If your car is running rough or using gas less efficiently, it may be time to test its fuel pressure. Testing fuel pressure can help identify issues with low fuel pressure, faulty fuel pressure regulators, leaking injectors, fuel leaks, or clogged fuel filters. While you can buy a fuel pressure tester, some automotive stores also rent them out. For example, AutoZone, Advance Auto Parts, and O'Reilly Auto Parts all offer rental services for fuel pressure testers and other automotive maintenance and repair tools.

| Characteristics | Values |

|---|---|

| Name | Innova Fuel Injection Pressure Tester Kit 3640 |

| Dial face | 2 1/2" |

| Dial face scale | 0-100 PSI |

| Hose length | 16" |

| Hose material | Brass |

| Hose type | Gauge |

| Bleed-off hose length | 6-foot |

| Test adapters | Ford, GM, Chrysler, "tee" adapter for import vehicles |

What You'll Learn

How to use a fuel pressure tester

A fuel pressure tester can help you diagnose whether your engine problems are fuel-related. An engine needs four things to run: air, fuel, spark, and compression.

Step 1: Determine Your Fuel Type

Before buying a fuel pressure tester, you need to determine what type you need. If your vehicle is carbureted, you will need a tester meant for it. Most vehicles, however, are fuel-injected.

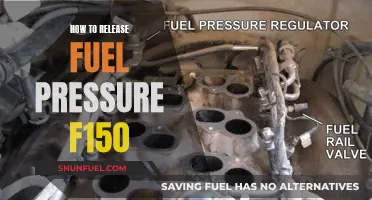

Step 2: Park & Inspect the Vacuum Line

Park your vehicle on flat ground and turn the engine off. You can also engage your emergency brake for safety. Open the hood of your car to locate the vacuum line. The vacuum line will be attached to the fuel pressure regulator. Remove the line from the fuel pressure regulator. If there is fuel observed dripping from or in the line, it is a clear sign that your regulator has failed. After inspecting the vacuum line, reconnect it to the fuel pressure regulator.

Step 3: Connect Your Fuel Pressure Gauge

With your fuel pressure regulator and vacuum line reconnected, get your fuel pressure gauge. Most vehicles now include a test port for the gauge. If not, you will need a fuel filter adapter. Remove the protective cap from the test port and connect your fuel gauge line.

Step 4: First Test (Ignition On)

Turn the ignition key to the "ON" position. If you have a direct port inject system, or DPI, the gauge should display a reading between 45 psi and 58 psi. For throttle body inject (TBI) systems, it should read between 13 psi and 17 psi. Should your gauge reflect these readings, it means your pump and electrical portion of the fuel system are working properly.

Note: If the gauge does not react, you will need to check the pump relay and fuse. These are contained in the power distribution center. It may also indicate a fuel pump power feed wire disconnect. Using your service manual, locate the correct wire in your wiring harness. Ground this wire and test it. Have a helper turn the engine over, which will give you one of two outcomes. If the probed light illuminates and your pressure gauge still does not show a reading, the fuel pump has failed. If the light does not illuminate and the gauge remains still, the fuel pump relay or wiring circuit has failed.

Step 5: Second Test (Run the Engine)

With the engine running, the fuel pressure gauge should show a drop of about 5 psi. If you rev your engine, the pressure should then jump about 5 psi. This verifies that the fuel pressure regulator is working as it should. If not, check if the vacuum line was reattached correctly. If the line was properly reattached, then the lack of appropriate dips and spikes in your gauge readout indicates a failed regulator.

Step 6: Third Test (Operational Loads)

When your engine is engaged and you are at a constant rate of speed, it is referred to as being "under load". Ideally, the gauge will remain the same as when you started the engine. However, a slight drop is also acceptable. If the fuel pressure does drop a bit while under load or idling, the likely culprit is a clogged fuel filter. If the drop is large, the fuel pump has likely failed.

Step 7: Remove the Fuel Pressure Gauge

When you have finished your testing, it is time to remove the fuel pressure gauge. Note that some fuel will likely leak out during this step. Grab a shop towel and place or hold it under the test port. Loosen and remove the pressure hose. After that, replace the protective cap over the test port. Inspect the area for any leaks before closing the hood.

Step 8: Refer to the Manual

Most vehicle service manuals list the specific pressure, or pressure ranges, your car should hit during each of the pressure tests. Compare your results to these industry standards for your specific make and model.

When to See a Mechanic

Not all fixes are easy. For some issues, it may be best to take your vehicle to a mechanic after experiencing any negative test results. If you are unsure of how to test your fuel pressure or do not feel comfortable doing so, ask a reputable local mechanic to do it for you.

Fuel Filter Clogging: Impact on Fuel Pressure and Performance

You may want to see also

How to test fuel pressure

Testing fuel pressure can help you diagnose starting or running issues with your car. Before you begin, note that fuel vapours are highly flammable, so ensure you perform these steps in a well-ventilated area with a fire extinguisher nearby.

Step 1: Check Your Fuel Tank

This may sound obvious, but the first step is to check that there is actually gas in your tank. Do not trust the fuel gauge – add at least two gallons to the tank and try to start your car again. If it starts, check the fuel gauge for internal failure and replace it if necessary. If the new gauge shows the same high fuel level, the issue is likely a failed fuel sending unit in the gas tank.

Step 2: Check Your Fuel Pump

If your fuel tank is not the issue, the next step is to verify that your fuel pump works. Head to the back of your car, near the fuel tank, and ask an assistant to turn the ignition switch to "On". You should hear a two-second whir, hum, or series of rapid clicks as the fuel pump pressurises the fuel line to the engine. If you don't hear this, your pump is either not getting power or it has failed. Check the fuel pump fuse and relay. If both are fine, check the wiring to the pump. If voltage is present when turned to "On", your pump has failed and you will need to swap it out.

