delicate, so exercise caution and ensure you're working in a well-lit, safe environment. If you're unsure about any step, consult a professional mechanic or refer to the Dodge diesel engine manual for specific guidance.

Replacing Optimax Fuel Injectors: A Step-by-Step Guide

You may want to see also

Replacement Steps: Follow a step-by-step guide to replace the relay with a new one

Before you begin the replacement process, ensure you have the necessary tools and a new fuel cut-off relay compatible with your 1997 Dodge diesel engine. Here's a step-by-step guide to help you through the process:

- Locate the Relay: Start by identifying the fuel cut-off relay in your Dodge diesel engine. It is typically located near the engine compartment, often behind a panel or under a cover. Refer to your vehicle's manual or online resources for a precise location.

- Prepare the Vehicle: Park your Dodge on a level surface and engage the parking brake. This step is crucial for your safety and the accuracy of the work.

- Disconnect the Battery: To prevent any accidental electrical discharges, disconnect the negative terminal of the battery. This will ensure that no power is supplied to the relay during the replacement process.

- Remove the Old Relay: Carefully inspect the relay's wiring connections. Loosen the screws or clips holding the old relay in place and gently pull it out of the socket. Take note of the wiring arrangement to ensure proper reconnection later.

- Install the New Relay: Take the new fuel cut-off relay and align it with the socket, ensuring the wiring terminals match the old relay's connections. Secure the new relay in place using the screws or clips. Double-check that all connections are tight and secure.

- Reconnect the Battery: Once the new relay is installed, reconnect the negative battery terminal.

- Test the System: Start the engine and check for any error codes or warning lights. Ensure that the fuel cut-off function is operational by testing the vehicle's performance and responsiveness.

Remember, if you're unsure about any step, it's best to consult a professional mechanic or refer to detailed online tutorials specific to your vehicle model. Safety and proper wiring connections are paramount when working with electrical components.

Chevy Cruise Fuel Injector Replacement: Cost Breakdown and Tips

You may want to see also

Frequently asked questions

Replacing the fuel cut-off relay in your 1997 Dodge diesel engine is a manageable task. First, locate the relay module, often found under the dashboard or in the engine compartment. Carefully inspect the relay and compare it with the diagram in your vehicle's manual to ensure you have the correct part. Then, disconnect the old relay by releasing the clip or screws holding it in place. Take note of the wiring connections and label them for easy reattachment. Purchase a new relay that fits your specific model and engine type. When installing the new relay, ensure proper alignment and secure it with the appropriate fasteners. Double-check the wiring connections and test the relay to ensure it functions correctly before reassembling the vehicle.

Yes, it is possible to repair the wiring issue without replacing the relay. Start by identifying the damaged wiring or connections related to the fuel cut-off relay. Carefully inspect the wiring harness for any signs of damage, corrosion, or loose connections. Clean the terminals and ensure they are free of debris. If any wires are damaged, cut them and replace them with new ones of the same gauge. Reattach the wiring securely and double-check all connections. Test the relay and its functionality after the repair to ensure the issue is resolved.

Several factors can contribute to a faulty fuel cut-off relay in your 1997 Dodge diesel. Electrical issues, such as corroded or damaged wiring, can cause intermittent or complete relay failure. Over time, the relay's internal components may wear out, leading to malfunction. Extreme temperatures or exposure to moisture can also impact the relay's performance. Additionally, if the relay module is located in an area prone to physical damage, it may become faulty. Regular maintenance and inspection of the wiring harness and relay module can help prevent such issues.