Fuel injectors are a critical component of modern automobile engines, playing a crucial role in regulating fuel injection to optimise performance and minimise emissions. The pressure created by fuel injectors is a key factor in their functioning, and understanding how this pressure is generated is essential for both automotive enthusiasts and professionals. The process of creating pressure in fuel injectors involves a combination of mechanical and electronic components working in harmony to ensure precise fuel delivery. This paragraph serves as an introduction to the topic of fuel injector pressure, a subject that warrants further exploration to comprehend the intricacies of modern engine technology.

What You'll Learn

Fuel injectors spray fuel into cylinders at high pressure

Fuel injectors are an essential component of modern engines, playing a critical role in optimising fuel consumption, engine performance, and emissions reduction. The process of fuel injection starts with the selection of the right fuel pump, which is crucial for delivering the required amount of fuel to the injectors.

The fuel injectors themselves are responsible for spraying fuel directly into the engine's cylinders at high pressure. This high-pressure spray ensures a precise and efficient mix of air and fuel, which is vital for optimal combustion and meeting emissions standards. The injectors receive a pressurised fuel supply from the pump, with the pressure ranging from 40-60 psi up to 4500 psi in some cases.

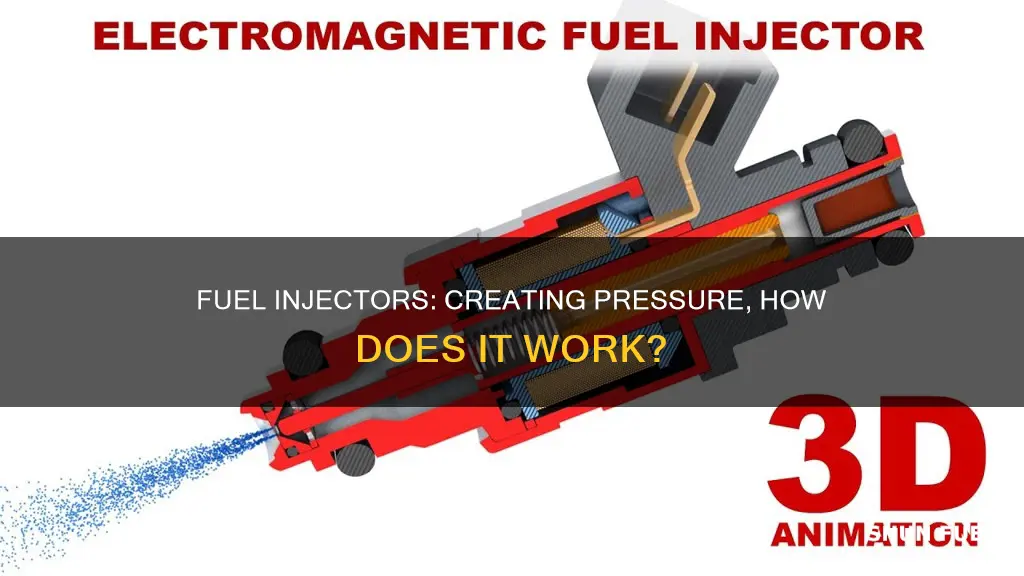

The injectors' ability to spray fuel at high pressure is facilitated by the presence of a solenoid or a piezoelectric stack within the injector body. When an electrical signal is sent to the solenoid or piezoelectric stack, it triggers the injector needle to lift, allowing the pressurised fuel to flow through the injector nozzle. The nozzle features exceptionally fine holes, ensuring an optimal mix of air and fuel.

The high-pressure fuel spray from the injectors is directed into the combustion chamber, where it mixes with compressed air. In diesel engines, the elevated temperature created by the compression stroke causes the air-fuel mixture to auto-ignite, driving the pistons and generating power. This process of direct injection and combustion enables the engine to produce maximum power while minimising fuel consumption and reducing harmful emissions.

