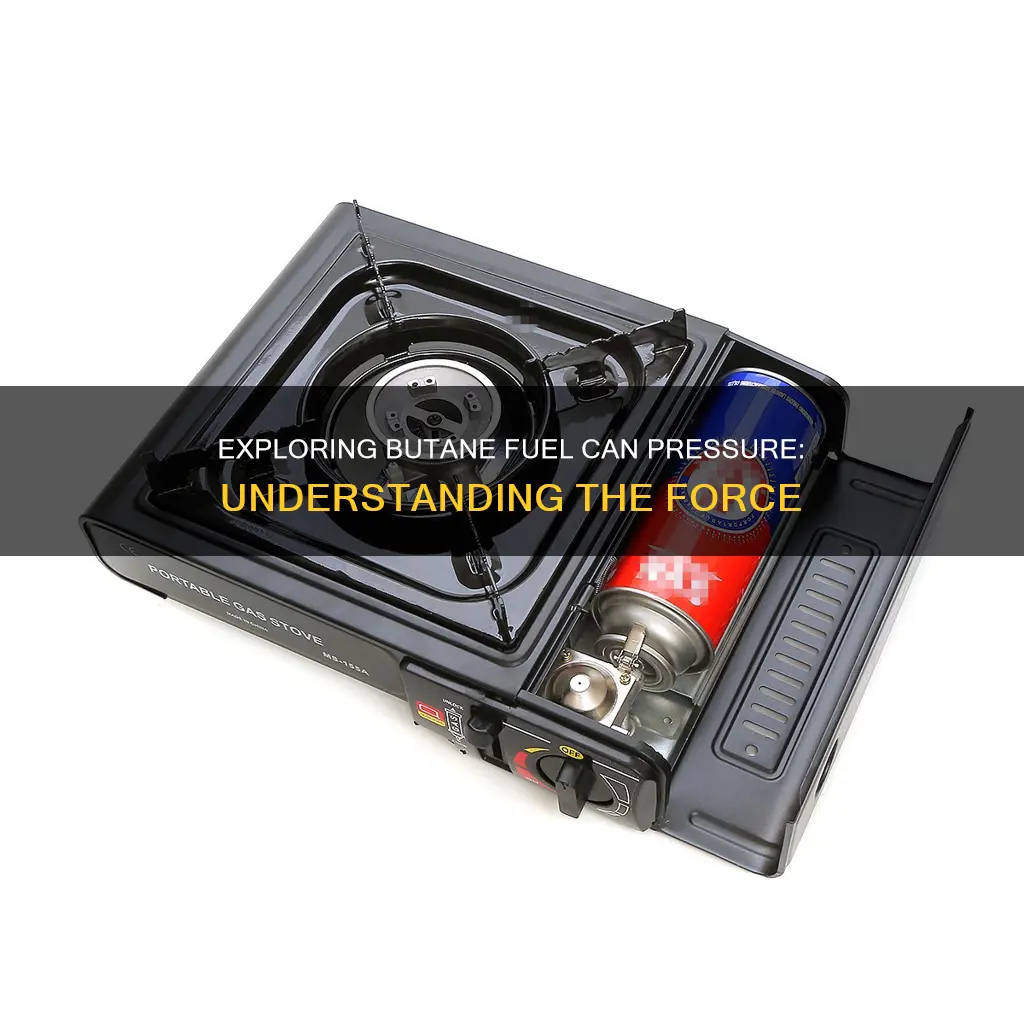

Butane is a highly flammable gas that is commonly used as a fuel source for cooking, camping, and lighting cigarettes and cigars. It is typically stored in pressurised containers as a liquid, which quickly vaporises at room temperature. The pressure inside a butane canister can vary depending on several factors, including temperature, canister design, and application requirements. At room temperature, the vapour pressure of butane is around 2 to 2.5 atmospheres or 30 to 36 psi, but it can range from tens to hundreds of psi depending on the temperature. Understanding the internal pressure of a butane canister is crucial for safety and optimal usage, as high pressure can pose safety risks such as gas leaks or explosions.

What You'll Learn

Butane is stored as a liquid in canisters

Butane is a highly flammable gas that quickly vaporises at room temperature and pressure. It is stored as a liquid in canisters under high pressure. The pressure inside a butane canister can vary based on factors such as temperature, canister design, and specific application requirements. The standard supply pressure of gas exiting the canister is typically regulated to 28 mbar, while the internal pressure of the canister is much higher and can range from tens to hundreds of psi (pounds per square inch). For example, at room temperature (approximately 25°C or 77°F), the vapor pressure of butane is around 2 to 2.5 atmospheres or 30 to 36 psi.

