The replacement of nuclear fuel rods is a critical aspect of nuclear power plant operations, ensuring the efficient and safe generation of electricity. These fuel rods, which contain uranium or plutonium, are at the heart of the nuclear reactor, undergoing a complex process of fission that produces heat and energy. Over time, the fuel rods become less efficient due to the accumulation of radiation damage, leading to a decrease in power output and an increase in the risk of overheating. The frequency of fuel rod replacement varies depending on several factors, including the type of reactor, the specific design of the fuel, and the operating conditions. Typically, fuel rods are replaced every 12 to 18 months, but this can range from as little as 6 months to several years. Understanding the replacement schedule is essential for maintaining the reliability and safety of nuclear power plants, as it directly impacts the overall performance and longevity of the facility.

What You'll Learn

- Fuel Rod Life Cycle: Nuclear reactors operate fuel rods for 3-4 years before replacement

- Replacement Frequency: Plants replace 1/3 of fuel rods every cycle

- Safety Protocols: Strict procedures ensure safe rod removal and insertion

- Maintenance Challenges: Replacing rods requires specialized equipment and skilled personnel

- Waste Management: Used rods are stored in pools for cooling before disposal

Fuel Rod Life Cycle: Nuclear reactors operate fuel rods for 3-4 years before replacement

The life cycle of nuclear fuel rods is a critical aspect of the operation and maintenance of nuclear reactors. These fuel rods, which are the heart of the reactor, undergo a precise and carefully managed process from the moment they are loaded into the core until they are eventually replaced. This cycle is designed to optimize the efficiency and safety of the reactor while ensuring the production of a steady supply of nuclear energy.

Within the reactor core, fuel rods are arranged in fuel assemblies, which are then loaded into the reactor. These fuel rods are typically made of uranium dioxide (UO2) and are highly enriched, containing a higher concentration of fissile material compared to natural uranium. The enrichment process ensures that the fuel rods have the necessary properties to sustain a chain reaction and generate heat.

During the operational phase, which lasts for approximately 3 to 4 years, the fuel rods undergo a series of transformations. As the reactor operates, the uranium undergoes fission, releasing a tremendous amount of energy. This process gradually reduces the uranium's fissile material, and the fuel rods become less efficient over time. The reactor's control systems carefully monitor this degradation, ensuring that the fuel rods are utilized optimally.

After this operational period, the fuel rods are considered spent and are carefully removed from the reactor. The spent fuel rods are highly radioactive and require specialized handling and storage to ensure the safety of personnel and the environment. The replacement process is a delicate operation, as it involves replacing the entire fuel assembly to maintain the reactor's performance and safety.

The replacement of fuel rods is a critical maintenance task in the nuclear industry. It ensures that the reactor operates at peak efficiency and safety. The timing of replacement is based on the fuel's performance and the accumulation of radiation damage. This process is a well-established procedure, allowing nuclear power plants to maintain a consistent and reliable energy output. The fuel rod life cycle is a testament to the intricate and precise nature of nuclear power generation, where every step is carefully managed to ensure the safe and efficient production of energy.

Fuel Filter Replacement: Essential Tools and Tips

You may want to see also

Replacement Frequency: Plants replace 1/3 of fuel rods every cycle

In the context of nuclear power generation, the replacement frequency of fuel rods is a critical aspect of plant operation and maintenance. Unlike conventional power plants that burn fuel, nuclear reactors use uranium fuel rods to generate heat through nuclear fission. These fuel rods are carefully designed to optimize energy output while minimizing waste. The process of replacing these rods is a delicate balance between ensuring a continuous power supply and maintaining the integrity of the reactor.

The frequency of replacement is a key factor in the overall efficiency and safety of a nuclear power plant. It is determined by the plant's design, the type of reactor, and the specific fuel used. One common practice is to replace a significant portion of the fuel rods during each refueling cycle. This cycle is a planned event where the plant's operations are halted to allow for the replacement of spent fuel and the insertion of new fuel assemblies.

