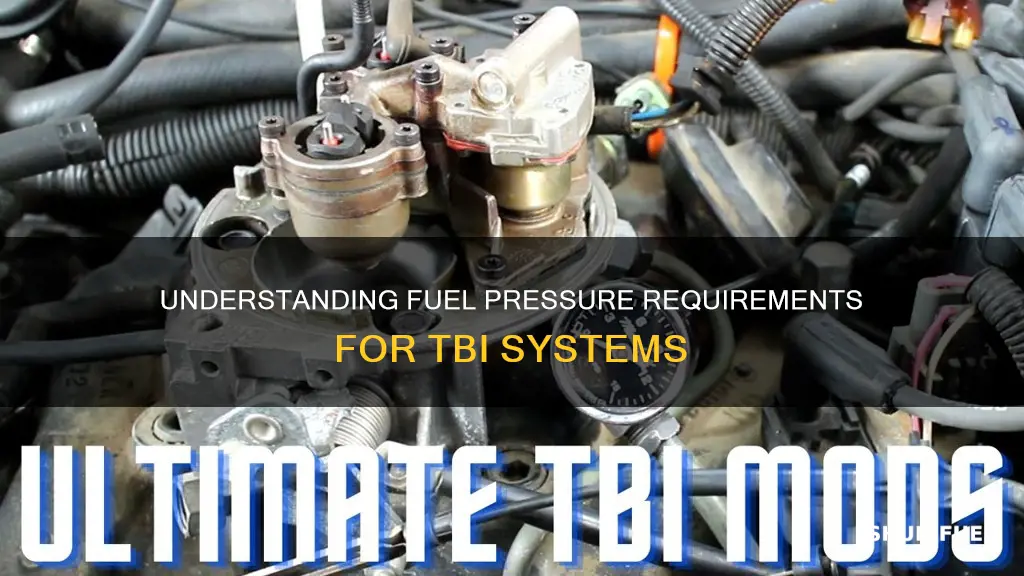

The fuel pressure required for a TBI system depends on the make and model of the vehicle. For instance, a Chevy TBI V-8 engine typically requires between 11 and 13 psi of fuel pressure, while a TBI 350 engine may require up to 15 psi. It's important to note that fuel pressure that is too high can cause issues such as bogging down the motor or sending the computer into limp mode. Additionally, the fuel pump and regulator play a crucial role in maintaining the correct fuel pressure, and choosing the wrong components can lead to problems.

What You'll Learn

TBI fuel pressure is typically between 9 and 15 psi

Throttle Body Injection (TBI) fuel pressure is typically between 9 and 15 psi. TBI systems normally operate around 9 psi but can be increased to 12-13 psi. Going much higher than that can cause the injectors to lock. The stock TBI pump is between 63 and 67 psi, but TBI fuel pressure is typically maintained at around 13 psi, with the excess fuel returned to the tank.

TBI fuel pressure can be increased to improve engine performance. A 1-psi change in fuel pressure can result in roughly a 4% increase in fuel flow, which can lead to an additional 8-10 hp. Adjustable fuel pressure regulators can be purchased to increase fuel pressure, but stock pumps generally cannot generate more than 14-15 psi.

It is important to note that raising fuel pressure increases fuel delivery across the entire engine operating range. While additional fuel is not needed at part throttle, it can be beneficial at wide-open throttle, increasing fuel flow and power.

When adjusting fuel pressure, it is recommended to test any changes with a wide-open throttle (WOT) acceleration run to ensure that the adjustments have the desired effect.

How Fuel Pressure is Generated in Vehicles

You may want to see also

Fuel pressure that is too high can cause the injectors to lock

Fuel injectors are an important component of an engine's fuel system, and maintaining the correct fuel pressure is crucial for their optimal function. Too much fuel pressure can lead to adverse effects, with one of the most significant consequences being the potential locking of the injectors.

In the context of a TBI (Throttle Body Injection) system, the fuel pressure specifications are particularly important to adhere to. TBI systems typically operate within a fuel pressure range of 9-14 psi, with the ability to be adjusted up to 12-13 psi. However, it is crucial not to exceed this upper limit, as doing so can lead to injector locking.

Injector locking occurs when the fuel pressure becomes excessively high, causing the injectors to become stuck in a closed or partially closed position. This prevents the injectors from opening properly, disrupting the precise delivery of fuel to the engine. As a result, the engine may receive an insufficient amount of fuel, leading to poor performance or even stalling.

The risks associated with high fuel pressure extend beyond injector locking. Excessive fuel pressure can also result in an overly rich fuel mixture, causing the engine to produce black smoke and run inefficiently. Additionally, the increased pressure can place unnecessary stress on the fuel pump and other components, potentially leading to premature wear or failure.

