Building fuel pressure is essential for optimal engine performance, and there are several methods to achieve this. One way is to ensure there is no clogging in the fuel filter or faults in the fuel pump, as these issues can lead to low fuel pressure, resulting in stalling and a lack of horsepower. It's also crucial to maintain the correct fuel pressure, which can be checked using a fuel pressure gauge. Additionally, the fuel pressure regulator should be tested to ensure it's functioning correctly. Proper fuel pressure is vital for engine operation and can be maintained through returnless or return-style fuel systems, depending on the vehicle's requirements.

What You'll Learn

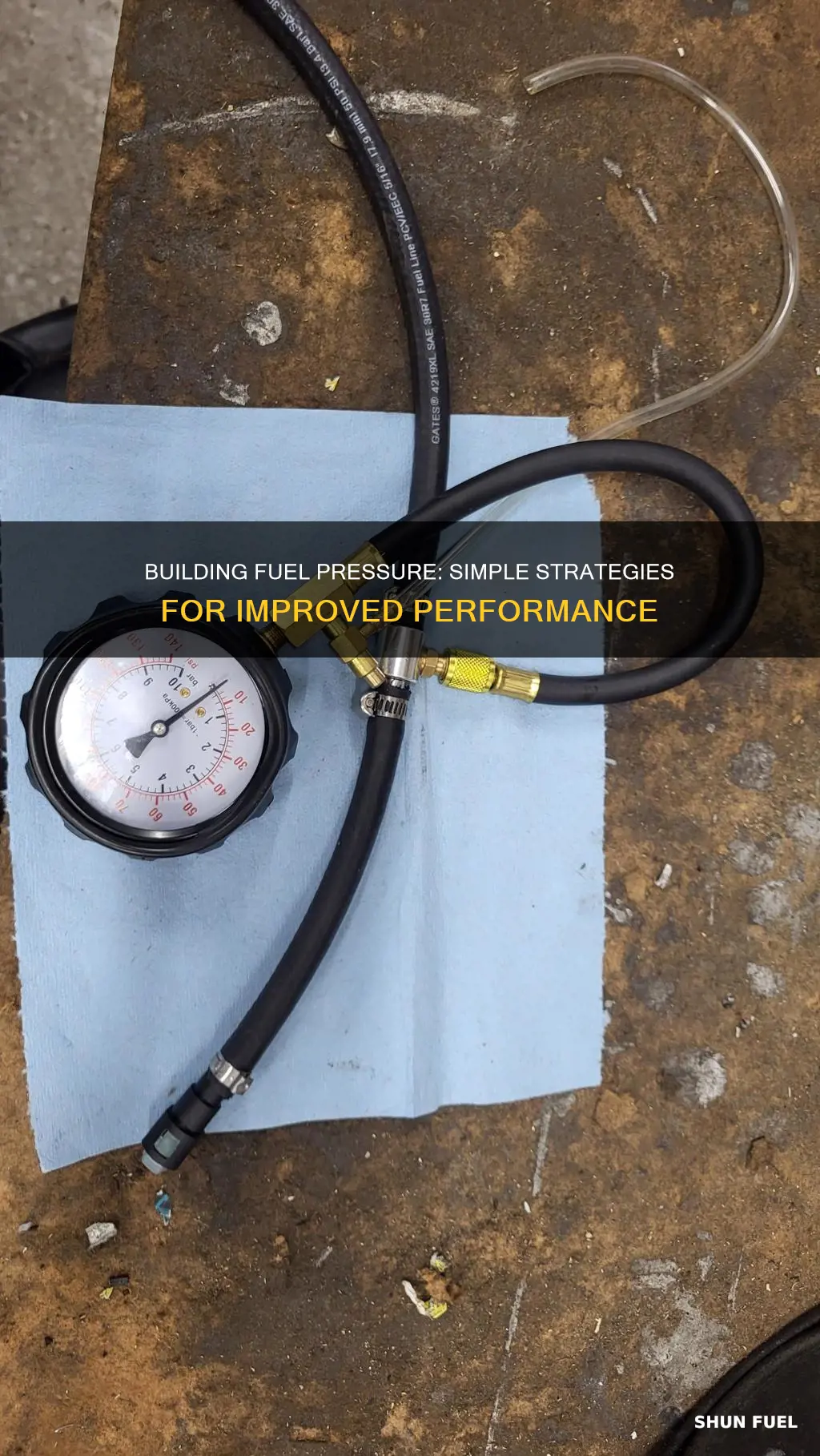

Check fuel pressure with a gauge

Checking your fuel pressure with a gauge is a straightforward process, but it does require some caution as it involves flammable fuel. Here is a step-by-step guide on how to check your fuel pressure with a gauge:

First, locate the fuel pressure testing point, usually found near the car hood's fuel injectors. Ensure you have a suitable fuel pressure gauge with the correct fittings for your vehicle.