The high internal pressure of butane in canisters is a crucial safety consideration. If exposed to high temperatures, the pressure inside the canister can increase dramatically, posing a significant safety risk. This is due to the direct relationship between temperature and pressure when the volume and amount of gas are constant, as described by the Ideal Gas Law (PV=nRT). Therefore, it is essential to follow safety guidelines and manufacturer specifications when using or storing butane canisters.

The liquid form of butane in canisters undergoes vaporisation to produce gaseous butane for use in appliances. The internal pressure of the canister is essentially the vapor pressure of liquid butane at a given temperature. The vapor pressure is the pressure exerted by the gas phase of a liquid in equilibrium with its liquid phase. This vapor pressure can vary depending on factors such as temperature and purity.

The distinction between internal pressure and standard supply pressure is important. The internal pressure is the pressure inside the canister before any regulation occurs, while the standard supply pressure is the regulated pressure at which the gas is delivered to appliances. This regulation is necessary to decrease the pressure to safe and manageable levels for appliances and tools designed to operate at specific pressure levels. Without proper regulation, the high internal pressure of butane in canisters could pose safety risks, such as gas leaks or explosions.

Fuel Pressure Optimization for CJ7 Performance

You may want to see also

The pressure inside a butane canister can vary

Altitude also plays a role in the internal pressure of a butane canister, but its effect is generally minor compared to temperature changes. At higher altitudes, the atmospheric pressure is lower, resulting in a greater differential pressure between the internal canister pressure and external atmospheric pressure. However, the absolute internal pressure of the butane remains relatively constant unless the temperature changes. As a result, a butane canister may empty more quickly at higher altitudes but is not significantly more likely to rupture or fail.

The design of the canister can also impact the internal pressure. Different canisters may be rated for different internal pressures, with some high-performance canisters designed to withstand higher pressures and constructed with thicker walls or specialized materials. Additionally, canister design may include built-in pressure regulators or safety release valves to prevent over-pressurization.

It is important to note that the standard supply pressure of 28 mbar is typically the regulated pressure at which the gas exits the canister when connected to an appropriate regulator. This pressure is safe for appliances and tools designed to operate at that level. However, the internal pressure of the canister can be much higher, and it is crucial to understand this difference to ensure safe usage and optimal operation of connected appliances.

Furthermore, the density of butane is highly dependent on temperature and pressure. For instance, the density of liquid butane can vary between 571.8±1 kg/m3 and 625.5±0.7 kg/m3 under different pressure and temperature conditions.

Testing Fuel Pressure: 1998 Cobra Maintenance Guide

You may want to see also

Butane can be dangerous if not used correctly

Butane is a powerful and popular fuel source used worldwide. It is generally safe when used correctly, but it can pose serious risks if misused. The pressure inside a butane canister can vary depending on factors such as temperature, canister design, and application requirements. The standard supply pressure of 28 mbar is regulated to ensure safe usage, but the internal pressure can be much higher, ranging from tens to hundreds of psi.

One of the main dangers of butane is its high flammability. Butane is a highly flammable gas, and when compressed into canisters, it becomes even more pressurised and flammable. Improper storage of butane canisters can lead to explosions. Therefore, it is crucial to store butane canisters in a cool, well-ventilated area, away from direct sunlight and other flammable materials. Keeping the canisters upright and secure is also essential.

Additionally, butane can be harmful to human health if inhaled or exposed to the skin and eyes. Inhaling butane can cause short-term effects such as dizziness, drowsiness, fluctuating blood pressure, and even death. Prolonged exposure can lead to changes in bone marrow and potential brain damage. Butane is colourless and odourless, so detecting a leak can be challenging. However, butane gas canisters contain sulfur compounds that produce an unpleasant smell, aiding in early detection and evacuation.

When butane comes into direct contact with the skin or eyes, it can cause frostbite or freeze burns. It is important to rinse the affected area with water immediately and seek medical advice.

To ensure safe usage of butane, it is imperative to follow the manufacturer's guidelines and specifications. Using butane canisters only as directed and understanding the internal pressure and safety measures are crucial to mitigate potential dangers.

Fuel Pressure Regulators: Holding Pressure or Not?

You may want to see also

Butane is highly flammable

Butane is a highly flammable gas that poses a significant safety risk. It is a hydrocarbon and an alkane with the formula C4H10. It exists as two isomers, n-butane (CH3CH2CH2CH3) and iso-butane ((CH3)3CH). Both forms of butane are highly flammable, colourless, odourless, and easily liquefied. Butane gas can cause explosions in poorly ventilated areas if leaks go unnoticed and are ignited by a spark or flame.