To prevent these issues, it is essential to maintain the recommended fuel pressure for your specific TBI system. Refer to the manufacturer's specifications and consult with experts or reliable sources to ensure your fuel pressure settings are appropriate. Regular maintenance and monitoring of fuel pressure can help identify any deviations from the optimal range, allowing for prompt adjustments and reducing the likelihood of injector locking or other fuel system issues.

Relieving Fuel Pressure: Safe DIY Methods Without a Gauge

You may want to see also

A stock TBI injector can handle up to 30 psi

TBI systems normally operate around 9 psi but can be adjusted up to 12-13 psi. Going much higher than that risks locking the injectors. The stock TBI injector can handle up to 30 psi, but the operating pressure is usually lower, around 11-14 psi.

It's important to note that fuel pressure is not the only factor affecting engine performance. The size of the throttle body, the efficiency of the fuel injectors, and the engine's breathing restrictions all play a role in the overall performance of a TBI-equipped vehicle.

To increase the fuel flow, an adjustable fuel pressure regulator can be installed. This allows you to fine-tune the fuel pressure to achieve the desired performance. However, it's important not to exceed the limitations of the stock pump, which typically maxes out at 14-15 psi.

Additionally, raising the fuel pressure increases fuel delivery across the entire engine operating range. While this can provide benefits at wide-open throttle, it may result in an overly rich mixture at part throttle, which can be corrected by the oxygen sensor and the computer adjusting the injector pulse width.

In conclusion, while a stock TBI injector can technically handle up to 30 psi, it is important to consider the overall engine setup and performance goals when determining the optimal fuel pressure. Fine-tuning and adjustments to other components may be necessary to achieve the desired results.

Replacing LQ4 Fuel Pressure Regulator: Step-by-Step Guide

You may want to see also

A fuel pressure regulator can be used to increase fuel pressure

The fuel pressure for a TBI system typically operates at around 9 psi but can be increased to 12-13 psi. Going higher than that can cause the injectors to lock. A fuel pressure regulator can be used to increase fuel pressure and is a must-have item for any EFI system. It maintains a steady fuel supply by controlling the bypass valve, which opens and closes to adjust for steady fuel delivery. The regulator ensures that the fuel rail can build up enough pressure to support the injectors and prevents too much fuel from entering the injectors, which can cause them to fail.

The fuel pressure regulator is typically installed between the fuel pump and the carburetor or throttle body but can also be at the end of a fuel injection rail. It controls the amount of fuel that is bled from the fuel rail by opening an outlet port, allowing fuel to flow back into the fuel tank. This ensures that the fuel rail has priority in fuel flow. The regulator also includes a boost or vacuum reference, which provides additional pressure as vacuum drops or boost increases, preventing fuel starvation under heavier acceleration.

The base pressure of the regulator can be adjusted to suit the injectors and fuel pump system being used. This is done through an adjustment screw that pushes down on a spring, which applies force onto the valve. When the pressure inside the bottom chamber of the regulator becomes high enough, it lifts the valve off its seat, allowing fuel to flow through the outlet port and controlling the fuel pressure in the fuel rail.

It is important to note that the target power level will determine the amount of fuel needed and the size of the regulator required. A larger regulator can handle more flow and higher pressure. Additionally, the type of fuel being used should be considered when choosing a regulator, as some regulators are designed to handle specific types of fuel, such as race fuel or alcohol.

Fuel Pressure Mystery: Why the Rise After Shutting Down?

You may want to see also

Fuel pressure can be measured with a fuel pressure gauge

Fuel pressure in a TBI system typically operates at around 9 psi, but can be increased to 12-14 psi. Going much higher than this can cause the injectors to lock. The stock pump for a TBI 350, for example, is between 63-67 psi, but the injectors can only handle up to 30 psi.

To use a fuel pressure tester, first ensure you are working in a well-ventilated area as fuel vapours are highly flammable. With the engine entirely cold, open the hood and find the Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting, ensuring it is leakproof. Turn the ignition to 'on', not 'start', and check the psi reading. A drop in psi over 10 minutes indicates a leak in the fuel system. If the pressure remains the same, the system is holding pressure well.

If the engine is running, you should see a steady fuel pressure, within a few psi of the recommended pressure. Once the engine is warmed up, rev the engine slowly, making sure the pressure rises with the RPMs.

Understanding the Audi A4 Fuel Pressure Sensor's Function

You may want to see also

Frequently asked questions

The required fuel pressure for a TBI 350 is between 9 and 14 psi.

If the fuel pressure is set too high, the engine will run like a carb motor with a big carb or jets that are too big. It will be sluggish and blow black smoke.

The stock fuel pump pressure for a Chevy TBI 350 is between 63 and 67 psi.

TBI systems normally operate around 9 psi but can be bumped up to 12-13 psi. Going much higher than that can lock the injectors.

The fuel pressure for a 5.7 TBI should be around 13-15 psi at all times, from idle to WOT.