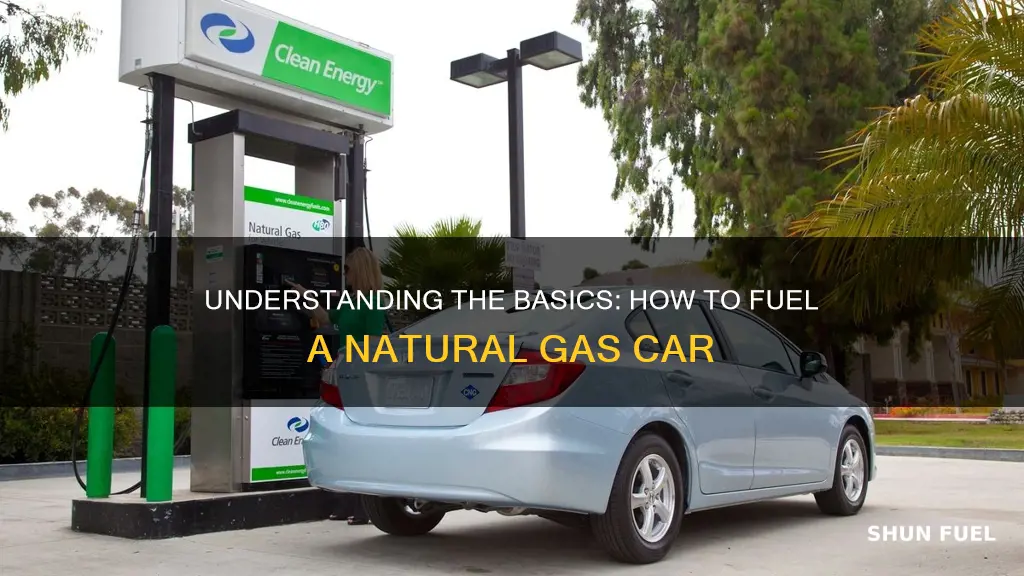

Natural gas vehicles (NGVs) are an eco-friendly alternative to traditional gasoline cars, and understanding how to fuel them is essential for their efficient operation. These vehicles run on compressed natural gas (CNG) or liquefied natural gas (LNG), which is stored in specialized tanks. The fueling process involves connecting a vehicle's fuel tank to a natural gas dispenser, which then injects the gas under high pressure into the tank. This method is similar to refueling a conventional car with gasoline, but with the added benefit of a cleaner, more sustainable fuel source. The process is quick and convenient, often taking just a few minutes, and can be done at dedicated natural gas fueling stations or, in some cases, at home with the right equipment.

What You'll Learn

- Gas Type: Natural gas cars use compressed natural gas (CNG) or liquefied natural gas (LNG)

- Fuel Storage: Tanks are typically located under the vehicle's floor or in the trunk

- Fueling Process: Cars are refueled at dedicated stations using specialized nozzles and connectors

- Fuel Injection: Gas is injected directly into the engine's cylinders for efficient combustion

- Engine Design: Engines are optimized to run on natural gas, with modified combustion chambers

Gas Type: Natural gas cars use compressed natural gas (CNG) or liquefied natural gas (LNG)

Natural gas vehicles (NGVs) are an eco-friendly alternative to traditional gasoline or diesel cars, and they run on a different type of fuel: compressed natural gas (CNG) or liquefied natural gas (LNG). These gases are derived from natural sources and offer a cleaner and more sustainable option for transportation.

CNG is the more common fuel for natural gas cars. It is compressed to a high pressure, typically around 3,000-3,600 psi, to occupy a smaller volume and make it easier to store in the vehicle's fuel tank. The high-pressure CNG is stored in a special tank, often located in the trunk or rear of the car, and is delivered to the engine when the vehicle is fueled. When the driver pulls the fuel nozzle from the tank, a regulator reduces the pressure to a safe level for the engine to operate.

LNG, on the other hand, is a more specialized fuel. It is liquefied by cooling natural gas to extremely low temperatures, often below -160°C (-256°F). This process reduces the volume of the gas, making it easier to store and transport. LNG is then vaporized and compressed to a high pressure before being supplied to the vehicle. Due to its lower temperature and volume, LNG requires a different fueling infrastructure and specialized tanks to handle the unique challenges of storing and transporting this fuel.

Fueling a natural gas car is a straightforward process. The driver parks the vehicle near a fueling station and connects the fuel nozzle to the CNG tank's port. The nozzle has a built-in pressure regulator that controls the flow of gas into the tank. The fueling process is similar to refueling a gasoline car, but the nozzle and tank are specifically designed for CNG or LNG. After a few moments, the vehicle is ready to drive, and the driver can enjoy the benefits of a cleaner-burning engine.

It's important to note that natural gas cars require regular maintenance to ensure optimal performance and fuel efficiency. This includes routine checks of the fuel system, such as the pressure regulators and injectors, to ensure they are functioning correctly. Additionally, keeping the vehicle's engine and other components well-maintained will contribute to the overall longevity and reliability of the natural gas-powered vehicle.

Can Your Hyundai Car Run on Ethanol Fuel? Discover the Facts!

