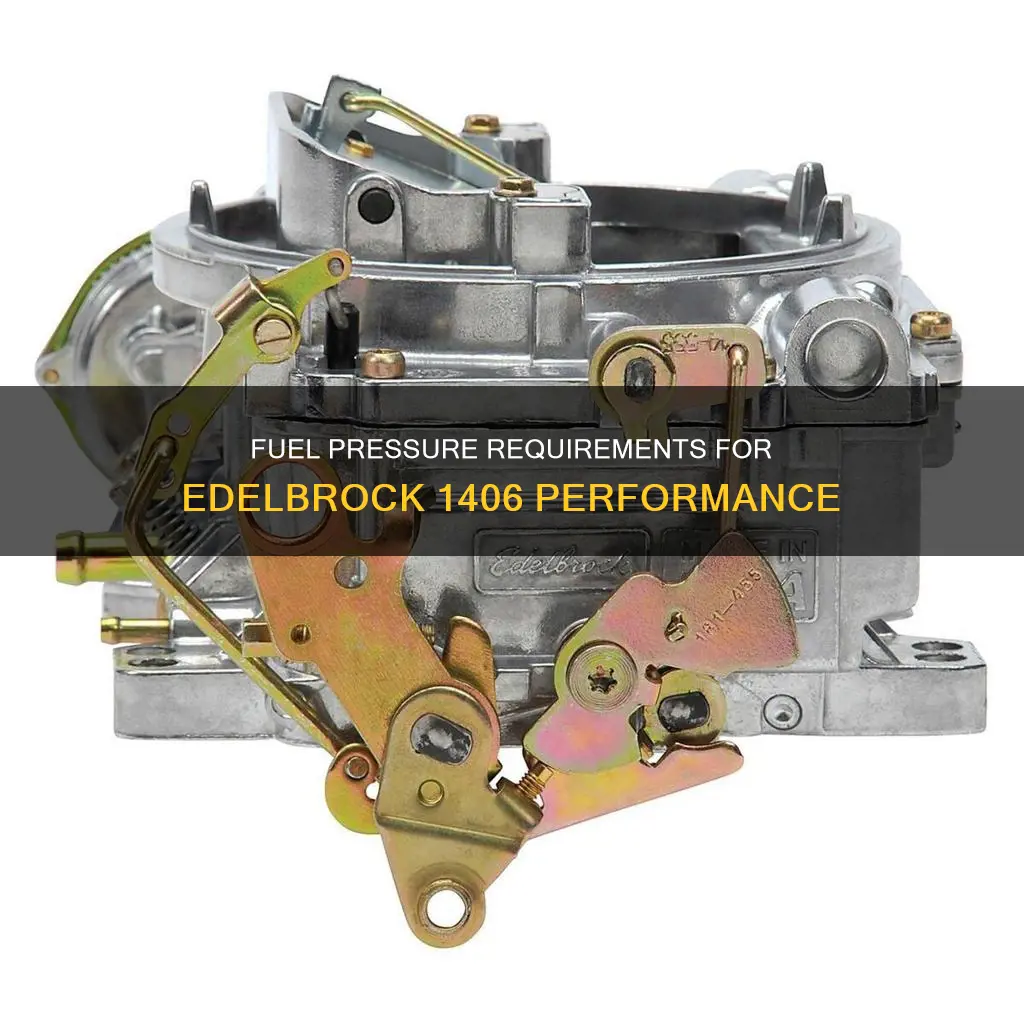

Edelbrock 1406 is a carburettor that has been installed in various vehicles, including trucks, SUVs, and cars. It is important to ensure that the Edelbrock 1406 has the correct fuel pressure to function optimally. The recommended fuel pressure for this carburettor is between 4 and 6 PSI, and going above this range can cause issues such as bogging down when accelerating or turning. However, some sources suggest that up to 7 PSI may be acceptable if the carburettor is not flooding. In addition, factors such as the type of fuel pump, regulator, and fuel lines can also impact the performance of the Edelbrock 1406.