By understanding the role of fuel injectors in creating high-pressure fuel sprays, we can appreciate their significance in the overall performance and efficiency of modern engines. The precise delivery of fuel at high pressure is a key factor in ensuring efficient combustion, optimal power output, and reduced environmental impact.

Testing Fuel Pressure: 09 Camry Guide

You may want to see also

Fuel pressure is controlled by a fuel pressure regulator

The FPR works by bleeding off a portion of the fuel flow to the injectors from the fuel pump. Fuel is pumped from the fuel tank to the fuel rail by the fuel pump. The valve in the FPR controls the amount of fuel that is bled from the fuel rail by opening an outlet port, allowing fuel to flow back into the fuel tank. The FPR regulates the fuel pressure against the air pressure/boost, allowing the fuel injector to maintain the perfect ratio between fuel and boost.

The FPR consists of a diaphragm that controls the bypass valve and can open and close to adjust for a steady fuel delivery. When pressure is applied to the top of the regulator, the diaphragm, which is attached to the bypass valve, forces the diaphragm down, reducing the amount of excess fuel. This makes the fuel pumps work harder while the fuel pressure increases.

There are two types of fuel systems: returnless and return-style. A returnless system does not return fuel to the tank, while a return-style system will bleed excess fuel back to the tank through the regulator. A return-style system can maintain a constant effective fuel pressure, which can extend the range of fuel injectors and help them function at lower fuel demands.

Diagnosing a Faulty Fuel Rail Pressure Sensor: A Step-by-Step Guide

You may want to see also

Fuel injectors are part of a vehicle's fuel system

Fuel injectors are a critical component of a vehicle's fuel system. They play a crucial role in regulating the injection of fuel into the engine's internal combustion chamber, where it is mixed with air and ignited to generate power. The latest fuel injector technology helps reduce carbon emissions and improve fuel efficiency by delivering precise amounts of fuel for optimal combustion.

The basic components of a fuel injector system include the fuel injectors themselves, a fuel rail, a rail pressure sensor, a medium-pressure fuel pump, and cam and crank position sensors. The fuel pump pressurizes the fuel, increasing its pressure from around 40-60 psi to between 1500-4500 psi. This pressurized fuel is then delivered through the fuel rail to the fuel injectors, which spray it directly into the engine's cylinders.

The rail pressure sensor is an important component as it measures the pressure in the rail and sends this information back to the engine control unit (ECU). This allows the ECU to adjust the fuel pressure accordingly, ensuring the optimal amount of fuel is delivered to the engine. If the pressure is too high, the ECU will send a signal to decrease the pulse width of the fuel quantity valve, reducing the amount of fuel entering the rail. Conversely, if the pressure is too low, the ECU will increase the pulse width to allow more fuel into the rail, thereby increasing the pressure.

The type of fuel system in a vehicle can also impact the performance of fuel injectors. Returnless fuel systems do not return excess fuel to the tank, while return-style systems bleed excess fuel back to the tank through a regulator. Return-style systems have the advantage of maintaining a constant effective fuel pressure, which can extend the range of fuel injectors and improve their performance at lower fuel demands.

Understanding how fuel injectors work and how pressure is created and maintained is essential for optimizing engine performance, fuel efficiency, and emissions reduction. By selecting the right fuel pump and properly setting up the fuel injector system, vehicle owners and technicians can ensure their vehicles function as intended and meet relevant emissions standards.

Fuel Pressure Secrets: 383 Mopar Performance Tuning

You may want to see also

Fuel injectors enable engines to generate maximum power

The best fuel injectors enable an engine to generate maximum power while minimizing fuel consumption and reducing pollution. They achieve this by delivering accurate fueling with optimized air mixing.

