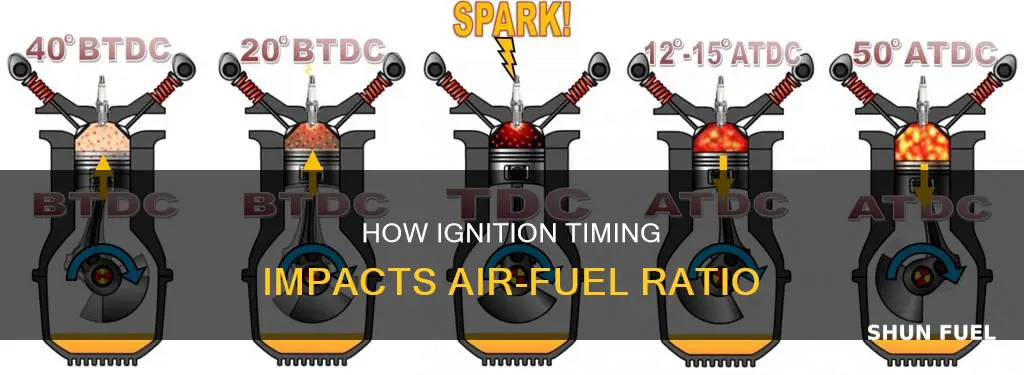

The relationship between ignition timing and air-fuel ratio is a hotly discussed topic. Ignition timing refers to the process of igniting the correct air-fuel ratio at the correct time, which is essential for improving fuel economy or gaining horsepower. Advancing or retarding ignition timing can affect the air-fuel ratio, with some sources claiming that it leads to a leaner mixture, while others argue that it has no direct effect. The consensus is that ignition timing and air-fuel ratio are both crucial factors in engine performance and serve different purposes. The air-fuel ratio focuses on thermal management, ensuring the engine produces the right amount of heat, while ignition timing optimises the mechanical advantage to enhance power efficiency.

| Characteristics | Values |

|---|---|

| Air-fuel ratio | 14.7:1 (Stoichiometric Air to Fuel Ratio) |

| Air-fuel ratio | 12.2:1 to 13.5:1 (Richer mixture for maximum horsepower) |

| Air-fuel ratio | 12.5:1 (Richer mixture for engine longevity) |

| Air-fuel ratio | Leaner for maximum economy |

| Ignition timing | Initial timing, timing advance or curve, and total timing |

| Ignition timing | Initial timing: 10 to 12 degrees for camshaft duration less than 220 degrees |

| Ignition timing | Initial timing: 14 to 16 degrees for camshaft duration less than 240 degrees |

| Ignition timing | Initial timing: 18 to 20 degrees for camshaft duration less than 260 degrees |

| Ignition timing | Total timing: 36 to 40 degrees for early small-block Chevrolet engines |

| Ignition timing | Total timing: 28 to 32 degrees for modern small-block Chevrolet engines |

| Effect of ignition timing change on air-fuel ratio | Advancing ignition timing generally leans out the air-fuel mixture |

| Effect of ignition timing change on air-fuel ratio | Retarding ignition timing generally enriches the air-fuel mixture |

What You'll Learn

The stoichiometric air-fuel ratio

For a complete combustion process, specific quantities of fuel and air need to be supplied to the combustion chamber. The stoichiometric air-fuel ratio, also known as the stoichiometric value, represents the ideal ratio where all the fuel is burned completely, and there are no unburnt fuel quantities in the exhaust gas.

However, in practice, due to operating losses in the induction system, a richer air-fuel ratio of around 12.2:1 to 13.5:1 is often used for maximum horsepower, while a leaner mixture is preferred for better fuel economy. It is important to note that the stoichiometric ratio is just a theoretical ideal, and in reality, engines operate with air-fuel ratios that deviate slightly from this value to optimize performance, fuel efficiency, and emissions.