The pressure inside a butane canister can vary depending on factors such as temperature, with higher temperatures leading to a higher internal pressure. The internal pressure of a butane canister is crucial to understand for safe operation. It can be much higher than the standard supply pressure, which is typically 28 mbar when connected to a regulator. At room temperature, the vapor pressure of butane is around 2 to 2.5 atmospheres or 30 to 36 psi, which is significantly higher than the standard supply pressure.

Butane is commonly used as a fuel for cigarette lighters, portable stoves, and as a propellant in aerosol sprays. It is also used as a heating fuel, a refrigerant, and in the manufacture of various products. When used as fuel, butane is often mixed with mercaptans to give it an offensive smell, making it easier to detect leaks. While butane itself is not toxic, the contaminants in commercially available butane, such as hydrogen sulfide and mercaptans, can be harmful at high levels.

The inhalation of butane can lead to serious health issues, including euphoria, drowsiness, unconsciousness, asphyxia, cardiac arrhythmia, blood pressure fluctuations, and temporary memory loss. Butane abuse can result in "sudden sniffing death" syndrome, which occurs due to cardiac arrhythmia or cardiac arrest if the person experiences stress or engages in heavy exercise during or shortly after inhalation. It is important to follow safety guidelines and manufacturer specifications when using or storing butane to mitigate the risks associated with its high flammability and potential health hazards.

Understanding Fuel Rail Pressure in X15 Engines

You may want to see also

Butane is used in a variety of applications

The pressure inside a butane gas canister varies based on factors such as temperature, canister design, and specific application requirements. The standard supply pressure is typically 28 mbar, which is the regulated pressure at which the gas exits the canister when connected to a regulator. Inside the canister, the pressure can be significantly higher, ranging from tens to hundreds of psi, depending on the temperature. At room temperature, the vapor pressure of butane is around 2 to 2.5 atmospheres or 30 to 36 psi.

Butane is an organic chemical compound with a variety of applications across different industries. Here are some of its uses:

- Fuel and Energy: Butane is commonly used as a fuel for cooking, barbecues, camping stoves, and lighters. It is also used as a petrol additive to increase volatility and improve engine performance during winter. Additionally, it serves as a feedstock for the production of synthetic petrol and is an essential component in gasoline.

- Refrigeration and Cooling: Pure forms of butane, especially isobutane, are used as refrigerants and have largely replaced ozone-depleting halomethanes in refrigerators, freezers, and air conditioning systems. Butane is particularly suitable for small, portable camping refrigerators.

- Aerosol Propellant: Butane is used as a propellant in aerosol products such as deodorants, hairsprays, air fresheners, and spray paints. It helps dispense the product from the container in a controlled manner.

- Food Industry: Butane plays a role in the production of vegetable oils and is involved in the formation of aqueous emulsions in aerosols, enabling the creation of spray oils for greasing baking trays.

- Chemical Industry: In the chemical industry, butane is used as a solvent, coolant, and reactant in various syntheses and processes. It also serves as a carrier gas for other chemicals.

- Fragrance Extraction: Butane is used as a solvent for fragrance extraction, particularly in the perfume industry.

- Industrial Extraction: Purified butane is employed as a solvent in the industrial extraction of cannabis oils.

Water in Gas: Low Fuel Pressure Culprit?

You may want to see also

Frequently asked questions

The pressure in a can of butane fuel can vary depending on factors such as temperature, canister design, and specific application requirements. The internal pressure of a butane canister is typically higher than the regulated supply pressure of 28 mbar, ranging from tens to hundreds of psi. At room temperature, the vapor pressure of butane is around 2 to 2.5 atmospheres or 30 to 36 psi.

The primary factors that influence the pressure inside a butane gas canister are temperature, altitude, and canister design. Temperature changes have a significant impact on the internal pressure, with an increase in temperature leading to a higher vapor pressure and internal canister pressure. Altitude also affects pressure, as the differential pressure between the canister and external atmospheric pressure is greater at higher altitudes.

The internal pressure of a butane canister is typically much higher than the standard supply pressure of 28 mbar. This underscores the importance of using a regulator to decrease the pressure to safe and manageable levels for appliances and tools.

Understanding the internal pressure of a butane canister is crucial for both safety and effective usage. The high internal pressure can pose safety risks, such as gas leaks or explosions, if not properly regulated. Additionally, it ensures optimal operation of connected appliances and helps with troubleshooting.

Temperature has a direct impact on the internal pressure of a butane canister. As temperature increases, the vapor pressure of liquid butane increases, leading to a higher internal canister pressure. Conversely, a decrease in temperature will lower the internal pressure, which may affect the performance of devices that rely on a specific supply pressure.