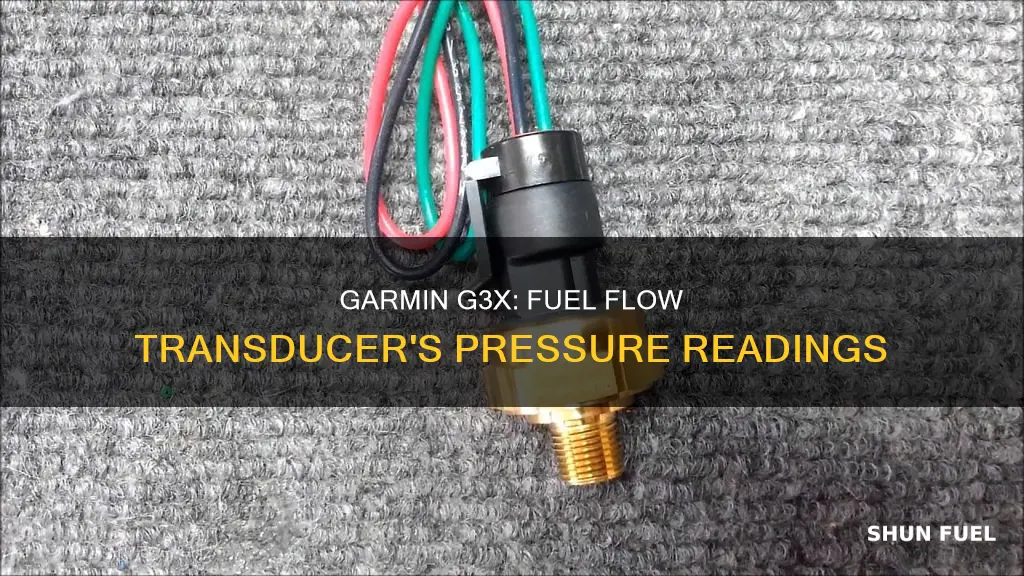

The Garmin G3X Touch is an aircraft flight display system that provides engine, fuel, and electrical information. The system includes a fuel flow transducer, which measures the rate of fuel flow. While the G3X Touch does not directly provide fuel pressure readings, it can display fuel pressure when paired with a compatible fuel pressure sensor. This is achieved by referencing the manifold pressure from the engine's Full Authority Digital Engine Control (FADEC) system. The fuel pressure reading can be further calibrated by applying an offset value, which may vary depending on factors such as altitude and atmospheric pressure.

| Characteristics | Values |

|---|---|

| Brand | Garmin |

| Model | G3X Touch |

| Purpose | Monitor engines and fuel |

| Compatibility | Most normally aspirated or turbocharged Lycoming/Continental 4- to 6-cylinder singles and twins, select single-engine turboprop aircraft, and single-engine piston aircraft |

| Display | Streamlined, intuitive user interface |

| Installation | Minimal or no panel modifications required |

| Fuel-related functions | Monitor fuel quantity and fuel flow to estimate how much fuel, range, and flight time remains |

| Fuel flow transducer compatibility | Aircraft with engine-driven fuel pumps & horsepower up to 350 HP |

| Fuel pressure sensor compatibility | Fuel-injected engines, carbureted engines |

| Fuel pressure sensor part number | 011-05783-20 |

| Fuel pressure sensor mounting threads | 1/8-27 NPTF |

| Fuel pressure sensor wire leads | 12 inch M22759/9-16 200 deg.C |

| Fuel pressure sensor psi | 75 psi (fuel-injected engines), 15 psi (carbureted engines) |

What You'll Learn

- The G3X fuel flow transducer is compatible with fuel-injected engines

- The transducer is also compatible with carbureted engines

- The transducer is suitable for aircraft with engine-driven fuel pumps

- The G3X system can be calibrated to provide accurate fuel pressure readings

- The calibration process involves setting an offset value for the entire range of the gauge

The G3X fuel flow transducer is compatible with fuel-injected engines

The G3X Touch can be combined with PFD and MFD capabilities, providing an "all-in-one" flight display solution. It also features customizable exceedance alerting and engine performance data logging, with both predefined and pilot-selectable alerts to help identify potential out-of-limit exceedances. The system can automatically log engine performance data for post-flight analysis, which can be wirelessly transmitted to a compatible mobile device or uploaded to flyGarmin.com.

The G3X fuel flow transducer is designed for aircraft with engine-driven fuel pumps and horsepower up to 350 HP. It has a 1/4" Female NPT fuel flow transducer and comes with a pre-wired mating connector with 12-inch M22759/9-16 200-degree C wire leads. The transducer has a mounting thread size of 1/8-27 NPTF.

The G3X fuel pressure sensor is specifically designed for fuel-injected engines and has a pressure capacity of 75 psi. It is important to note that if you are using a carbureted engine, you will need to purchase the 15 psi fuel pressure sensor instead.

The G3X system also includes a fuel pressure transducer with a pressure capacity of 15 psi, which is designed for Rotax 912 engines. This transducer is part of the G3X sensor kit, which also includes other components such as oil pressure transducers, manifold pressure transducers, thermocouples, and shunts.

Fuel Pressure Regulator Cost: What's the Price Range?