Fossil Fuels: Burning Question for Climate Change

You may want to see also

The effect of ignition timing on in-cylinder heat flux and temperature

The You may want to see also Ignition timing has a significant impact on engine power. It refers to the process of setting the timing of the spark that ignites the air-fuel mixture in the engine's cylinders. The goal is to ignite the mixture at the precise moment when the piston is at the top of its compression stroke, providing the most effective conversion of the mixture's energy into mechanical force. However, the relationship between ignition timing and engine power is complex. While advancing the timing can increase power, excessive timing advance can lead to a decrease in power and potential engine damage due to overheating and detonation. Additionally, the optimal ignition timing varies depending on factors such as engine speed, load, and design. As a result, mapping the ignition timing correctly can be challenging and often requires the use of a dyno to receive real-time feedback on the impact of timing adjustments. You may want to see also Firstly, it is essential to understand that the air-fuel ratio plays a significant role in engine performance. The stoichiometric air-fuel ratio, which is the ideal ratio for a complete chemical reaction, is approximately 14.7:1 for gasoline engines. This means that for every one part of fuel, 14.7 parts of air are required for a complete burn. However, in reality, engines often operate with a richer or leaner mixture, depending on various factors such as power requirements and engine load conditions. Ignition timing refers to the precise moment the spark plug ignites the air-fuel mixture in the combustion chamber. This timing is crucial because it determines when the combustion process begins and how efficiently the fuel is burned. By advancing or retarding the ignition timing, you can affect the engine's performance and fuel consumption. Advancing the ignition timing generally increases torque, which in turn increases fuel consumption at a given load point. This is because advancing the timing allows for a more complete burn of the air-fuel mixture, resulting in higher cylinder pressures and improved engine efficiency. However, it is important to note that excessive advancing of the timing can lead to engine knocking or pinging, which can cause damage. On the other hand, retarding the ignition timing can have the opposite effect. By delaying the spark, the air-fuel mixture has less time to burn, resulting in a less efficient combustion process. This can lead to an increase in fuel consumption as more fuel may be required to maintain the same level of power output. Additionally, retarding the timing can also cause a decrease in engine performance and power output. Furthermore, the ignition timing curve can vary depending on the engine's RPM. As RPM increases, the ignition timing must be advanced earlier to allow for the faster combustion process. This is especially important in high-performance engines, where precise ignition timing is critical for optimizing power and efficiency. In conclusion, the relationship between ignition timing and fuel consumption is intricate and multifaceted. Advancing or retarding ignition timing can impact torque, fuel consumption, and engine performance. However, it is essential to consider the various factors that influence this relationship, such as engine design, load conditions, and air-fuel ratio. By carefully tuning the ignition timing and air-fuel mixture, one can achieve optimal engine performance, fuel efficiency, and longevity. You may want to see also Ignition timing is a critical aspect of engine performance, and getting it right is essential for optimising engine power and efficiency. Ignition timing refers to the moment the spark plug fires during the compression stroke, igniting the air-fuel mixture in the combustion chamber. This process occurs just before the piston reaches the top dead centre (TDC) of its compression stroke. Advancing or retarding the ignition timing refers to adjusting the spark relative to the piston's position. Advancing the timing means the spark occurs earlier in the compression stroke, while retarding delays it. The ignition timing has a significant impact on engine performance and can be fine-tuned to increase power or fuel efficiency. Advancing the ignition timing increases an engine's high-end power while reducing low-end power. It also helps the engine run at peak power by overcoming the ignition delay. Conversely, retarding the timing reduces engine detonation or "knocking", which is spontaneous combustion inside the cylinders after the spark fires. For turbocharged or supercharged engines, retarding the timing can compensate for denser air and fuel mixtures, improving efficiency. The ideal ignition timing ensures the peak cylinder pressure occurs around 12 to 15 degrees after the piston reaches TDC. This maximises the mechanical advantage of the connecting rod and crankshaft, resulting in optimal torque and power output. Advancing the timing too much can cause "knocking" or "detonation", where the rapidly combusting mixture pushes against the piston during its compression stroke, potentially causing engine damage. On the other hand, retarding the timing too much results in lost power, overheating, high emissions, and unburned fuel. Modern engines use an engine control unit (ECU) to control ignition timing, adjusting it in real time based on the engine's RPM and load. Older engines, on the other hand, rely on mechanical distributors that use inertia and manifold vacuum to set the timing. Advancements in ignition timing control, such as electronic ignition systems and computer-controlled timing, have improved engine performance and fuel efficiency while reducing the need for manual adjustments. When tuning an engine, it is crucial to consider various factors that influence ignition timing, such as spark plug condition, engine temperature, intake pressure, and engine load. Adjustments to the engine, such as upgrades or changes in components, will also require corresponding changes to the ignition timing settings to ensure optimal performance and prevent damage. You may want to see also Advancing the ignition timing will generally increase torque and lean out the air-fuel mixture. However, ignition timing does not directly affect the air-fuel ratio. The ideal air-fuel ratio for a complete chemical reaction is roughly 14.7 parts air to 1 part fuel by mass. This is called the Stoichiometric Air to Fuel Ratio. If the air-fuel ratio is too rich, you will start to lose power and may foul the spark plugs and put fuel into the oil. If the air-fuel ratio is too lean, you will start to lose power and may eventually melt pistons and cause catastrophic engine failure.Fuel Filter Change: Essential for 2004 Tacoma Performance?

The impact of ignition timing on engine power

Replacing Your Fuel Cap: A Step-by-Step Guide for Beginners

The relationship between ignition timing and fuel consumption

Should You Replace a Single Fuel Injector?

The role of ignition timing in engine tuning

Muffler Modifications: Impacting Fuel Efficiency and Performance?

Frequently asked questions