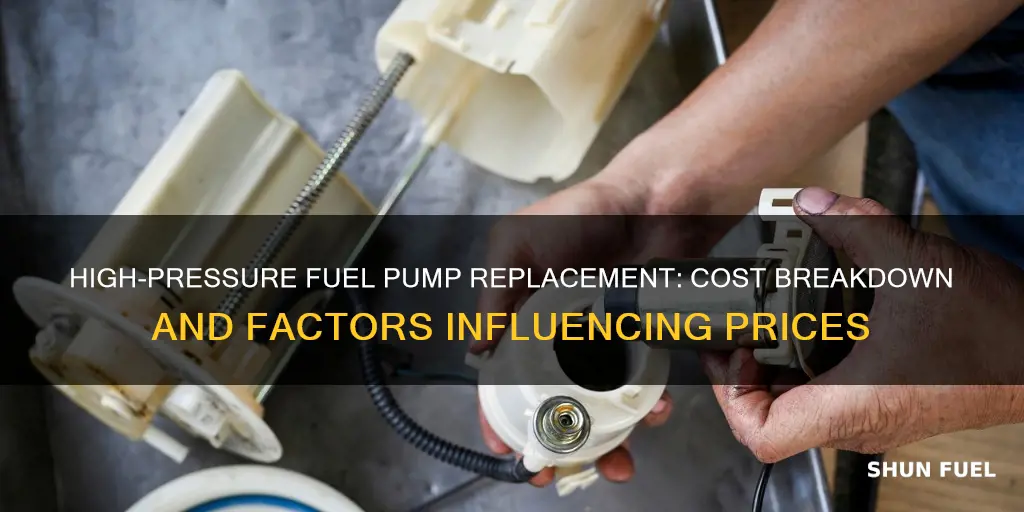

Replacing a high-pressure fuel pump is a crucial repair for vehicles with fuel injection systems, as it ensures optimal engine performance and longevity. The cost of this replacement can vary widely depending on several factors, including the make and model of the vehicle, the specific pump required, and the complexity of the installation process. Understanding these variables is essential for vehicle owners to estimate the financial commitment needed for this repair and to make informed decisions regarding their vehicle's maintenance.

What You'll Learn

- Cost Factors: Labor, parts, vehicle model, and location impact replacement costs

- Symptoms: Engine stalling, hard starts, and reduced power indicate a failing pump

- Diagnosis: Mechanics use diagnostic tools to confirm pump malfunction

- Replacement Process: Involves removing old pump, installing new one, and testing

- Maintenance: Regular checks and timely repairs can prevent pump failure

Cost Factors: Labor, parts, vehicle model, and location impact replacement costs

The cost of replacing a high-pressure fuel pump can vary significantly depending on several factors, and understanding these elements is crucial for anyone facing this automotive repair. Firstly, labor costs play a pivotal role. The complexity of the job and the mechanic's expertise directly influence the price. In some cases, a professional mechanic might charge more for their specialized skills and the time required to disassemble and replace the pump. Conversely, a DIY enthusiast might save on labor costs by performing the task themselves, although this should only be attempted if the individual has the necessary mechanical knowledge and tools.

Parts expenses are another significant contributor to the overall cost. The high-pressure fuel pump itself can range from affordable to expensive, depending on the make and model of the vehicle. Original Equipment Manufacturer (OEM) parts, which are genuine and directly sourced from the car's manufacturer, tend to be more costly but offer the best fit and performance. Aftermarket parts, while often cheaper, may not always be compatible or reliable, potentially leading to further issues.

Vehicle model and year also impact replacement costs. Different car models have unique engine designs and component layouts, which can affect the accessibility and cost of the fuel pump. For instance, a pump for a luxury sedan might be more expensive and challenging to replace compared to a pump in a compact car. Additionally, older vehicles may have less readily available parts, driving up costs.

Location is another critical factor. The price of labor and parts can vary depending on the geographical location. Urban areas with a higher cost of living often have higher labor rates, making the replacement more expensive. In contrast, rural areas might offer more competitive prices due to a lower cost of living and fewer business overheads. Online marketplaces and local mechanic shops can provide quotes, and comparing prices from different sources is advisable to ensure a fair deal.

Lastly, the reputation and experience of the mechanic or repair shop can influence costs. Established, well-known shops might charge more for their services due to brand recognition and the perceived quality of their work. However, this doesn't always guarantee the best value, and it's essential to consider the specific skills and experience required for the job.

Replacing Fuel Injectors in Your Dodge Charger: Step-by-Step Guide

You may want to see also

Symptoms: Engine stalling, hard starts, and reduced power indicate a failing pump

A failing high-pressure fuel pump can lead to a variety of symptoms that are often frustrating for vehicle owners. One of the most common issues is engine stalling, which can occur at any time, even when the car is idling or when you're driving at moderate speeds. This stalling is often accompanied by a lack of power, making it difficult to accelerate or maintain speed. Another symptom is hard starts; the engine may struggle to start, requiring multiple attempts or even refusing to start at all, especially in cold weather. These symptoms are indicative of a pump that is not delivering sufficient fuel pressure to the engine, leading to poor performance and potential stalling.