You may want to see also

The transducer is also compatible with carbureted engines

The Garmin G3X fuel flow transducer is compatible with carbureted engines. The transducer is designed for use in aircraft with engine-driven fuel pumps and a horsepower of up to 350 HP. It is a powered pressure transducer that provides fuel pressure readings for carbureted engines.

The G3X fuel flow transducer is part of the Garmin G3X system, which offers a range of Engine Indication System (EIS) solutions. The EIS solutions provide engine and fuel information with enhanced precision, helping to reduce pilot workload and improve engine and fuel management. The G3X system includes the GI 275 EIS, EIS TXi, and G3X Touch™ flight displays, which combine EIS information with primary flight display (PFD) and multi-function display (MFD) capabilities.

The G3X fuel flow transducer is available in different models to accommodate different types of engines. For carbureted engines, the 15 psi fuel pressure sensor is recommended. This transducer has mounting threads and comes with a prewired mating connector with wire leads. It is important to select the appropriate sensor for the specific engine type to ensure accurate fuel pressure readings.

The G3X fuel flow transducer is just one component of the comprehensive G3X system, which offers a range of features and benefits to enhance the flight experience and improve overall engine and fuel management.

Changing Fuel Pressure Regulator on LB7 Duramax: Step-by-Step Guide

You may want to see also

The transducer is suitable for aircraft with engine-driven fuel pumps

The Garmin G3X fuel flow transducer is suitable for aircraft with engine-driven fuel pumps and a horsepower of up to 350 HP. The transducer is compatible with the Garmin G3X system and is designed to provide fuel flow data to the system.

The G3X fuel flow transducer is a standalone solution that can be easily integrated into the aircraft's existing system. It connects to the fuel line and measures the fuel flow rate, providing accurate and reliable data to the G3X system. This data is then used to estimate the amount of fuel remaining, range, and flight time, assisting pilots in making informed decisions and improving overall fuel management.

The transducer is designed to be versatile and adaptable to different aircraft types. It comes with a standard 1/4" Female NPT fitting, making it compatible with a wide range of aircraft fuel systems. Additionally, the transducer has a compact design, ensuring a seamless and straightforward installation process without requiring significant modifications to the aircraft's panel.

The G3X fuel flow transducer is a reliable and accurate solution for aircraft with engine-driven fuel pumps. It provides critical fuel flow data, helping pilots make informed decisions, improve fuel efficiency, and ensure a safe flight. This transducer is a valuable tool for any pilot or aircraft owner looking to enhance their fuel management system and overall flight experience.

Replacing Fuel Tank Pressure Sensor in Chevy Silverado: Step-by-Step Guide

You may want to see also

The G3X system can be calibrated to provide accurate fuel pressure readings

The calibration process involves adjusting the K-factor, which is a calibration factor used to correct the fuel flow rate. The K-factor can be adjusted through the calibration menu, which is accessible through the G3X system. By adjusting the K-factor, the G3X system can be calibrated to provide accurate fuel pressure readings. This is particularly useful when the system is installed in aircraft with the Rotax 912is Engine, as the Rotax engine does not have an actual fuel flow transducer and relies on "theoretical" data based on fuel injector pulses and pulse width.

In addition to the K-factor calibration, the G3X system also allows for fuel pressure sensor calibration. This calibration process involves setting the "Pressure Reference" to "Manifold Pressure" and then calibrating the system by adjusting an offset value. The offset value is specific to the aircraft and takes into account factors such as altitude and atmospheric pressure changes. By properly calibrating the fuel pressure sensor, the G3X system can provide accurate fuel pressure readings.

It is important to note that the calibration process may vary depending on the specific G3X system and aircraft configuration. Therefore, it is always recommended to refer to the manufacturer's instructions and seek expert advice when performing any calibrations or adjustments to the system.

Vacuum and Pressure: Fuel Tank's Unseen Forces

You may want to see also

The calibration process involves setting an offset value for the entire range of the gauge

The calibration process for setting the fuel pressure on the Garmin G3X involves determining an offset value that accounts for the difference between the uncalibrated and calibrated fuel pressure readings. This offset value is specific to the aircraft and remains constant across the entire range of the gauge.

To begin the calibration process, access the calibration screen on the G3X GDU 460 and ensure the engine is not running. Turn on the fuel pump and adjust the offset number until the uncalibrated pressure matches the calibrated pressure. This initial setting will depend on the current altitude and atmospheric conditions. For instance, at sea level, the offset value is typically around 14.5 PSI, while at higher altitudes, an offset of 12.5 PSI may be more appropriate.

It is important to note that the G3X's ability to compensate for changes in altitude and atmospheric pressure is unclear. Therefore, the calibration process may need adjustments to account for these factors accurately. Additionally, the fuel pressure sender model and the specific aircraft engine may influence the calibration process.

Always refer to official documentation and guidelines for calibration procedures and ensure that any adjustments are made by qualified individuals to ensure safety and accuracy.

Best Places to Buy AC Delco Fuel Pressure Sensors

You may want to see also

Frequently asked questions

Yes, the Garmin G3X fuel flow transducer provides fuel pressure readings.

To set the fuel pressure on the Garmin G3X, you need to change the "Pressure Reference" to "Manifold Pressure" and then calibrate it. The calibration procedure should come from Rotax.

The equation for fuel pressure is: fuel pressure + offset - manifold air pressure.

The offset value is likely airframe-specific and will depend on your altitude and atmospheric pressure.