A typical gasoline direct injection system consists of several components: fuel injectors, a fuel rail, a rail pressure sensor, a medium-pressure fuel pump, and cam and crank position sensors. The pump pressurizes the fuel from about 3-4 bar (40-60 psi) to between 100-300 bar (1500-4500 psi). The fuel injectors spray the fuel directly into the cylinders. The fuel rail delivers fuel from the pump to the injectors, and the rail pressure sensor measures the pressure in the rail and sends a signal back to the engine control unit (ECU) indicating the current pressure in the rail.

The ECU plays a critical role in ensuring the engine generates maximum power. It receives data from the rail pressure sensor and other sensors to adjust the fuel injector's performance. If the pressure in the rail is above the target value, the ECU sends a signal to decrease the pulse width command to the fuel quantity valve, reducing the amount of fuel allowed into the rail. Conversely, if the pressure is below the target value, the ECU increases the pulse width command, allowing more fuel into the rail and raising the pressure.

Additionally, the design of the fuel injector itself contributes to the engine's power generation. In diesel engines, for example, the combination of high fuel pressure (up to 37,000 psi) and exceptionally fine injector nozzle holes ensures optimal mixing of air and fuel. This not only enhances power generation but also helps meet stricter emissions standards.

By optimizing fuel injection, engines can achieve maximum power output while reducing fuel consumption and minimizing their environmental footprint.

Sniper EFI: Lowering Fuel Pressure for Performance Tuning

You may want to see also

Fuel injectors reduce carbon emissions

Fuel injectors play a crucial role in the operation of a vehicle's engine, delivering the correct amount of fuel to the combustion chamber. However, they can also significantly impact a vehicle's emissions and carbon footprint.

One of the primary ways fuel injectors affect emissions is through their influence on fuel efficiency. Clogged or worn fuel injectors can lead to poor atomization of fuel, resulting in incomplete combustion. This, in turn, increases emissions of carbon monoxide and hydrocarbons. Additionally, dirty or malfunctioning injectors can cause the engine to run rich, increasing fuel consumption and carbon dioxide emissions.

Regular maintenance of fuel injectors is essential to reducing emissions. Cleaning or replacing clogged or worn injectors improves fuel atomization, leading to more complete combustion and lower emissions of harmful pollutants. Upgrading to more efficient injectors can also improve fuel economy and further reduce emissions.

The role of fuel injectors in controlling the air-fuel ratio is another factor in reducing emissions. When the air-fuel ratio is too rich, with an excess of fuel in the mixture, carbon monoxide and hydrocarbon emissions increase. Conversely, a too-lean mixture with excess air increases nitrogen oxide emissions. Properly functioning fuel injectors maintain the correct air-fuel ratio, helping to keep emissions in check.

The use of alternative fuels, such as biofuels, in vehicles designed for them, can also reduce emissions. Alternative fuels produce fewer emissions during combustion, positively impacting the environment.

In summary, by maintaining and ensuring the proper functioning of fuel injectors, vehicle owners can improve fuel efficiency, reduce carbon emissions, and lower their carbon footprint. Additionally, considering alternative fuels and fuel injection technologies can further contribute to emissions reduction and environmental sustainability.

Removing Fuel Pressure Sensor: A Step-by-Step Guide

You may want to see also

Frequently asked questions

A fuel injector regulates the injection of fuel into an engine's internal combustion chamber where it is mixed with air and ignited.

The injector delivers a precise amount of fuel to ensure efficient combustion. In the cylinder, air is compressed by the upward movement of the piston. As the piston nears the top of its path, an electrical signal is sent to the solenoid, causing the injector needle to lift, and allowing high-pressure fuel to flow through the nozzle and into the combustion chamber to mix with air.

Fuel injectors can play a key role in the energy transition from fossil fuels to cleaner energy sources. By optimising fuel consumption in traditional diesel engines and facilitating the operation of alternative fuel engines, fuel injectors contribute to trucking fleets' efforts to reduce carbon and greenhouse gas emissions.

Rail pressure is the pressure inside the rail. Effective pressure is the actual applied pressure for the injector and is the pressure differential across the injector. Effective pressure is what injector flow rate is based on.