What You'll Learn

- The Edelbrock 1406 carburettor should not have more than 5 psi of fuel pressure

- A regulator should be used to reduce fuel pressure if it is above 6 psi

- Fuel pressure should not be lower than 2 psi at high rpm and WOT

- Fuel filters should be kept away from heat sources to prevent fuel issues

- Fuel pump pressure problems can be caused by deteriorated rubber lines

The Edelbrock 1406 carburettor should not have more than 5 psi of fuel pressure

Users with an Edelbrock 1406 carburettor have reported problems when the fuel pressure is set above 5 psi. In one case, a user with a low-compression 78 400 big block engine and timing around 14 btdc experienced bogging when giving the engine gas and when turning. After installing a fuel pressure regulator and setting the pressure to 5 psi, the issues were resolved.

Another user with a similar setup also experienced bogging issues and resolved them by adjusting the accelerator pump shot size and spring. This user also recommended setting the fuel pressure to a maximum of 5 psi, as specified in the Edelbrock instructions.

It is important to note that some mechanical fuel pumps can output up to 12-13 psi, which is significantly higher than the recommended maximum for the Edelbrock 1406. Therefore, it is essential to use a fuel pressure regulator to ensure that the fuel pressure does not exceed 5 psi.

By maintaining the fuel pressure at or below 5 psi, you can help ensure the proper functioning of your Edelbrock 1406 carburettor and avoid potential performance issues.

Mustang Fuel Pressure Regulator: Choosing the Right One

You may want to see also

A regulator should be used to reduce fuel pressure if it is above 6 psi

The Edelbrock 1406 carburetor has a maximum fuel pressure threshold of 5.5 psi. Fuel pressure above this threshold can cause the needles to move out of their seats. Therefore, a regulator should be used to reduce fuel pressure if it is above 6 psi.

Users have reported that the Edelbrock 1406 works well with a fuel pressure of 5.0-5.25 psi. One user reports that they have used a Carter street pump (4-6 psi) with their Edelbrock 1406 without any issues. However, they warn that the Carter pumps can be noisy. Another user recommends using a deadhead regulator to keep the fuel pressure within the optimal range.

It is important to maintain the correct fuel pressure to ensure the optimal performance of the Edelbrock 1406 carburetor. Fuel pressure that is too high can cause issues such as over-pressurization of the carburetor and overfilling of the float bowls. Therefore, a regulator should be used to reduce the fuel pressure if it exceeds the recommended range.

The type of fuel pressure regulator used can also impact the performance of the carburetor. There are two main types of fuel pressure regulators: blocking style and bypass style. Blocking style regulators do not have a fuel return line, which reduces weight, complexity, and expense. However, they may not be suitable for blow-through forced induction systems and can be more sensitive to debris. On the other hand, bypass style regulators provide a constant effective fuel pressure and enable more accurate pressure settings. They also prolong pump life and reduce pump noise but are more expensive and complex to install due to the additional fuel lines and fittings.

Fuel Pressure Sensor Failure: Common Causes and Solutions

You may want to see also

Fuel pressure should not be lower than 2 psi at high rpm and WOT

Fuel pressure is an important consideration when it comes to the Edelbrock 1406, as maintaining the correct pressure ensures optimal performance and prevents issues such as bogging down or stumbling. The recommended fuel pressure for this carburettor is crucial to its performance.

The Edelbrock 1406 carburettor is a popular choice for many vehicle enthusiasts, and it is important to ensure that it has the correct fuel pressure to function effectively. Fuel pressure that is too low can result in insufficient fuel delivery to the engine, leading to performance issues such as a lean mixture or, in extreme cases, engine stalling. On the other hand, excessive fuel pressure can lead to flooding and other issues. Therefore, maintaining the correct fuel pressure is essential.

The Edelbrock 1406 carburettor typically requires a fuel pressure of around 4 to 6 psi. However, it is important to note that the maximum fuel pressure should not exceed 5.5 psi, as higher pressure can cause the needles to move out of their seats. This can result in fuel delivery issues and potential damage to the carburettor. Therefore, it is recommended to keep the fuel pressure slightly lower than this maximum threshold to ensure optimal performance and prevent any potential issues.

Maintaining a fuel pressure of at least 2 psi at high rpm and wide-open throttle (WOT) is crucial. If the fuel pressure drops below this level, it may indicate that the fuel pump does not have sufficient capacity to meet the engine's demands. In such cases, upgrading to a fuel pump with a higher capacity may be necessary to ensure adequate fuel delivery and engine performance.