Next, disconnect the hose or pipe leading to the injector's rail. Securely connect the pressure gauge to this pipe, ensuring a tight fit to prevent any fuel leakage.

Now, turn the ignition key to the 'on' position. The fuel pressure gauge should indicate the current fuel pressure. Do not turn the engine on yet.

After connecting the gauge and turning the ignition on, wait for about 5-10 minutes to check if the system is holding pressure. If the fuel pressure drops significantly during this time, it indicates a leak in the fuel system.

If the pressure holds, start the engine and let it idle. The fuel pressure gauge should now show a steady fuel pressure, ideally within a few psi of the recommended pressure for your vehicle. You can find the recommended pressure in your car's manual.

Finally, rev the engine slowly and observe the gauge. The fuel pressure should rise with the increase in RPMs.

If your fuel pressure readings are within the specified range and respond appropriately to changes in engine speed, your fuel system is likely functioning correctly.

It is important to note that fuel pressure requirements vary depending on the engine. Older throttle-body injected systems may require as little as 10 psi, while multi-port injection systems can go up to 60 psi. Always refer to your vehicle's manual or a repair manual for the specific fuel pressure values for your car.

Additionally, be cautious when working with fuel, as it is highly flammable. Ensure the engine is cold before beginning, work in a well-ventilated area, and have a fire extinguisher nearby.

Fuel Pressure Gauge: LS1 Engine's Best Friend?

You may want to see also

Faulty fuel pump or clogged filter

A faulty fuel pump or a clogged filter can cause low fuel pressure, which can have a significant impact on engine operation and performance. Low fuel pressure can lead to a lack of horsepower, stalling, and even a no-start condition.

A clogged fuel filter can restrict the flow of fuel to the engine, making it difficult to start. This can cause the engine to crank longer than usual before turning over. A clogged filter can also lead to sluggish acceleration, especially when the vehicle is under load, such as accelerating uphill or carrying heavy loads. The engine may hesitate or stumble as it struggles to get the required amount of fuel for increased power and speed.

In addition, a clogged fuel filter can cause rough idling and, in severe cases, complete engine stalling. The insufficient fuel supply can also lead to increased fuel consumption as the engine compensates by demanding more fuel to maintain performance. A clogged filter can also result in unburnt fuel escaping through the exhaust, causing a strong gas odour in the cabin.

Furthermore, a clogged fuel filter can put a strain on the fuel pump, causing it to work harder to push fuel through the restricted supply line. This can lead to unusual noises coming from the fuel pump and, in some cases, even cause the fuel pump to fail prematurely.

To diagnose a faulty fuel pump or clogged filter, it is recommended to check the fuel pressure using a fuel pressure gauge. If the fuel pressure is low, it may be an indication of a clogged fuel filter or a faulty fuel pump. Regular maintenance and replacement of the fuel filter are crucial to ensure optimal vehicle performance and prevent costly repairs.

Locating Fuel Pressure Check Points on a 2001 Tundra

You may want to see also

Vacuum-operated fuel pressure regulator

A fuel pressure regulator is a device that controls the upper limit of the fuel pressure, ensuring that the fuel injectors receive and dispense fuel at a known rate. All mechanical regulators require some type of return line or bypass to the fuel load.

A vacuum-controlled fuel pressure regulator contains a diaphragm that moves with fluctuations in vacuum pressure. When the fuel pressure at the regulator is high enough, it overcomes the spring's pressure without vacuum assistance. The engine's vacuum is high at idle and assists the valve's opening. The opening valve lowers the fuel pressure at the rail by allowing more fuel to circulate back to the tank through the return line. A kinked and restricted fuel return line raises pressure at the fuel rail.

