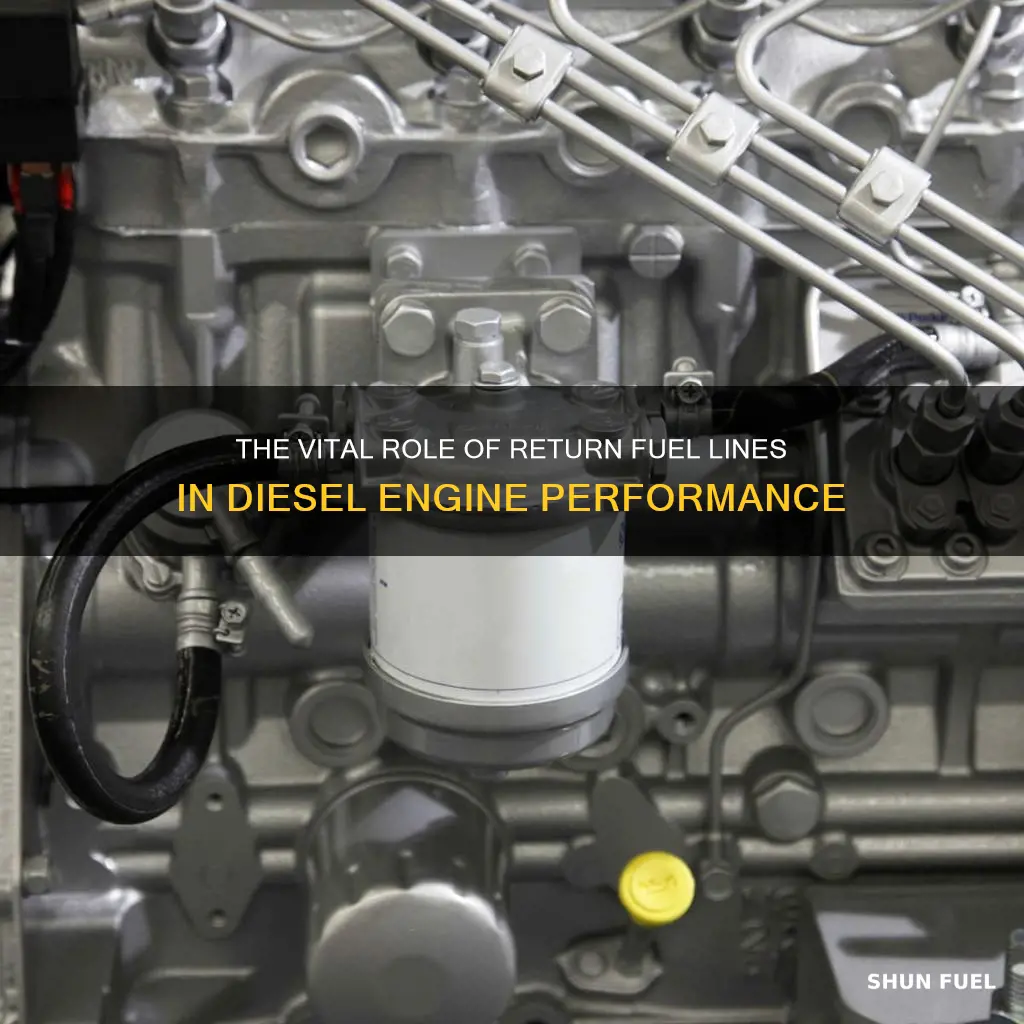

Return fuel lines are a critical component of diesel engines, playing a vital role in ensuring optimal performance and longevity. These lines are responsible for transporting fuel from the fuel tank back to the engine, where it is injected into the combustion chamber. The return fuel lines are designed to handle the high pressure and temperature of the fuel, which is essential for efficient combustion and power generation. Without these lines, the engine would not be able to receive the necessary fuel, leading to reduced performance, increased emissions, and potential damage to the engine components. Understanding the importance of return fuel lines is crucial for maintaining and optimizing the performance of diesel engines.