The replacement frequency is often expressed as a fraction or percentage of the total fuel load. For instance, a plant might replace one-third of its fuel rods during each refueling cycle. This approach ensures a steady supply of fresh fuel while also providing an opportunity to inspect and maintain the reactor components. By replacing a substantial portion of the fuel, plants can optimize the burn-up of the remaining fuel, maximizing energy output and minimizing the volume of radioactive waste generated.

This replacement strategy is carefully planned to minimize downtime and ensure the plant's reliability. During the refueling cycle, specialized equipment is used to remove the spent fuel, which has reached the end of its useful life, and insert new fuel rods. This process requires precise coordination to ensure the reactor's safe operation and the efficient management of resources. The replacement frequency is a critical parameter in the plant's maintenance schedule, influencing the overall performance and longevity of the nuclear power facility.

Understanding the replacement frequency is essential for operators and regulators alike. It allows for better planning and management of the plant's resources, ensuring a consistent power output while adhering to safety standards. The practice of replacing a significant fraction of fuel rods during each cycle is a standard procedure in the nuclear industry, contributing to the efficient and safe operation of these power plants.

Replacing the Fuel Pump in Your 2003 Alero: Step-by-Step Guide

You may want to see also

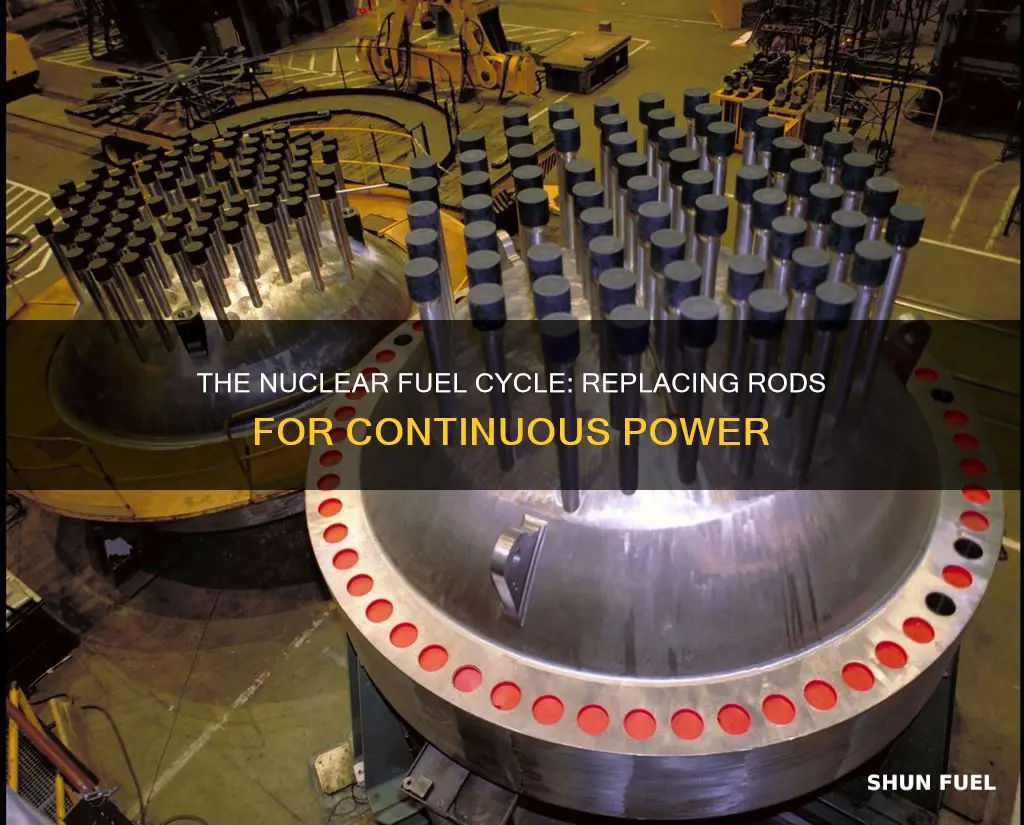

Safety Protocols: Strict procedures ensure safe rod removal and insertion

In the intricate world of nuclear power generation, the safe removal and insertion of fuel rods are critical processes that demand meticulous adherence to strict safety protocols. These protocols are designed to minimize the risks associated with handling highly radioactive materials and ensure the overall safety of the facility and its personnel. The process of replacing nuclear fuel rods is a complex and carefully managed operation, requiring a series of well-defined steps to be executed with precision.