Additionally, it is worth noting that some vehicles, such as the 5.0L Ford, may have mechanical pumps that deliver fuel pressure higher than 6 psi at idle. While these vehicles can still perform well, they may be prone to stalling on quick turns and stops when the clutch is disengaged. In such cases, adjusting the fuel pressure using a regulator or a restricted bypass bleed to the fuel return line is recommended to ensure optimal performance and prevent stalling issues.

Fuel Pressure Maintenance for 2002 Suzuki Aerio

You may want to see also

Fuel filters should be kept away from heat sources to prevent fuel issues

Fuel filters play a critical role in a vehicle's fuel supply system, trapping dirt, rust, scale, and other impurities to prevent them from entering the fuel pump, fuel injectors, and engine. While often overlooked, fuel filters are essential for maintaining optimal engine performance and should be regularly maintained to avoid costly repairs.

One important aspect of fuel filter maintenance is ensuring they are kept away from heat sources. Heat can cause fuel to vaporize, leading to potential issues such as engine hesitation, surging, sputtering, or stalling. By keeping fuel filters away from heat sources, you can help maintain the optimal temperature and viscosity of the fuel, ensuring it flows smoothly through the system.

Additionally, heat can accelerate the degradation of the fuel filter material, reducing its effectiveness over time. This can lead to an increased risk of contaminants entering the fuel system and causing damage. By minimizing heat exposure, you can extend the lifespan of the fuel filter and maintain its efficiency in trapping impurities.

Edelbrock, a reputable manufacturer of automotive parts, specifically recommends keeping their fuel filters away from heat sources. In their tuning manual, they advise: "Note that a good filter is large in area, so it may be able to transmit a significant amount of heat to the fuel. It is a good practice to keep the filter away from heat and not allow it to come into contact with any part of the engine."

Following these recommendations can help prevent fuel issues and ensure the optimal performance of your vehicle's fuel system, ultimately saving you time and money on repairs. Regular maintenance and attention to small but critical parts like fuel filters can go a long way in keeping your vehicle running smoothly and efficiently.

Pressure-Testing a Kia GDI: Step-by-Step Guide

You may want to see also

Fuel pump pressure problems can be caused by deteriorated rubber lines

The Edelbrock 1406 has a fuel pressure range of 4-6 PSI. Fuel pump pressure problems can be caused by deteriorated rubber lines, which can be due to a few reasons. Firstly, rubber hoses can deteriorate over time due to exposure to heat, oil, and chemicals in the fuel system. This can cause cracks, swelling, or brittleness, leading to leaks and decreased performance. Additionally, the type of fuel used can also contribute to the degradation of rubber hoses. For example, the use of unleaded fuel or gasoline with additives such as MTBE or ethanol can be particularly damaging to rubber and aluminium hoses.

To prevent fuel pump pressure problems, it is important to regularly inspect and maintain the fuel lines and hoses. This includes visual inspections for any signs of corrosion, leaks, or damage, as well as pressure tests to check for any leaks or pressure loss. It is also recommended to replace rubber hoses every 3-5 years or as per the vehicle manufacturer's guidelines.

In some cases, fuel leaks may be noticeable through the smell of gasoline or the presence of fuel drips or puddles under the vehicle. Leaks can also cause a drop in fuel pressure, resulting in engine misfires and stalling. If you suspect any issues with your fuel lines or hoses, it is important to have your vehicle inspected by a professional technician to ensure the problem is addressed promptly and to prevent any safety hazards.

Furthermore, when replacing deteriorated rubber hoses, it is important to take the necessary safety precautions and ensure the vehicle is parked in a well-ventilated area away from ignition sources. Wear appropriate protective gear, including gloves and safety glasses. Cut out the damaged section of the hose and replace it with a new one of the correct length and diameter. Secure the connections using lubricant, fittings, or clamps. Finally, test the system and perform regular maintenance to prevent future issues.

Fuel Pressure Sensor Failure: Why Your Car Won't Start

You may want to see also

Frequently asked questions

The Edelbrock 1406 should have a fuel pressure of no more than 6 psi, with 5.5 psi being the recommended maximum.

If the fuel pressure is too high, the needles will start moving out of their seats. This can cause the carburetor to eventually get sucked dry.

Edelbrock recommends using their #8190 regulator for fuel pressure issues.