| Characteristics | Values |

|---|---|

| Function | Return fuel lines are crucial for the proper functioning of a diesel engine. They are responsible for transporting the fuel from the fuel tank back to the engine, ensuring a continuous supply of fuel for combustion. |

| Efficiency | Efficient fuel return lines can improve engine performance by ensuring a consistent and accurate fuel supply, which is essential for optimal combustion and power output. |

| Pressure Regulation | These lines help regulate fuel pressure, ensuring it remains within the required range for efficient engine operation. Proper pressure regulation prevents engine misfires and improves overall efficiency. |

| Fuel Quality | High-quality return fuel lines prevent fuel degradation by minimizing contact with air, thus maintaining the integrity of the fuel and reducing the risk of contamination. |

| Engine Reliability | Well-maintained return fuel lines contribute to the long-term reliability of the diesel engine, reducing the chances of fuel-related issues and potential breakdowns. |

| Emission Control | Proper fuel return lines can help reduce emissions by ensuring complete combustion, which is vital for meeting environmental standards and regulations. |

| Maintenance | Regular inspection and maintenance of return fuel lines are essential to prevent clogs, leaks, and other issues that could lead to engine performance problems. |

| Cost | Investing in high-quality return fuel lines can be cost-effective in the long run, as it reduces the risk of engine damage and costly repairs. |

What You'll Learn

- Engine Performance: Return fuel lines ensure optimal engine performance by maintaining proper fuel pressure and flow

- Fuel Efficiency: Efficient return lines prevent fuel wastage, enhancing fuel economy and reducing emissions

- Engine Reliability: Proper return lines prevent engine damage, ensuring long-term reliability and reducing downtime

- Emission Control: Well-functioning return lines contribute to cleaner emissions by maintaining fuel quality

- Maintenance Cost: Regular maintenance of return lines can prevent costly engine repairs and replacements

Engine Performance: Return fuel lines ensure optimal engine performance by maintaining proper fuel pressure and flow

The role of return fuel lines in a diesel engine is often overlooked, but they are crucial for maintaining optimal engine performance. These lines are an essential component of the fuel system, responsible for ensuring that the engine receives the correct amount of fuel at the right pressure. This is particularly important in diesel engines, which rely on precise fuel injection to operate efficiently and produce power.

In a diesel engine, the fuel system is designed to deliver fuel to the injectors at a specific pressure to ensure accurate atomization and efficient combustion. The return fuel lines play a critical role in this process by managing the flow of fuel back to the fuel tank or reservoir. When the engine is running, the fuel lines are constantly under pressure, and any leaks or blockages can lead to a decrease in fuel pressure, affecting the engine's performance.

The primary function of return fuel lines is to provide a low-pressure path for the fuel to return to the tank or reservoir. This ensures that the fuel system maintains a consistent pressure, which is vital for the engine's operation. If the return lines were not present, the fuel would have to travel through the high-pressure lines, which could lead to excessive pressure buildup and potential engine damage. By providing a separate return path, these lines help regulate the fuel pressure and prevent any unnecessary strain on the engine's fuel system.

Moreover, return fuel lines also contribute to the overall efficiency of the engine. By maintaining proper fuel pressure, they ensure that the injectors deliver the correct amount of fuel to each cylinder. This precise fuel injection results in better combustion, increased power output, and improved fuel economy. Without these lines, the engine might struggle to maintain optimal performance, leading to reduced power, increased fuel consumption, and potential long-term damage.

In summary, return fuel lines are essential for the proper functioning and longevity of a diesel engine. They ensure that the fuel system operates within the required pressure range, allowing for efficient combustion and optimal engine performance. Regular maintenance and inspection of these lines are recommended to prevent any issues and ensure the engine's reliability over time. Understanding the importance of these seemingly simple components can lead to better engine management and overall vehicle performance.

Thunderbird Fuel Line Sizes: Understanding the Pump Hanger Connections

You may want to see also

Fuel Efficiency: Efficient return lines prevent fuel wastage, enhancing fuel economy and reducing emissions

The importance of return fuel lines in a diesel engine cannot be overstated, especially when considering fuel efficiency and emissions. Efficient return lines play a crucial role in optimizing the performance of diesel engines, ensuring that fuel is utilized effectively and minimizing waste. Here's a detailed explanation of how these lines contribute to improved fuel economy and reduced emissions:

Preventing Fuel Wasted: In a diesel engine, the fuel system is designed to deliver fuel to the engine's combustion chamber at precise intervals. Return fuel lines are an integral part of this system, acting as a conduit for excess fuel that is not immediately used. When the engine operates, it draws fuel from the tank and injects it into the combustion chamber. However, during certain engine conditions, such as idling or low-load operation, the engine may not require the full amount of fuel supplied. Efficient return lines ensure that this excess fuel is promptly returned to the fuel tank, preventing wastage. By minimizing fuel loss, these lines contribute to a more efficient fuel management system, allowing the engine to operate with reduced fuel consumption.

