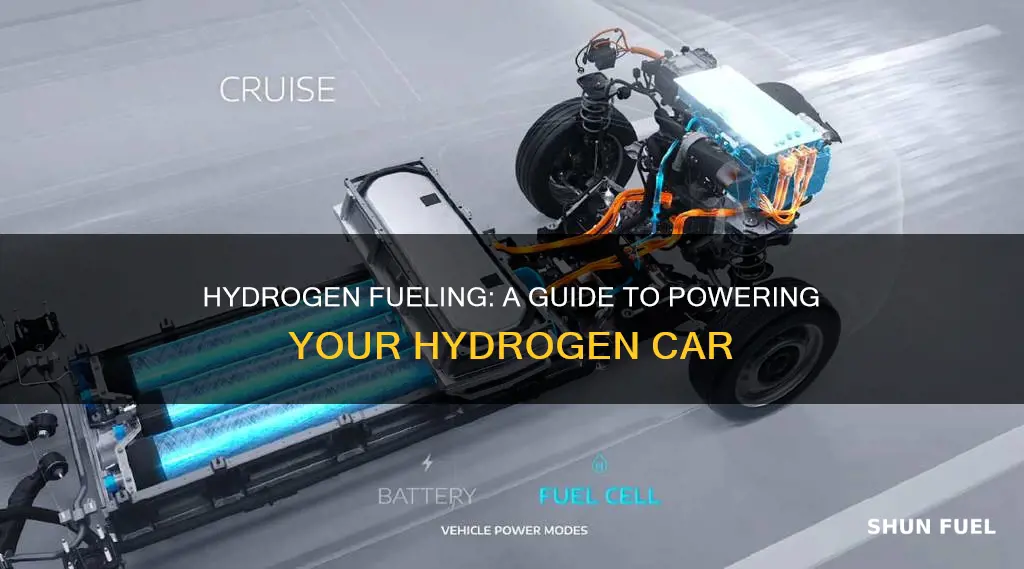

Hydrogen cars are an innovative and eco-friendly alternative to traditional gasoline vehicles, but they require a unique fueling process. Unlike conventional cars, hydrogen vehicles need to be refueled with compressed hydrogen gas, which is stored in specialized tanks. The fueling process involves connecting the vehicle to a hydrogen fueling station, where the high-pressure gas is transferred into the car's fuel tank. This process is similar to refueling a conventional car but requires specialized equipment and infrastructure. Understanding the fueling process is essential for anyone considering a hydrogen car, as it highlights the accessibility and convenience of this emerging technology.

What You'll Learn

- Hydrogen Production: Extracting hydrogen through steam methane reforming or electrolysis

- Storage Systems: High-pressure tanks or metal hydrides for efficient hydrogen storage

- Fuel Cells: Electrochemical devices converting hydrogen and oxygen into electricity and water

- Refueling Process: Hydrogen is injected into the fuel cell stack for power generation

- Infrastructure Development: Building hydrogen refueling stations for widespread adoption

Hydrogen Production: Extracting hydrogen through steam methane reforming or electrolysis

Hydrogen, a versatile and clean-burning fuel, is a key player in the transition to a sustainable energy future. When it comes to fueling hydrogen cars, the process begins with the production of hydrogen itself, which can be achieved through various methods, including steam methane reforming and electrolysis.

Steam methane reforming is a widely used industrial process for hydrogen production. It involves reacting methane, a natural gas component, with steam at high temperatures and pressures. This reaction, known as the steam reforming process, produces hydrogen and carbon monoxide (CO). The chemical equation for this process is:

CH4 + H2O → CO + 3H2

In this process, methane is heated to around 1000°C, and steam is injected into the reactor. The high temperature causes the methane to break down into hydrogen and carbon monoxide. The resulting hydrogen is then typically purified to remove any impurities. This method is highly efficient and has been used for decades in the production of hydrogen for various industrial applications.

Electrolysis is another method for generating hydrogen, particularly when renewable energy sources are involved. This process involves passing an electric current through water, splitting it into hydrogen and oxygen. The electrolysis reaction can be represented by the following equation:

2H2O → O2 + 2H2

In this process, water is electrolyzed using an electric current, typically generated from renewable sources like solar or wind power. The current causes the water molecules to dissociate into hydrogen and oxygen. The hydrogen produced can then be compressed and stored for use in fuel cell vehicles. Electrolysis offers a more sustainable approach to hydrogen production, especially when combined with green energy sources.

Both steam methane reforming and electrolysis play crucial roles in the hydrogen economy. Steam methane reforming provides a reliable and established method for large-scale hydrogen production, while electrolysis offers a more environmentally friendly option, especially when powered by renewable energy. The choice of production method depends on factors such as availability of resources, energy sources, and the desired scale of hydrogen production.

