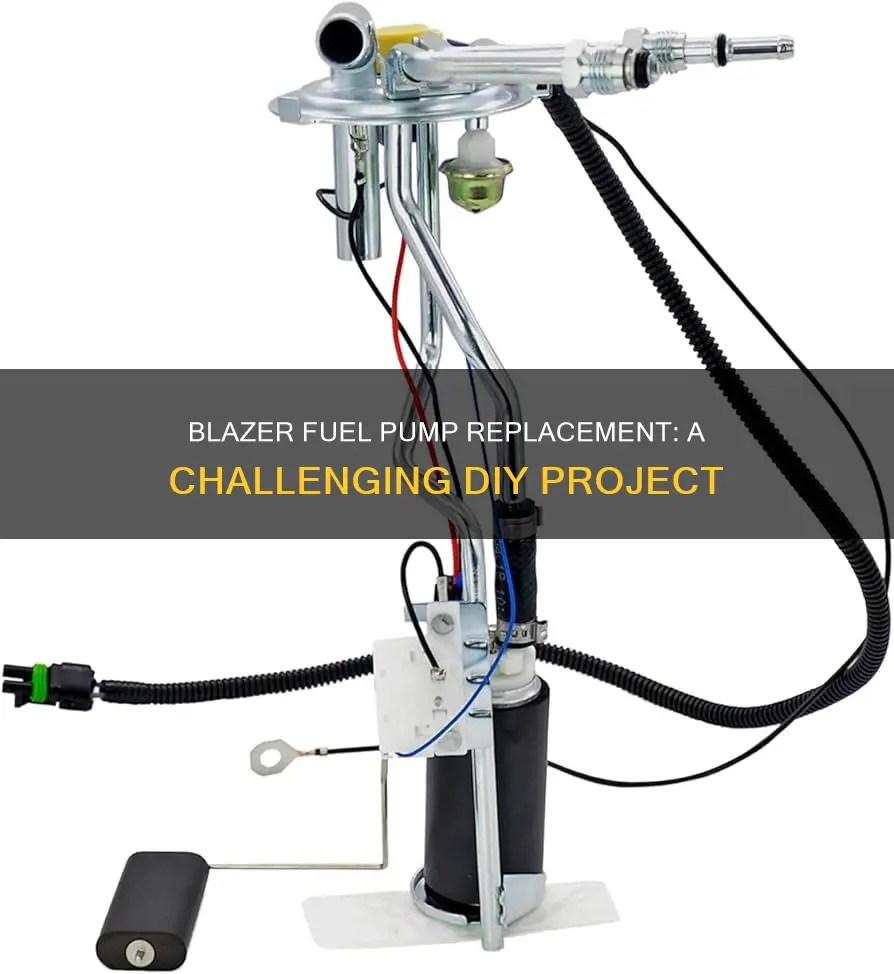

Replacing the fuel pump on a 1990 Blazer can be a challenging task for DIY enthusiasts. The process requires careful disassembly of the vehicle's engine and fuel system, and it's essential to have a thorough understanding of the vehicle's mechanics to avoid any potential issues. This guide will provide a step-by-step overview of the replacement process, including the necessary tools and techniques to ensure a successful and safe repair.

| Characteristics | Values |

|---|---|

| Complexity | Moderate to Difficult |

| Required Tools | Wrenches, Socket Set, Fuel Pump Removal Tool, New Fuel Pump |

| Labor Time | 2-4 hours (depending on experience) |

| Cost | Parts: $50-$150, Labor: $50-$100 |

| Common Issues | Pump Failure, Clogged Fuel Lines, Electrical Problems |

| Safety Precautions | Drain fuel, Disconnect battery, Use safety gear |

| DIY vs. Professional | DIY-friendly but requires careful disassembly and knowledge of fuel systems |

| Common Symptoms | Engine Stalling, Hard Starting, Reduced Power |

| Additional Tips | Refer to the vehicle's manual for specific instructions |

What You'll Learn

- Accessing the Pump: Locate and remove the fuel tank to access the pump

- Diagnosis: Use a fuel pressure gauge to confirm the pump's failure

- Removal: Disconnect electrical connections and release fuel pressure before removing

- Installation: Ensure proper alignment and secure the new pump

- Testing: Verify fuel flow and pressure after installation

Accessing the Pump: Locate and remove the fuel tank to access the pump

To access the fuel pump on a 1990 Blazer, you'll need to start by locating the fuel tank. The fuel tank is typically located on the driver's side of the vehicle, behind the front wheel well. It is often secured with several bolts and clips, so you'll need to remove these to gain access. Carefully inspect the tank and identify the mounting points, as you will need to know where the bolts are located to avoid any damage during removal.

Once you've identified the mounting points, use a socket or wrench to loosen and remove the bolts. Be cautious not to strip the threads, and consider using a lubricant to make the process easier. After removing the bolts, gently pull the fuel tank away from the vehicle. You might need to lift it slightly to clear any obstructions. Place the tank in a secure location, preferably on a flat surface, to prevent any spills or damage.