When the engine accelerates, fuel demand is high, and the intake manifold's vacuum is low. The fuel pressure regulator is closed under these conditions, restricting flow through the return line and increasing fuel pressure at the fuel rail, providing more fuel to the injectors.

To test a vacuum-operated fuel pressure regulator, remove the vacuum line while monitoring fuel pressure. The pressure should increase by 5-15 psi. A ruptured fuel pressure diaphragm leaks fuel into this vacuum line.

The mechanical fuel pressure regulator is a reliable method to regulate fuel pressure. They come in a variety of different designs, both for OE and aftermarket requirements.

Finding Fuel Pressure Problems in Your 2005 Dodge Neon

You may want to see also

Returnless vs return-style systems

Return-style and returnless fuel systems are the two main types of fuel systems in vehicles. Understanding the differences between them is important for fuel system service or repair.

A return-style fuel system is an endless cycle of fuel being pumped from the tank, through a regulator, to the injectors or carburetor. The excess fuel is then sent back to the tank via a fuel pressure regulator. This regulator is a simple mechanical device, typically controlled by engine vacuum. The constant cycle of fuel back into the tank helps to cool the gasoline, mitigating the risk of vapor lock. It also makes engine tuning easier as fuel temperatures are more consistent, and fuel pressure is more stable.

However, a drawback of this system is that the fuel pump is constantly running as long as the engine is on, which can shorten its lifespan. Additionally, the plumbing system can become more complicated due to the need for a separate return line from the regulator to the tank.

On the other hand, a returnless fuel system uses an in-tank pump and regulator, with a single fuel line exiting the tank and travelling to the engine. The pressure is controlled by a computer that monitors engine sensors to determine the required amount of fuel. The computer can adjust the pump speed or fuel injector rate to regulate the fuel pressure.

Returnless systems are becoming more common in newer vehicles due to tightening federal environmental regulations. They reduce the amount of harmful evaporative emissions released from the vehicle and make it easier and cheaper to design and build cars. However, retrofitting a returnless system can be expensive, requiring a new pump, regulator, and plumbing.

In terms of performance, there may be no significant difference between the two systems. While a return-style system offers mechanical simplicity and consistency, a returnless system is perfectly adequate for original equipment and many high-performance applications.

Upgrading Fuel Pressure Regulator: Is It Worth It for Your EV?

You may want to see also

Relief valves and ports

Relief valves are an important safety feature in machinery systems that deal with extremely high pressures. They are designed to open at a preset pressure and discharge fluid until the pressure drops to acceptable levels. When the pressure exceeds a predetermined limit, the relief valve will vent the fluid to a safe location. This prevents damage to pipes or tanks, which could burst and cause extensive damage or harm to people.

Relief valves are used in a wide variety of applications, including engine fuel systems. In this context, relief valves, also known as pressure regulating relief valves, are intended to operate more continuously within the system. The valve stability is critical as pressures and flows will vary while the valve is open.

The relief valve is connected to the machinery or system through its inlet, and its outlet can be open to the atmosphere near the system. The diaphragm acts as a seal between the inlet and outlet connections and the valve body, preventing media from leaking through the valve body when the relief valve is in operation. The seat of the relief valve must be durable and soft enough to not damage the valve, usually made of stainless steel coated with a soft metal.

The valve is a critical component for controlled operation, and its malfunction can lead to media leakage from the machinery or system. It is typically made of stainless steel. The spindle, or plunger, has a valve attached to the bottom, and the spring acts on top of it. The force exerted by the spring is transferred to the valve through the spindle. The material used for the spindle is also stainless steel.

The helical spring must have the proper elasticity strength for the valve seat to open and close at the correct pressure. Adjusting bolts or nuts are used to set the lifting pressure of the valve. The spring and adjusting components are generally made of steel alloy.

Fuel Pressure and Engine Light: What's the Connection?

You may want to see also

Frequently asked questions

Low fuel pressure results in a lack of horsepower, stalling, and a slow or no-start condition. Check your service manual for specifications and use a fuel pressure gauge to check the fuel pressure.

A faulty fuel pump or a clogged fuel filter.

Regularly change your fuel filter and ensure your fuel tank doesn't run below 1/4 full.