Enhancing Fuel Economy: The primary goal of an efficient return fuel line system is to optimize fuel economy. By quickly returning unused fuel to the tank, the engine can maintain a consistent and efficient fuel-air mixture. This results in improved mileage, allowing diesel vehicles to travel farther on a single tank of fuel. Over time, this translates to significant cost savings for vehicle owners, as they spend less on fuel without compromising engine performance. Moreover, better fuel economy means less frequent refueling, which is especially advantageous for long-distance travel or commercial vehicle operations.

Reducing Emissions: Efficient return fuel lines also play a vital role in reducing emissions from diesel engines. When fuel is wasted, it can lead to increased unburned hydrocarbons and other pollutants being released into the atmosphere. By preventing fuel wastage, these lines help maintain a cleaner combustion process. A well-functioning return line system ensures that the engine receives the exact amount of fuel required at any given moment, promoting complete combustion. As a result, the engine emits fewer harmful gases, contributing to improved air quality and compliance with environmental regulations.

In summary, return fuel lines are essential components of a diesel engine's fuel system, directly impacting fuel efficiency and emissions. By preventing fuel wastage, these lines enable engines to operate more economically, reducing fuel consumption and associated costs. Additionally, their role in maintaining efficient combustion processes leads to lower emissions, making them a critical aspect of modern diesel engine design and performance optimization. Understanding and maintaining the integrity of these return lines can significantly contribute to the overall efficiency and environmental friendliness of diesel-powered vehicles.

Step-by-Step Guide: Easily Remove Fuel Line from Eskimo Ice Auger

You may want to see also

Engine Reliability: Proper return lines prevent engine damage, ensuring long-term reliability and reducing downtime

Return fuel lines are a critical component of diesel engines, playing a vital role in maintaining engine reliability and performance. These lines are responsible for transporting the fuel-air mixture from the injectors back to the fuel tank, ensuring that the engine operates efficiently and without issues. Proper return lines are essential to prevent engine damage and downtime, as they help to maintain the engine's overall health and longevity.

One of the primary functions of return fuel lines is to ensure that the engine receives the correct amount of fuel at the right pressure. If the return lines are damaged or clogged, the engine may not receive the necessary fuel, leading to poor performance and potential engine damage. Over time, this can result in increased downtime and costly repairs. Therefore, it is crucial to maintain and inspect these lines regularly to ensure they are in good condition.

The design of return fuel lines is also important for engine reliability. These lines are typically made of durable materials such as stainless steel or high-strength plastics to withstand the high pressure and temperature of diesel fuel. Proper installation and routing of these lines are essential to prevent leaks, blockages, and damage to other engine components. For example, if the return lines are not routed correctly, they may rub against other parts, causing wear and tear, or they may become kinked, leading to reduced fuel flow.

Regular maintenance and inspection of return fuel lines can help identify potential issues before they become major problems. This includes checking for any signs of damage, corrosion, or blockages. If any issues are found, prompt action should be taken to repair or replace the affected lines. Additionally, keeping the fuel tank and lines clean can prevent the buildup of contaminants, which can also impact engine performance and reliability.

In summary, return fuel lines are a critical aspect of diesel engine maintenance, directly impacting engine reliability and performance. Proper installation, regular inspection, and maintenance can help prevent engine damage, reduce downtime, and ensure the long-term reliability of diesel engines. By understanding the importance of these lines, engine owners and operators can take proactive measures to keep their engines running smoothly and efficiently.

The Strange Sound of Frozen Fuel Lines: A Guide

You may want to see also

Emission Control: Well-functioning return lines contribute to cleaner emissions by maintaining fuel quality

The return fuel lines on a diesel engine play a crucial role in emission control and overall engine performance. These lines are responsible for transporting the fuel that has been burned in the engine's combustion process back to the fuel tank, ensuring that the system is refueled and ready for the next cycle. Properly functioning return lines are essential for maintaining fuel quality and, consequently, reducing harmful emissions.