Fuel Filter Issues: Why Your Car Won't Start

You may want to see also

Storage Systems: High-pressure tanks or metal hydrides for efficient hydrogen storage

The efficient storage of hydrogen is a critical aspect of fueling hydrogen cars, and there are several innovative storage systems employed to address this challenge. One of the most common methods is the use of high-pressure tanks, which provide a compact and lightweight solution for storing hydrogen gas. These tanks are designed to withstand extremely high pressures, often reaching several hundred bars, allowing for a significant amount of hydrogen to be stored in a relatively small space. The high-pressure storage system is particularly advantageous for vehicles as it enables a longer driving range with a smaller tank compared to other storage methods. When refueling a hydrogen car, the process involves compressing hydrogen gas into these high-pressure tanks, ensuring a rapid and efficient filling process.

Another promising storage technology is based on metal hydrides, which offer a unique approach to hydrogen storage. Metal hydrides, such as sodium alanate (NaAlH4), have the ability to absorb and release hydrogen gas through a reversible chemical reaction. This process allows for the storage of hydrogen in a solid-state form, providing a safe and efficient alternative to compressed gas. Metal hydride storage systems are often used in stationary applications but have shown potential for mobile applications as well. During refueling, the hydrogen car's system interacts with the metal hydride material, causing it to release or absorb hydrogen, thus enabling the vehicle to be powered.

The choice between high-pressure tanks and metal hydrides depends on various factors, including vehicle design, driving range requirements, and infrastructure availability. High-pressure tanks are currently more prevalent in the market due to their maturity and proven performance, especially in fuel cell vehicles. However, ongoing research and development efforts are focused on improving metal hydride technology, aiming to enhance its energy density and safety. This includes exploring new materials and storage mediums to optimize the performance and efficiency of hydrogen storage systems.

In summary, the storage of hydrogen in hydrogen cars is a complex yet essential process, and both high-pressure tanks and metal hydrides play significant roles in this technology. High-pressure tanks provide a practical solution for on-board storage, ensuring a convenient refueling process, while metal hydrides offer a chemical storage method with potential advantages in terms of safety and energy density. As the hydrogen vehicle market continues to grow, advancements in storage systems will be crucial to supporting widespread adoption and addressing range anxiety concerns.

Electric Dreams: Do Automated Cars Need More Gas?

You may want to see also

Fuel Cells: Electrochemical devices converting hydrogen and oxygen into electricity and water

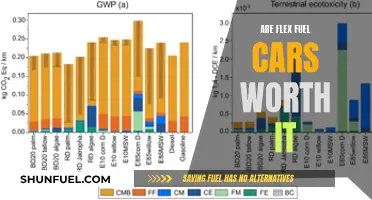

Fuel cells are electrochemical devices that play a crucial role in the operation of hydrogen-powered vehicles. These cells are the heart of the power system in hydrogen cars, converting chemical energy into electrical energy through a process that involves hydrogen and oxygen. The primary function of a fuel cell is to generate electricity through a reaction between hydrogen and oxygen, producing water as a byproduct. This process is highly efficient and environmentally friendly, making it an attractive alternative to traditional internal combustion engines.

The basic structure of a fuel cell consists of an anode, a cathode, and an electrolyte membrane. Hydrogen gas is supplied to the anode, where it undergoes a chemical reaction, releasing electrons and forming protons. These electrons are then transferred through an external circuit, providing the electrical power needed to run the vehicle. The protons, however, move through the electrolyte membrane to reach the cathode. At the cathode, oxygen from the air combines with the protons and electrons returning from the circuit, resulting in the formation of water molecules. This electrochemical reaction is the key to the fuel cell's functionality.

The efficiency of fuel cells is remarkable, as they can convert a significant portion of the chemical energy in hydrogen to electrical energy. This is in stark contrast to conventional combustion engines, which waste a considerable amount of energy as heat. The high efficiency of fuel cells is one of the primary reasons why they are considered a promising technology for powering vehicles, offering a cleaner and more sustainable alternative to traditional fuel sources.

In the context of hydrogen cars, fuel cells are typically paired with a storage system for hydrogen gas. This hydrogen is supplied to the fuel cell, where it undergoes the electrochemical reaction, generating electricity. The process is rapid and efficient, allowing for quick refueling compared to the time required for traditional gasoline or diesel refueling. This makes hydrogen cars convenient for everyday use, addressing the range and refueling concerns associated with early electric vehicle technologies.

The development of fuel cell technology has been a significant focus in the automotive industry, with ongoing research and development aimed at improving efficiency, reducing costs, and enhancing the overall performance of hydrogen-powered vehicles. As the world seeks more sustainable transportation options, fuel cells are poised to play a vital role in the future of clean and efficient mobility.

Flex Fuel Flexibility: Can Your Car Run on Regular Gas?

You may want to see also

Refueling Process: Hydrogen is injected into the fuel cell stack for power generation

The process of refueling a hydrogen car involves a unique and efficient method of replenishing its energy source. When you're ready to refuel, you'll typically locate the hydrogen fueling nozzle, which is usually positioned at the front or side of the vehicle, similar to a conventional gasoline or diesel pump. The nozzle connects to the car's fueling port, which is designed to accommodate the specific type of hydrogen fuel required.

As you begin the refueling process, high-pressure hydrogen gas is carefully injected into the fuel cell stack, a critical component of the vehicle's power generation system. This stack is essentially a series of fuel cells arranged to maximize efficiency. Each fuel cell consists of two electrodes, an anode and a cathode, separated by a membrane. The injected hydrogen gas is directed to the anode, where it undergoes a chemical reaction with oxygen from the air, facilitated by a catalyst. This reaction produces electricity, which is then used to power the car's electric motor.