The reduced power and performance are directly linked to the pump's inability to supply the required fuel volume and pressure. When the pump fails to deliver the necessary fuel, the engine's combustion process is compromised, resulting in a noticeable decrease in power output. This can be especially problematic during acceleration, as the engine may lag or hesitate, making it challenging to maintain or gain speed.

In addition to stalling and hard starts, you might also notice that the engine's performance is inconsistent. It may run smoothly for a while, but then suddenly stall or lose power. This unpredictability can be a significant inconvenience and may lead to further diagnostic challenges. It's important to address these symptoms promptly to prevent further damage to the engine and to ensure the vehicle's reliability.

If you experience any of these symptoms, it is crucial to have the fuel pump inspected and, if necessary, replaced. Delaying the repair can lead to more extensive engine damage, potentially requiring costly repairs. Regular maintenance and prompt attention to these warning signs can help ensure your vehicle's long-term reliability and performance.

Remember, while the cost of replacing a high-pressure fuel pump can vary depending on the make and model of your vehicle, as well as the specific parts required, addressing the issue early on will likely save you from more expensive repairs in the future.

Mastering Chainsaw Maintenance: A Step-by-Step Guide to Replacing Husqvarna Fuel Lines

You may want to see also

Diagnosis: Mechanics use diagnostic tools to confirm pump malfunction

Mechanics employ a variety of diagnostic tools to identify and confirm a malfunctioning high-pressure fuel pump. These tools are essential in pinpointing the exact cause of the issue, ensuring an accurate and efficient repair process. Here's an overview of the diagnostic process:

Code Readers and Scanners: One of the primary tools is a code reader or scanner. When a vehicle's engine is started, it may display error codes related to the fuel system. Mechanics use these scanners to retrieve and interpret these error codes. For instance, a code P0299 might indicate a problem with the fuel pump module. By reading these codes, mechanics can quickly narrow down the potential causes and confirm if the fuel pump is indeed the culprit.

Engine Sensors and Performance Testing: Diagnostic tools often include various sensors and performance testers. These devices can measure engine parameters such as fuel pressure, mass airflow, and cylinder pressure. By connecting these tools to the vehicle's diagnostic port, mechanics can monitor the engine's performance in real-time. If the fuel pump is not functioning correctly, these tests will likely reveal abnormal readings, such as low fuel pressure or irregular fuel flow.

Visual Inspection and Listen for Operation: A simple yet effective method is a visual inspection and listening test. Mechanics will inspect the fuel pump for any visible signs of damage or wear, such as cracks or leaks. They might also listen to the pump's operation while the engine is running. A healthy fuel pump should produce a steady, rhythmic sound. If it's silent or makes unusual noises, it could indicate a malfunction.

Fuel Pressure Gauge: A fuel pressure gauge is a crucial tool for this diagnosis. Mechanics connect this gauge to the fuel system and measure the pressure. A healthy high-pressure fuel pump should deliver a specific range of fuel pressure. If the pressure is significantly lower or higher than the expected range, it confirms the pump's malfunction. This method provides a direct measurement, leaving little room for doubt.

By utilizing these diagnostic tools and techniques, mechanics can accurately identify and confirm a high-pressure fuel pump malfunction. This process ensures that the repair or replacement is performed correctly, saving time and resources for both the mechanic and the vehicle owner.

Fuel Tank Swap: Uncovering Hidden Water Leaks in Your Trunk

You may want to see also

Replacement Process: Involves removing old pump, installing new one, and testing

The process of replacing a high-pressure fuel pump involves a series of steps that require careful attention to detail and a systematic approach. Here's a detailed breakdown of the replacement process:

Removing the Old Pump: Begin by locating the high-pressure fuel pump, which is typically positioned near the engine's fuel rail. This pump is responsible for delivering fuel at high pressure to the injectors. Start by disconnecting the electrical connections and fuel lines attached to the pump. Carefully remove any screws or fasteners that secure the pump in place. Lift the pump out of the engine compartment, ensuring you have a clear view of the surrounding components. Take note of the pump's orientation and any unique features, as this will aid in the installation of the new pump.

Installing the New Pump: With the old pump removed, it's time to install the new one. Carefully align the new pump with the mounting points, ensuring it is positioned correctly. Secure the pump using the appropriate screws or fasteners, following the manufacturer's specifications. Reattach the fuel lines and electrical connections, double-checking for any tightness or proper connections. It is crucial to ensure that all components are securely in place to prevent any potential leaks or electrical issues.