You may want to see also

Fuel Storage: Tanks are typically located under the vehicle's floor or in the trunk

Natural gas vehicles (NGVs) have gained popularity as an eco-friendly alternative to traditional gasoline or diesel cars. One of the key components of these vehicles is the fuel storage system, which is designed to safely and efficiently hold the natural gas required for operation. The storage tanks in natural gas cars are strategically placed to ensure optimal performance and safety.

In most natural gas vehicles, the fuel tanks are located beneath the vehicle's floor or in the trunk area. This placement is carefully considered to maintain the car's center of gravity and ensure a low-slung profile, which contributes to better handling and stability. By positioning the tanks low to the ground, the vehicle's overall balance is improved, making it more responsive and safer to drive. This design also helps to minimize the risk of fuel spillage in the event of an accident, as the tanks are protected by the vehicle's structure.

The fuel tanks in natural gas cars are typically made of lightweight, high-strength materials such as aluminum or composite materials. These materials provide excellent corrosion resistance and ensure the tanks can withstand the high pressure required to store natural gas. The tanks are often designed with multiple layers of protection, including a protective outer layer, to prevent any potential leaks or damage.

Natural gas fuel tanks are designed to be compact and efficient, allowing for optimal space utilization within the vehicle. This compact design ensures that the car maintains its overall aesthetics and functionality, providing a similar driving experience to conventional vehicles. The tanks are often integrated with the vehicle's frame or body, ensuring a seamless and streamlined appearance.

When refueling a natural gas car, the process is similar to that of a conventional vehicle. The driver will locate the fuel filler port, usually on the side or rear of the vehicle, and connect the refueling device. The natural gas is then transferred into the storage tank, which is designed to handle the specific pressure and volume requirements of the fuel. This efficient fuel storage system allows natural gas vehicles to have a range comparable to their gasoline or diesel counterparts, making them a viable and sustainable transportation option.

Fuel Filter Swap: Can You Use a Generic Inline Filter on Fuel Injection Cars?

You may want to see also

Fueling Process: Cars are refueled at dedicated stations using specialized nozzles and connectors

The process of fueling a natural gas vehicle (NGV) is a straightforward procedure, but it requires specific equipment and knowledge to ensure a safe and efficient transfer of fuel. Natural gas cars are typically refueled at designated stations, which are equipped with the necessary infrastructure to handle the unique fueling process.

When you arrive at a natural gas fueling station, you'll find pumps specifically designed for NGVs. These pumps are connected to a network of specialized nozzles and connectors that are tailored to the vehicle's fuel system. The fueling station operator or you, if it's a self-service station, will initiate the process by inserting the fueling nozzle into the vehicle's natural gas port. This port is usually located near the front or rear of the car, often in a discreet location to avoid accidental contact.

The fueling nozzle has a unique design to ensure a secure and controlled connection. It typically features a locking mechanism that engages with the vehicle's port to prevent accidental disconnection. Once connected, the nozzle is activated, and the fueling process begins. The natural gas is dispensed under pressure, which is carefully controlled to ensure the vehicle's tank is filled efficiently without any spillage.

During the fueling, the nozzle's design becomes crucial. It often includes a pressure-release valve to prevent over-pressurization, which could lead to potential hazards. The nozzle may also have a visual indicator to show when the fueling is complete, ensuring the driver knows when to disconnect the nozzle. After the fueling is finished, the nozzle is released from the vehicle's port, and the connection is safely broken.

It is important to note that natural gas fueling stations are equipped with safety measures to handle the high-pressure environment. These stations are designed to prevent leaks and ensure the safe transfer of fuel. The specialized nozzles and connectors are engineered to withstand the pressures involved, providing a secure and efficient fueling experience for NGV owners. Understanding this process ensures that drivers can confidently refuel their natural gas vehicles at dedicated stations, contributing to a smooth and sustainable driving experience.

Is Fuel Stabilizer a Must-Have for Your Car?

You may want to see also

Fuel Injection: Gas is injected directly into the engine's cylinders for efficient combustion

Fuel injection is a critical component of modern natural gas vehicles, ensuring efficient combustion and optimal performance. This system directly injects natural gas into the engine's cylinders, where it mixes with air and is ignited, creating the power that propels the vehicle. The process begins with the fuel injection system, which is designed to precisely control the amount of gas delivered to each cylinder. This is achieved through a network of injectors, strategically placed within the engine block. When the driver initiates acceleration or engages the throttle, the engine control unit (ECU) sends a signal to the injectors, commanding them to release the natural gas at the right moment.

The injectors are highly engineered to deliver gas in a fine mist form, ensuring a uniform mixture with the air-fuel mixture in the cylinder. This precise injection process is crucial for efficient combustion, as it allows for better control over the air-fuel ratio. By optimizing this ratio, the engine can burn the natural gas more effectively, resulting in improved power output and reduced emissions. The timing and pressure of the gas injection are carefully managed to ensure that the fuel-air mixture is ignited at the optimal moment, maximizing combustion efficiency.