The replacement process begins with a comprehensive assessment of the fuel assembly. Before any removal or insertion takes place, engineers and technicians conduct thorough inspections to evaluate the condition of the fuel rods, including their integrity, radiation levels, and any signs of damage or degradation. This initial step is crucial as it helps identify potential issues and ensures that only suitable rods are selected for replacement. Specialized tools and equipment are used to carefully extract the fuel rods from the assembly, following a sequence that minimizes radiation exposure to workers.

Strict procedures are in place to manage the handling and transportation of the removed fuel rods. These protocols include the use of shielded containers and specialized vehicles to transport the rods to a dedicated storage area or for further processing. All personnel involved in this stage undergo rigorous training to ensure they are equipped with the knowledge and skills to handle the rods safely. This includes understanding the proper use of personal protective equipment (PPE) and implementing controlled access protocols to restrict unauthorized personnel.

When inserting new fuel rods, a series of safety measures are activated. The insertion process is carefully timed and synchronized with the reactor's operational cycles to ensure optimal performance and minimize radiation exposure. Technicians follow detailed step-by-step procedures, including the use of specialized tools and equipment designed to facilitate the insertion while maintaining a safe distance from the highly radioactive environment. This phase also involves rigorous testing and verification to confirm the correct placement and functionality of the new fuel rods.

The entire process of fuel rod replacement is a highly regulated and controlled operation, requiring the coordination of various specialized teams. It is a delicate balance between ensuring the efficient operation of the nuclear reactor and maintaining the highest standards of safety. Regular training programs and simulations are conducted to keep personnel updated on the latest procedures and emergency response protocols, further reinforcing the commitment to safety in this critical aspect of nuclear power generation.

Replacing Fuel Pump in 2003 Miata: Step-by-Step Guide

You may want to see also

Maintenance Challenges: Replacing rods requires specialized equipment and skilled personnel

The process of replacing nuclear fuel rods is a complex and critical aspect of nuclear power plant maintenance, presenting several challenges that require specialized equipment and highly skilled personnel. One of the primary reasons for this is the inherent risks associated with handling radioactive materials. Nuclear fuel rods are highly radioactive and contain dangerous isotopes that can emit ionizing radiation. This radiation can be harmful to both the environment and human health, making it essential to employ strict safety protocols and specialized equipment to mitigate these risks.

Specialized equipment is crucial for the safe and efficient replacement of fuel rods. This includes remote handling systems, which are designed to manipulate the rods without direct human contact. These systems often consist of robotic arms or specialized tools that can grasp, move, and replace the rods while maintaining a safe distance from the radiation source. Remote handling is essential to minimize the exposure of maintenance personnel to harmful radiation. Additionally, the equipment must be designed to handle the extreme conditions within the reactor, including high temperatures and pressure.

Skilled personnel are another critical component of this process. Replacing fuel rods requires a team of highly trained professionals, including nuclear engineers, technicians, and safety officers. These individuals must possess extensive knowledge of nuclear physics, reactor design, and safety protocols. They are responsible for planning and executing the replacement process, ensuring that all procedures are followed precisely to minimize the risk of errors. The team must also be adept at using the specialized equipment, requiring rigorous training and practice to master the techniques involved.

The replacement process itself is intricate and time-consuming. Fuel rods are typically replaced in a controlled manner, with specific sequences and procedures to ensure the safety of the plant and its personnel. This includes carefully removing the old rods, handling them with specialized containers to prevent contamination, and inserting new fuel assemblies while maintaining the integrity of the reactor's core. Each step must be executed with precision to avoid any potential accidents or system malfunctions.