Testing and Verification: After the installation, it's essential to test the new pump to ensure it functions correctly. Start the engine and monitor for any unusual noises or vibrations. Check for proper fuel pressure using a gauge to confirm that the pump is delivering the required pressure. Verify that the fuel injectors are receiving the correct amount of fuel by observing their operation during engine startup and idling. If everything functions as expected, you've successfully replaced the high-pressure fuel pump. However, if any issues arise, it may indicate a need for further investigation or adjustment.

Remember, this process requires a certain level of mechanical skill and knowledge of engine components. If you're unsure about any step, it's advisable to consult a professional mechanic or refer to a detailed repair manual specific to your vehicle's make and model. Properly replacing a high-pressure fuel pump is crucial for maintaining optimal engine performance and fuel efficiency.

Mechanical Fuel Pump Swap: Electric or Not? Exploring the Options

You may want to see also

Maintenance: Regular checks and timely repairs can prevent pump failure

Regular maintenance and proactive care are essential to ensure the longevity and optimal performance of your high-pressure fuel pump. By implementing a routine check-up schedule, you can identify potential issues early on and take preventive measures to avoid costly and inconvenient pump failures. This is particularly crucial for vehicles that rely heavily on fuel efficiency and performance, as pump malfunctions can lead to reduced power, poor fuel economy, and even engine stalls.

The key to preventing pump failure lies in understanding the importance of regular inspections. Over time, fuel pumps can experience wear and tear due to the harsh conditions they operate in. Debris, contaminants, and fuel degradation can also impact pump performance. By conducting routine checks, you can inspect the pump for any signs of damage, corrosion, or internal wear. Look for leaks, check the pump's electrical connections for corrosion or damage, and ensure that all components are securely attached. It is also beneficial to inspect the fuel lines for any cracks or signs of deterioration, as these can lead to fuel leaks and potential pump failure.

Timely repairs are just as vital as regular maintenance. If you notice any issues during your inspections, it's crucial to address them promptly. For example, if you detect a slight leak in the fuel lines, have the affected section replaced immediately to prevent further damage. Similarly, if the pump shows signs of excessive noise or reduced performance, it may indicate internal wear, and a professional mechanic should be consulted to assess and repair the pump. Delaying repairs can lead to more extensive damage, making the pump replacement process more complex and expensive.

In addition to visual inspections, it's recommended to monitor the fuel pump's performance regularly. You can do this by checking the engine's behavior during acceleration and deceleration. A failing pump may result in delayed fuel delivery, causing the engine to hesitate or stall during acceleration. Conversely, during deceleration, a failing pump might lead to excessive fuel flow, causing the engine to surge or stall. These symptoms can provide valuable clues to potential pump issues, allowing for early intervention.

By adhering to a strict maintenance schedule and addressing any concerns promptly, you can significantly reduce the likelihood of high-pressure fuel pump failure. Regular checks and timely repairs are cost-effective measures that not only save you money in the long run but also ensure your vehicle's reliability and performance. Remember, prevention is always better than cure, and when it comes to your fuel pump, staying proactive can make all the difference.

Hydrogen Fuel Cells: The Next-Gen Energy Storage Solution?

You may want to see also

Frequently asked questions

The cost of replacing a high-pressure fuel pump can vary widely depending on several factors. On average, you can expect to pay anywhere between $200 to $800 or more. The price range is influenced by the make and model of your vehicle, the complexity of the replacement process, and whether you choose to do it yourself or have a professional mechanic handle the job.

Yes, several factors can impact the overall cost. Firstly, the make and model of your car play a significant role, as different vehicles have varying fuel pump systems and parts. Secondly, the location of the fuel pump (whether it's in the tank or inline) can affect the labor involved in removal and installation. Additionally, the availability of the specific pump part can influence the price, as some may be more readily available than others.

Replacing a high-pressure fuel pump can be a complex task, especially if it's located deep within the fuel tank. It requires specialized tools and knowledge of the vehicle's fuel system. While some experienced DIY enthusiasts might attempt it, many opt for professional help to ensure a proper and safe installation. If you choose to go the DIY route, be prepared to invest time and effort into learning the process and sourcing the correct parts.

There are several indicators that your high-pressure fuel pump may be failing or in need of replacement. These include reduced engine performance, difficulty starting the engine, erratic or hard starts, and the presence of fuel-related error codes in the vehicle's computer system. If you notice any of these symptoms, it's advisable to have the pump inspected by a professional to determine if replacement is necessary.

Yes, there are a few strategies to consider. Firstly, research and compare prices for the fuel pump part to find the best deal. You can often save money by purchasing from an aftermarket supplier instead of the dealership. Additionally, if you're comfortable with DIY, consider learning the replacement process to save on labor costs. However, always ensure you have the necessary skills and tools to avoid any potential issues.