The refueling process is remarkably quick, often taking just a few minutes, compared to the time required to refuel conventional vehicles. This efficiency is one of the key advantages of hydrogen fuel cell technology. During refueling, the hydrogen gas is compressed and stored in the vehicle's fuel tank, which is designed to withstand high pressures. The fuel tank is typically located in the vehicle's underbody or rear, ensuring it is well-protected.

It's important to note that the refueling infrastructure for hydrogen vehicles is gradually expanding, with more hydrogen fueling stations becoming available. These stations provide the necessary high-pressure hydrogen gas, ensuring that drivers can conveniently refuel their vehicles. The process is designed to be user-friendly, allowing drivers to quickly and easily replenish their hydrogen fuel, making it a practical and sustainable transportation option.

In summary, refueling a hydrogen car involves the precise injection of hydrogen gas into the fuel cell stack, where it undergoes a chemical reaction to generate electricity. This efficient process enables hydrogen vehicles to provide clean and sustainable transportation, contributing to a greener future.

Fuel Filter Failure: When Your Car Suddenly Shuts Down

You may want to see also

Infrastructure Development: Building hydrogen refueling stations for widespread adoption

The widespread adoption of hydrogen fuel cell vehicles relies heavily on the development of a robust and accessible infrastructure for refueling. Hydrogen refueling stations, often referred to as hydrogen fueling stations, are the critical infrastructure needed to support the growing number of hydrogen-powered cars on the road. These stations provide the necessary hydrogen gas to refuel vehicles, ensuring they can travel long distances without range anxiety.

Infrastructure development for hydrogen refueling stations involves several key considerations. Firstly, location planning is essential. These stations should be strategically placed along major transportation routes, in urban areas, and in locations convenient for the public. Proximity to highways, city centers, and residential areas will encourage drivers to choose hydrogen vehicles over traditional gasoline or diesel cars. For instance, placing stations near major highways can cater to long-distance travelers, while stations in urban settings can serve as convenient refueling points for city dwellers.

Secondly, the design and construction of these stations require careful planning. A typical hydrogen refueling station consists of a hydrogen compressor, storage tanks, and dispensing nozzles. The compressor increases the pressure of the hydrogen gas to ensure it can be safely stored and dispensed. Storage tanks, often made of composite materials, are designed to hold large volumes of hydrogen gas at high pressure. The dispensing nozzles are specialized to deliver hydrogen gas efficiently and safely into the vehicle's fuel tank. Building such stations requires specialized knowledge and equipment, often involving collaboration between engineers, architects, and hydrogen fuel experts.

Additionally, safety is a critical aspect of infrastructure development. Hydrogen gas is highly flammable and requires stringent safety measures. Refueling stations must adhere to strict safety codes and regulations, including fire suppression systems, leak detection mechanisms, and secure storage areas. Regular maintenance and inspections are also necessary to ensure the safety and reliability of the stations.

Finally, the financial investment in building and maintaining these refueling stations is substantial. Governments and private investors play a crucial role in funding such projects. Incentives and grants can be provided to encourage the development of hydrogen infrastructure. As the demand for hydrogen vehicles increases, the economic viability of these stations will improve, creating a sustainable ecosystem for hydrogen fuel cell technology.

In summary, the widespread adoption of hydrogen cars is closely tied to the establishment of a comprehensive hydrogen refueling infrastructure. This involves strategic location planning, specialized station design, stringent safety measures, and significant financial investment. As the world transitions towards cleaner energy sources, the development of hydrogen refueling stations will be instrumental in supporting the growing hydrogen vehicle market.

Flex Fuel Flexibility: Unleaded Compatibility Explained

You may want to see also

Frequently asked questions

Hydrogen cars are refueled using a process called "compression" or "dispensing." You'll need to locate a hydrogen fueling station, which is similar to a gas station. The fueling process involves connecting a high-pressure hose to the car's fuel tank and releasing hydrogen gas into the tank. This is done using a specialized pump that compresses the hydrogen to the required pressure.

The fueling time for a hydrogen car can vary depending on the model and the fueling station's setup. Typically, it takes around 3-5 minutes to fill up a hydrogen tank, which provides a range similar to that of a conventional gasoline or diesel vehicle. Some stations offer faster dispensing options, but it's always best to check with the station's staff for specific fueling times.

No, you cannot use regular gas stations for refueling hydrogen cars. Hydrogen fueling stations are specifically designed to handle the unique requirements of hydrogen gas. Regular gas stations are not equipped to dispense hydrogen and may not have the necessary safety measures in place. It's essential to locate authorized hydrogen fueling stations to ensure a safe and efficient refueling process.

Hydrogen cars generally require less maintenance compared to traditional internal combustion engine vehicles. However, it's recommended to follow the manufacturer's guidelines for regular maintenance checks, including inspections of the fuel system, battery, and other components. Proper maintenance ensures the longevity and optimal performance of your hydrogen vehicle.