With the fuel tank removed, you should now have access to the fuel pump. The pump is usually located inside the tank, often towards the bottom. It is connected to the fuel lines and is responsible for delivering fuel to the engine. Carefully inspect the pump for any signs of damage or wear. If it appears to be in good condition, you can proceed with the replacement process. However, if there are any visible issues, it might be best to consult a professional mechanic to ensure a proper repair.

When replacing the fuel pump, it is crucial to follow the manufacturer's instructions or a trusted repair guide. This will ensure that you have the necessary tools and knowledge to complete the task correctly. Remember to disconnect the fuel lines carefully and route them away from the work area to prevent any accidents. Take your time and be methodical in your approach to avoid any complications.

In summary, accessing the fuel pump on a 1990 Blazer involves removing the fuel tank, which requires loosening and removing the mounting bolts. Once the tank is removed, the pump can be accessed inside. Properly identifying the pump's location and condition is essential before proceeding with the replacement. Always exercise caution and refer to relevant resources to ensure a successful repair.

Replacing Fuel Lift Pump: Step-by-Step Guide for Beginners

You may want to see also

Diagnosis: Use a fuel pressure gauge to confirm the pump's failure

To accurately diagnose the failure of the fuel pump in your 1990 Blazer, using a fuel pressure gauge is a crucial step. This tool will help you confirm whether the pump is functioning correctly or if it needs to be replaced. Here's a detailed guide on how to use the fuel pressure gauge for this purpose:

Step 1: Prepare the Vehicle and Tools

Before you begin, ensure the engine is cool to the touch to prevent any potential hazards. Locate the fuel pressure gauge, which is typically connected to the fuel rail or the fuel pump itself. You might need to consult your vehicle's manual to find the exact location. Gather the necessary tools, including the fuel pressure gauge, a jack, and a jack stand (if working on a lift).

Step 2: Disconnect the Battery (Optional)

For added safety, you can disconnect the battery to prevent any accidental starting of the engine during the diagnostic process. This step is optional but recommended for those new to vehicle maintenance.

Step 3: Measure Fuel Pressure

Place the fuel pressure gauge onto the fuel rail or fuel pump fitting. Ensure a secure connection. Start the engine and allow it to idle for a few minutes to reach operating temperature. With the engine running, check the fuel pressure reading on the gauge. A healthy fuel pump should provide a steady pressure reading within the specified range for your vehicle (check your owner's manual for the correct range). If the pressure is low or fluctuating, it indicates a failing or failed fuel pump.

Step 4: Interpret the Results

If the fuel pressure gauge shows a reading outside the normal range, it's a strong sign that the fuel pump is not functioning correctly. Low pressure suggests a possible clog or a failing pump, while fluctuating pressure may indicate an issue with the pump's electrical connection or internal components. In either case, further investigation or replacement of the fuel pump is likely necessary.

Step 5: Document and Proceed

Record the fuel pressure reading and any observations. This data will be valuable when discussing the issue with a mechanic or when ordering a replacement part. If the diagnosis confirms the fuel pump's failure, you can proceed with the replacement, which, as you've researched, can be a challenging task due to the pump's location and the need for specialized tools.

Renewable Energy: A Sustainable Future Beyond Fossil Fuels?

You may want to see also

Removal: Disconnect electrical connections and release fuel pressure before removing

The process of replacing a fuel pump in a 1990 Blazer can be a challenging task, but with the right preparation and knowledge, it is definitely achievable. Here's a step-by-step guide to the removal process, focusing on the critical aspect of disconnecting electrical connections and releasing fuel pressure.

Disconnecting Electrical Connections:

Start by locating the fuel pump, which is typically found inside the fuel tank or close to it. Identify the electrical connections that power the pump. These connections are usually in the form of small wires or connectors. Carefully disconnect these wires, ensuring you note their positions for later reattachment. This step is crucial to prevent any electrical issues during the replacement process.

Releasing Fuel Pressure:

Fuel pressure must be released to safely access and replace the pump. Locate the fuel pressure regulator, which is often found near the engine. This component controls the fuel pressure to the engine. You might need to remove a small hose or connector to access the regulator. Once located, release the pressure by opening the fuel valve or using a fuel pressure release tool. This step is essential to avoid fuel spray or spills, which can be dangerous and cause mess.

After releasing the pressure, you can proceed with removing the old fuel pump. Ensure that you have a clean workspace and wear appropriate safety gear, such as gloves and eye protection, to avoid any potential hazards.

Remember, this process requires patience and a systematic approach. If you're unsure about any step, it's best to consult a professional mechanic or refer to a detailed repair manual specific to your 1990 Blazer model.

Replacing Fuel Line on Ryobi Blower: Step-by-Step Guide

You may want to see also

Installation: Ensure proper alignment and secure the new pump

When replacing the fuel pump on a 1990 Blazer, ensuring proper alignment and secure installation is crucial for a successful repair. Here's a step-by-step guide to help you through this process:

Access the Fuel Pump: Begin by locating the fuel pump, which is typically mounted near the fuel tank. You might need to remove some panels or access panels to get to it. Carefully inspect the pump for any signs of damage or wear, as this will help you determine if the issue is solely with the pump or if there are other underlying problems.