In natural gas engines, fuel injection plays a vital role in overcoming the challenges associated with the unique properties of this fuel. Natural gas has a lower energy density compared to gasoline, which means it requires more precise injection to achieve the same power output. The fuel injection system compensates for this by delivering a higher volume of gas per cylinder, ensuring that the engine receives the necessary fuel for efficient operation. This precision is further enhanced by the use of advanced electronic controls, which monitor engine parameters and adjust the injection accordingly.

The direct injection of natural gas into the cylinders also contributes to the engine's overall performance and longevity. By avoiding the use of a carburetor, which can introduce air bubbles and reduce fuel atomization, the fuel injection system ensures a more complete and efficient combustion process. This results in improved engine response, smoother operation, and reduced wear on critical engine components. Additionally, the precise control over fuel delivery allows for better engine management, enabling the vehicle to meet emissions standards and provide a reliable driving experience.

In summary, fuel injection is a sophisticated process that enables natural gas vehicles to achieve efficient combustion and optimal performance. By directly injecting natural gas into the engine's cylinders, this system ensures a well-mixed and precisely controlled fuel-air mixture, leading to improved power output and reduced emissions. The use of advanced electronic controls and injectors further enhances the engine's capabilities, making natural gas vehicles a viable and environmentally friendly transportation option.

Strategies to Reduce Fuel Consumption: Tips for Eco-Friendly Driving

You may want to see also

Engine Design: Engines are optimized to run on natural gas, with modified combustion chambers

Natural gas vehicles (NGVs) are an eco-friendly alternative to traditional gasoline or diesel cars, and their fuel system design is a key factor in their efficient operation. When it comes to engine design, natural gas cars require specific modifications to optimize performance and ensure a clean burn. One of the most critical aspects is the combustion chamber, which plays a pivotal role in the combustion process.

The engine design for natural gas vehicles involves creating a combustion chamber that is tailored to the unique properties of natural gas. This fuel has a higher ratio of hydrogen to carbon compared to gasoline, which means it requires a different approach to combustion. The combustion chamber is modified to have a specific shape and volume, allowing for precise control of the fuel-air mixture. This design ensures that the natural gas is efficiently burned, producing the desired power output while minimizing emissions.

In these engines, the combustion chamber is often designed with a unique configuration, such as a pent-roof or pent-roof-like shape. This design feature helps to improve the mixing and atomization of the natural gas and air, creating a more homogeneous mixture. The modified chamber also influences the timing and duration of the combustion process, allowing for better control over the engine's performance and efficiency. By optimizing the combustion chamber, engineers can ensure that the natural gas is burned completely, reducing the formation of harmful pollutants.

Furthermore, the engine's fuel injection system is crucial. It delivers the natural gas in a precise manner, ensuring the correct amount of fuel is mixed with the air at the right time. This system is designed to handle the unique characteristics of natural gas, including its higher compressibility compared to gasoline. The fuel injectors are strategically positioned to direct the gas into the combustion chamber, where it mixes with air and ignites efficiently.

The engine's overall design also considers the use of advanced ignition systems, such as spark plugs or direct injection, to initiate the combustion process. These systems are fine-tuned to work in harmony with the modified combustion chamber, ensuring a smooth and efficient burn. By optimizing the engine's design, including the combustion chamber and fuel injection system, natural gas vehicles can achieve high performance while maintaining lower emissions, making them an attractive and environmentally friendly transportation option.

Exploring Alternative Fuels: Can Cars Run on More Than Gasoline?

You may want to see also

Frequently asked questions

Refueling a natural gas vehicle is similar to filling up a gasoline car. You'll need to locate a natural gas fueling station, which is often marked with a sign indicating "CNG" or "Natural Gas." These stations typically have a dedicated pump that dispenses natural gas directly into your vehicle's fuel tank. Simply park your car close to the pump, open the fuel door, and start the fueling process.

Refueling a natural gas car is straightforward. You'll need to locate the fuel filler door, usually located near the front or rear of the vehicle. Open the door and connect the fueling nozzle to the vehicle's filler port. Ensure the nozzle is properly aligned and locked into place. Then, you can start fueling by pressing the pump button or using the station's controls. The process is similar to filling up a conventional car, but you'll need to monitor the fuel level and stop when your vehicle's tank is full.

Yes, natural gas vehicles can have different fuel tank configurations. The most common types are:

- Underbody Tanks: These tanks are located beneath the vehicle's floor and provide a compact design.

- Side-Mounted Tanks: These tanks are positioned along the sides of the vehicle and offer better weight distribution.

- Rear-Mounted Tanks: In some cases, tanks can be mounted at the rear of the vehicle, providing a lower center of gravity. The specific tank type depends on the vehicle model and design.

Regular maintenance is essential to keep your natural gas car running efficiently. Here are some key points:

- Schedule Servicing: Follow the manufacturer's recommended service schedule for routine maintenance, including fuel system inspections and emissions tests.

- Monitor Fuel Levels: Keep an eye on your vehicle's natural gas gauge to ensure you don't run out of fuel unexpectedly.

- Check for Leaks: Regularly inspect the fuel system for any signs of leaks, as natural gas is highly flammable.

- Use Approved Fuels: Only use the specified natural gas grade recommended by the manufacturer to ensure optimal performance.