Furthermore, the maintenance schedule for fuel rod replacement is carefully planned and optimized. Nuclear power plants operate under strict regulations, and the frequency of rod replacement depends on various factors, including the type of reactor, fuel design, and operational parameters. Typically, fuel rods are replaced every 12 to 18 months, but this can vary. The timing of replacements is crucial to ensure the reactor's performance and safety, as well as to minimize downtime and maintenance costs.

Replacing the Fuel Sending Unit in Your 2003 Buick Regal

You may want to see also

Waste Management: Used rods are stored in pools for cooling before disposal

The process of managing used nuclear fuel rods is a critical aspect of nuclear power plant operations, ensuring the safety and efficiency of the overall waste management system. After their service in the reactor, these rods undergo a series of steps before they can be considered for disposal. One of the initial and crucial steps in this process is the storage of used fuel rods in water-filled pools, often referred to as spent fuel pools or cooling pools.

These cooling pools are designed to provide a safe and controlled environment for the used fuel rods to cool down. The rods, having been exposed to extreme temperatures during their operation, need to be cooled to a safe level before any further processing or disposal. The water in the pool acts as a heat sink, absorbing the residual heat from the fuel, which is then dissipated into the surrounding environment. This cooling process is essential to prevent overheating and potential damage to the fuel rods and the surrounding infrastructure.

The duration of this cooling period can vary depending on the specific design and requirements of the nuclear power plant. Typically, the used fuel rods are left in the cooling pool for several weeks to a few months. During this time, the heat generated by the rods decreases significantly, allowing for safer handling and transportation. The cooling pools are often designed with multiple layers of safety features, including emergency cooling systems, to ensure the rods remain stable and safe during this critical phase.

Once the cooling process is complete, the used fuel rods are prepared for long-term storage or disposal. This involves a series of intricate processes, including the removal of the rods from the pool, their transportation to a centralized storage facility, and eventually, their secure disposal. The entire waste management process is highly regulated and requires meticulous planning to ensure the safety and environmental protection of the surrounding areas.

In summary, the storage of used nuclear fuel rods in water-filled pools is a vital step in the waste management cycle, providing a safe and controlled environment for cooling and subsequent processing. This method ensures that the fuel rods are handled and managed in a manner that prioritizes safety and environmental sustainability, which is crucial in the context of nuclear power generation and waste management.

Replacing Husqvarna 125B's Fuel Line: Step-by-Step Guide

You may want to see also

Frequently asked questions

The replacement frequency of nuclear fuel rods varies depending on the specific reactor design and operational strategies. Typically, fuel rods are replaced every 12 to 18 months. This replacement cycle is determined by the burn-up of the fuel, which refers to the amount of nuclear fuel that has been used and converted into heat and radiation. During this cycle, spent fuel rods are removed from the reactor and replaced with fresh fuel rods to maintain the reactor's power output and ensure safe operation.

Several factors influence the replacement schedule of fuel rods:

- Burn-up: As mentioned earlier, the burn-up of the fuel is a critical factor. Higher burn-up levels may require more frequent replacements.

- Reactor design: Different reactor designs have varying fuel rod configurations and cooling systems, which can impact the replacement frequency.

- Power output: The desired power output of the reactor may influence the replacement schedule to maintain optimal performance.

- Safety considerations: Regulatory bodies and safety protocols may dictate specific replacement intervals to ensure the safe operation of the nuclear facility.

Yes, advancements in fuel rod technology have led to improvements in performance and longevity. For example, some modern fuel rods are designed to withstand higher burn-up levels, allowing for extended operational periods without replacement. This can result in reduced waste generation and improved overall efficiency. However, these advancements also require careful maintenance and monitoring to ensure the safe and reliable operation of the reactor.

The replacement of fuel rods plays a significant role in nuclear waste management. Spent fuel rods, which are removed from the reactor during the replacement process, contain a significant amount of radioactive material. Proper handling, storage, and disposal of these spent fuels are essential to ensure the safety of the environment and personnel. Advanced waste management techniques, such as reprocessing and long-term storage, are employed to manage and reduce the volume of nuclear waste generated by fuel rod replacements.