When diesel engines operate, they inject fuel into the combustion chamber, where it mixes with air and is ignited. After the fuel is burned, the exhaust gases are released, and the spent fuel must be returned to the tank. This process is where return fuel lines come into play. These lines ensure that the fuel is efficiently and effectively recycled, preventing any accumulation that could lead to poor engine performance and increased emissions.

One of the key benefits of well-functioning return lines is the maintenance of fuel quality. Over time, diesel fuel can degrade, especially when left in the engine's system. Return lines help to keep the fuel fresh and clean by continuously circulating it. This circulation prevents the formation of harmful deposits and ensures that the fuel remains at an optimal level, promoting efficient combustion and reducing the release of pollutants.

In addition, return fuel lines contribute to emission control by minimizing the risk of fuel leaks. If these lines were to malfunction or become damaged, fuel could leak into the engine's surroundings, leading to potential environmental hazards and increased emissions. Well-maintained return lines ensure that fuel is securely transported back to the tank, preventing any unnecessary release of pollutants into the atmosphere.

Furthermore, the proper functioning of return lines can lead to improved engine performance and longevity. By maintaining fuel quality and ensuring efficient combustion, these lines help to optimize the engine's operation, reducing the likelihood of engine damage caused by poor fuel quality. This, in turn, contributes to cleaner emissions and a more reliable engine over its lifespan.

Unraveling the Mystery: Are All Nitro RC Car Fuel Line Fittings Universal?

You may want to see also

Maintenance Cost: Regular maintenance of return lines can prevent costly engine repairs and replacements

The importance of return fuel lines in a diesel engine cannot be overstated, especially when considering the potential maintenance costs. These lines play a critical role in ensuring that the engine operates efficiently and reliably. Over time, the return fuel lines can become susceptible to wear and tear, blockages, and damage, which can lead to significant and expensive engine issues.

Regular maintenance is key to preventing these costly repairs. By keeping the return fuel lines in good condition, you can avoid the need for major engine overhauls or replacements. One of the primary functions of these lines is to return the fuel from the injectors back to the fuel tank, ensuring a continuous supply of fuel to the engine. If these lines become clogged or damaged, the engine may not receive the correct amount of fuel, leading to poor performance, reduced power, and even potential engine failure.

Maintenance tasks for return fuel lines include regular inspections to check for any signs of damage, corrosion, or blockages. It is recommended to inspect these lines at least once a year or whenever there are concerns about engine performance. During these inspections, look for any cracks, leaks, or blockages caused by debris or contaminants. Cleaning the lines periodically can also help prevent blockages and ensure optimal fuel flow. This can be done using specialized fuel line cleaners or by flushing the system with clean fuel.

In addition to inspections and cleaning, it is crucial to address any issues promptly. If you notice any leaks or damage, it is best to replace the affected lines immediately. DIY kits are available for replacing return fuel lines, but it is recommended to have professional assistance for a proper fit and to ensure the engine's performance is not compromised. Regular maintenance and timely repairs can significantly reduce the risk of major engine breakdowns, which often come with high repair costs.

By investing time and effort into the regular maintenance of return fuel lines, diesel engine owners can save a substantial amount of money in the long run. Preventive measures are always more cost-effective than dealing with the consequences of neglect, which can include expensive engine repairs, unscheduled downtime, and potential safety hazards. Therefore, understanding the importance of these fuel lines and implementing a proactive maintenance strategy is essential for any diesel engine owner.

Are Steel Fuel Lines a Good Choice for EFI Systems?

You may want to see also

Frequently asked questions

Return fuel lines are an essential component of a diesel engine's fuel system. They are responsible for transporting the used or 'return' fuel from the engine back to the fuel tank or the fuel pump, ensuring a continuous and efficient fuel supply.

These lines play a critical role in maintaining the engine's performance and efficiency. By returning the fuel to the tank or pump, they help to maintain a consistent fuel level, ensuring the engine always has the required amount of fuel for optimal operation. This process also helps to prevent fuel accumulation in the lines, which could lead to contamination and potential engine issues.

Yes, the absence or failure of return fuel lines can lead to several issues. Without these lines, the engine may not receive the necessary fuel, resulting in reduced power, poor performance, and even potential engine damage. Additionally, the fuel system may become contaminated, leading to clogged injectors or other fuel-related problems. Regular maintenance and inspection of these lines are crucial to ensure the long-term health of a diesel engine.