Prepare the New Pump: Before installation, ensure you have the correct replacement pump for your specific Blazer model. Check the specifications and compatibility to avoid any issues. Inspect the new pump for any visible defects or damage during the unboxing process.

Alignment and Installation: Proper alignment is essential to ensure a secure and functional fuel pump. Here's how to do it:

- Locate the mounting points on the fuel tank or the surrounding structure where the pump will be attached.

- Carefully lift the new fuel pump into place, aligning it with the mounting points. Ensure that the pump's electrical connections are accessible and properly positioned.

- Secure the pump using the appropriate fasteners. Tighten them by hand first, then use a torque wrench to achieve the recommended specifications. Over-tightening can damage the pump or its mounting, so be cautious.

- Double-check the alignment and ensure the pump is firmly in place. You may need to temporarily secure it with a piece of tape or a temporary fastener to prevent it from shifting during the final tightening.

Final Steps: After securing the pump, it's time to make the necessary electrical connections. Connect the wires from the new pump to the corresponding terminals, ensuring a proper match. Test the fuel pump's functionality by starting the engine and checking for fuel flow. If everything is in order, you can proceed with the remaining steps of the repair or maintenance.

Remember, taking your time during the installation process is essential to avoid any complications. If you're unsure about any step, consult the vehicle's manual or seek guidance from an experienced mechanic to ensure a successful fuel pump replacement.

Replacing the Fuel Filter on Your JD 110 TLB: A Step-by-Step Guide

You may want to see also

Testing: Verify fuel flow and pressure after installation

After replacing the fuel pump in your 1990 Blazer, it's crucial to verify that the system is functioning correctly to ensure optimal performance. Here's a step-by-step guide on how to test the fuel flow and pressure:

Step 1: Prepare the Vehicle

Before starting the test, ensure the vehicle is in a safe and stable position. Turn off the engine and allow it to cool down if it has been running. Engage the parking brake for added safety.

Step 2: Check for Fuel Flow

- Locate the fuel filter, which is typically found near the engine compartment.

- Remove the fuel filter housing and place a clean container or a fuel flow gauge under the filter to catch any fuel that drips out.

- Start the engine and let it run for a few minutes.

- Observe the fuel flow. It should be steady and continuous, indicating that the pump is delivering fuel to the engine. If there's a noticeable drop or interruption in the flow, it might suggest an issue with the pump or the fuel lines.

Step 3: Measure Fuel Pressure

- You can use a fuel pressure gauge for this test. Connect the gauge to the fuel rail or the fuel pump outlet, ensuring a secure connection.

- Start the engine and allow it to idle.

- Read the fuel pressure gauge. The pressure should be within the specified range for your vehicle, typically around 6-8 psi for a 1990 Blazer. If the pressure is too low, it may indicate a faulty pump or a restricted fuel line.

- Rev the engine slightly and check the pressure again. It should increase proportionally, indicating proper pump operation.

Step 4: Listen for Pump Operation

While the engine is idling, listen carefully to the fuel pump. It should be operational and producing a steady humming or whirring sound. If there's no sound or an irregular noise, it could mean the pump isn't functioning correctly.

Step 5: Test at Higher Speeds

For a comprehensive test, drive the vehicle at various speeds and listen for any changes in the pump's operation. The pump should engage and disengage as needed to maintain fuel supply.

Remember, if any of these tests reveal issues, further investigation or professional assistance may be required to identify and resolve the problem.

Fuel Injection: The Evolution Beyond Carburetors

You may want to see also

Frequently asked questions

Replacing the fuel pump on a 1990 Blazer can be a challenging task, especially for those with limited mechanical experience. The process involves removing several components, including the engine air filter, intake manifold, and various hoses and wiring. It requires a good understanding of engine mechanics and careful disassembly to avoid damage to other parts.

You will need a set of socket and wrenches, a fuel pump removal tool (if required), a new fuel pump, and possibly a new fuel filter. Additionally, have a lift or jack stands to support the vehicle safely, a new oil filter, and any necessary cleaning supplies.

Yes, it's crucial to follow a step-by-step guide. Start by draining the fuel tank and disconnecting the fuel lines. Then, remove the air filter and intake manifold, being careful with the wiring and hoses. Access the fuel pump housing and carefully extract the old pump. Install the new pump, ensuring proper alignment, and secure all connections. Reassemble the engine components in reverse order.

While it is possible to replace the fuel pump yourself, it is a complex task that requires patience and mechanical proficiency. If you're unsure or uncomfortable with the process, it's advisable to seek professional assistance to ensure the job is done correctly and safely.

Keep an eye out for any signs of fuel leaks, as these can be dangerous. Ensure all connections are tight and secure. Check for any damage to the fuel lines or pump during removal. Also, verify that the new pump is functioning correctly before reassembling the vehicle.