Step 3: Connect a Fuel Pressure Tester

Pop the hood and find the Schrader valve fitting on the fuel rail. Remove the Schrader valve cap and attach the appropriate fuel pressure tester fitting, ensuring that it is leakproof. Turn the ignition to "On", not "Start", and check the psi reading. If the psi reading drops, this indicates a leak in the system. If the pressure drops over 10 minutes, this means there is a leak in the fuel system.

Step 4: Start Your Engine

Start your engine and let it idle. You should see a steady fuel pressure, within a few psi of the recommended pressure for your vehicle. Once the engine is warmed up, slowly rev the engine and check that the pressure rises with the RPMs. If your fuel pressure holds steady and is within the recommended pressure, your problem does not seem to be fuel-related.

Understanding Fuel Pressure Readings

Zero fuel pressure means your pump is dead or not getting power. Low fuel pressure could be caused by a clogged fuel filter or a failing pump. High fuel pressure could be caused by a clogged or kinked fuel return line, a bad fuel pump driver module, or a faulty fuel pressure regulator.

Locating the Fuel Pressure Sensor in a 99 GMC Safari

You may want to see also

Signs of low fuel pressure

A fuel pressure tester is a simple design consisting of a gauge attached to a fuel hose and multiple fittings. The various fittings connect to the fuel system of nearly any vehicle. When connected and the fuel system is pressurised, the tester displays the pressure in psi on a large gauge visible from inside the vehicle.

While zero fuel pressure means the engine won't run, low pressure sometimes allows engine operation with issues. Here are some signs of low fuel pressure:

- A slow start-up

- Low performance

- Misfires

- Stalling

Low fuel pressure could be caused by a clogged fuel filter or a failing pump. If it is a serviceable type filter, it is recommended to change the fuel filter. It could also be caused by improper tank venting, an emissions issue caused by a loose gas cap. Check that the cap gasket isn't damaged, and tighten it until it clicks.

Another cause of low fuel pressure could be the fuel injectors. If a fuel injector gets stuck open, it allows pressurised fuel meant for another cylinder to leak into the cylinder of the stuck injector and cause low fuel pressure. You could start by pulling all of your spark plugs and looking for the one with a different-looking electrode than the others. In this case, it may appear cleaner as the extra fuel not being burnt in the cylinder may be washing dirt from the spark plug.

Fuel Pressure and Engine Knock: Is There a Link?

You may want to see also

Signs of high fuel pressure

While it is not clear whether Advance Auto rents fuel pressure testers, there are several signs that can indicate high fuel pressure in your vehicle.

High fuel pressure means that the air-to-fuel ratio is off-kilter, leading to an imbalance of fuel pressure. This can cause both short-term and long-term damage to vehicles. Here are some common symptoms to look out for:

- Your engine is running rough or rich, which means there is too much fuel and not enough air. This can result in poor gas mileage and black smoke from the exhaust.

- You may notice a fuel smell coming from the exhaust.

- Constant refuelling due to low fuel economy.

- Poor engine performance.

- Blackened or wet spark plugs with fuel.

- Restrictions in the return line.

- An overheating catalytic converter.

- Excessive fuel consumption.

- Rough idle.

If you suspect high fuel pressure, it is best to take your vehicle to a trusted mechanic or auto repair shop for diagnosis and repair to avoid further damage.

Fuel Pressure Issues in Can-Am 1000: Troubleshooting and Fixes

You may want to see also

How to connect a fuel pressure tester

Note: Fuel vapours are highly flammable, so ensure you perform these steps in a well-ventilated area with a fire extinguisher nearby.

- Pop the hood with an entirely cold engine.

- Find a Schrader valve fitting on the fuel rail. Most vehicles will have them, although they may be hidden under a fuel rail cover or other plastic engine cover.

- Remove the Schrader valve cap.

- Attach the appropriate fuel pressure tester fitting. Ensure it threads on properly for a leak-proof fit.

- Turn the ignition to "on", not "start".

- Check the psi reading. Wait and watch for a psi drop, which indicates a leak in the system. If the reading is the same after 5 to 10 minutes, the system is holding pressure well.

- If the fuel pressure drops over 10 minutes, this indicates a leak in the fuel system. Look for drips underneath to help locate the source of the leak. It could also be leaking internally from a bad fuel injector.

- Start your engine and let it idle. You should see a steady fuel pressure, within a few psi of the recommended pressure.

- Once the engine is warmed up, give the engine a slow rev, making sure the pressure rises with the RPMs.

If your fuel pressure holds steady, rises with engine speed, and is at the recommended pressure, your engine problem does not seem fuel-related.

Replacing the Fuel Pressure Regulator in a 1992 GMC Sonoma

You may want to see also

Frequently asked questions

Yes, Advance Auto Parts offers fuel pressure testers for rent. The Innova 3640 Fuel Injection Pressure Tester has a large, easy-to-read 2 1/2" dial face with a 0-100 PSI scale. It helps identify and diagnose common fuel system issues.

A fuel pressure tester consists of a gauge attached to a fuel hose with multiple fittings. The fittings connect to the fuel system of nearly any vehicle. When connected and the fuel system is pressurized, the tester displays the pressure in psi on the gauge, allowing you to verify fuel pressure from the driver's seat.

Good fuel pressure depends on the engine. Older throttle-body injected systems may need as little as 10 psi, while multi-port injection can see as high as 60 psi. Check your repair manual for the specific fuel pressure requirements of your engine.