The car fuel pump is a critical component of a vehicle's fuel system, responsible for delivering gasoline from the tank to the engine. It is a vital part of the engine's operation, as it ensures a steady supply of fuel to the engine's cylinders. However, the question arises: does the fuel pump run continuously while the car is on? Understanding the operation of the fuel pump is essential for car owners to know how their vehicles function and to identify potential issues.

| Characteristics | Values |

|---|---|

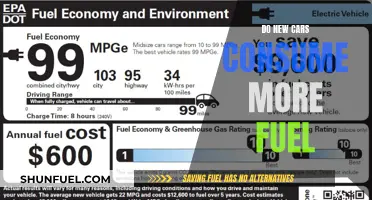

| Continuous Operation | Yes, the fuel pump runs continuously while the engine is running to ensure a steady supply of fuel. |

| Engine Start-Up | The pump engages when the engine is started and remains active until the engine is turned off. |

| Fuel Pressure | Maintains consistent fuel pressure to ensure efficient combustion and engine performance. |

| Pump Location | Often located inside the fuel tank or in close proximity to it for efficient fuel delivery. |

| Power Source | Powered by the vehicle's electrical system, typically drawing power from the battery. |

| Wear and Tear | Continuous operation can lead to increased wear and tear, requiring regular maintenance and potential replacement. |

| Fault Detection | Malfunctioning pumps can cause engine misfires, reduced power, or difficulty starting, indicating the need for inspection. |

| Efficiency | Running all the time ensures optimal fuel delivery, improving engine efficiency and performance. |

| Safety | Continuous operation helps prevent fuel starvation, reducing the risk of engine stall or damage. |

What You'll Learn

- Continuous Operation: Does the fuel pump run continuously when the engine is off

- Idle Performance: How does the fuel pump perform during engine idling

- Fuel Pressure Regulation: How does the fuel pump regulate pressure when the engine is running

- Fuel Pump Relay: What is the role of the fuel pump relay

- Fuel Pump Failure: What are the signs of fuel pump failure

Continuous Operation: Does the fuel pump run continuously when the engine is off?

The fuel pump in a car is a critical component responsible for delivering fuel from the tank to the engine. It operates continuously when the engine is running, ensuring a steady supply of fuel to meet the engine's demands. However, the question of whether the fuel pump continues to run when the engine is off is an important one, as it can impact fuel efficiency and overall vehicle performance.

When the engine is off, the fuel pump's operation is not solely dependent on the engine's electrical system. Instead, it is often powered by a separate electrical circuit designed specifically for this purpose. This circuit is typically activated when the ignition is turned off, ensuring that the fuel pump remains operational even when the engine is not running. The primary reason for this continuous operation is to maintain a consistent fuel pressure in the system, which is crucial for proper engine operation when it is started again.

The fuel pump's continuous operation when the engine is off is a safety feature and a practical design choice. It ensures that the fuel system is always ready for the engine to start, providing a reliable supply of fuel. This is particularly important in modern vehicles, where electronic fuel injection systems require precise fuel pressure control for optimal performance. By keeping the fuel pump active, the vehicle's fuel system remains in a state of readiness, minimizing the time it takes to start the engine and reducing the risk of fuel-related starting issues.

Additionally, the continuous operation of the fuel pump when the engine is off can contribute to better fuel efficiency. When the engine is not running, the fuel pump can maintain a steady flow of fuel, preventing air bubbles from forming in the lines. This ensures that the fuel system is always prepared for the engine's restart, reducing the time and effort required for the engine to reach its optimal operating state.

In summary, the fuel pump in a car does not run continuously when the engine is off, but it is designed to operate in a specific electrical circuit that remains active during this period. This continuous operation is essential for maintaining fuel pressure, ensuring a reliable engine start, and potentially improving fuel efficiency. Understanding this aspect of the fuel pump's functionality is vital for vehicle owners and mechanics alike, as it highlights the importance of proper electrical system maintenance and the role of the fuel pump in overall vehicle performance.

Fuel Injector Cleaner: Safe for Modern Engines?

You may want to see also

Idle Performance: How does the fuel pump perform during engine idling?

The fuel pump in a car is a critical component that ensures a steady supply of fuel to the engine, even during idling. When the engine is idling, it operates at a lower speed and requires a consistent fuel flow to maintain its operation. This is where the fuel pump's role becomes crucial.

During engine idling, the fuel pump operates at a reduced speed compared to when the engine is running at full load. This is because the engine's demand for fuel is lower, and the pump needs to provide a steady but reduced flow rate. The pump's performance during idling is designed to meet the engine's specific requirements at this lower speed. It ensures that the fuel is delivered efficiently to the engine's carburetor or fuel injection system, allowing for smooth and controlled operation.

The idle performance of the fuel pump is essential for several reasons. Firstly, it helps maintain the engine's temperature. When idling, the engine's temperature is lower, and the fuel pump's operation ensures that the fuel is delivered at an appropriate rate to support the engine's cooling process. Secondly, it contributes to the engine's emissions control. During idling, the engine produces higher emissions, and the fuel pump's precise control over fuel flow helps optimize combustion, reducing the release of harmful pollutants.

Additionally, the fuel pump's idle performance is vital for engine start-up. When the engine is cold, it requires a higher fuel flow rate to start the combustion process. The pump's ability to deliver fuel efficiently during idling ensures that the engine can start smoothly and quickly. This is particularly important in cold climates or when the vehicle has been stationary for an extended period.

In summary, the fuel pump's performance during engine idling is a critical aspect of its overall function. It ensures a steady fuel supply, supports engine temperature control, contributes to emissions reduction, and facilitates smooth engine start-up. Understanding the pump's behavior during idling is essential for optimizing engine performance and maintaining the vehicle's overall health.

Mastering Idle Control: Adjusting Fuel Injection for Optimal Performance

You may want to see also

Fuel Pressure Regulation: How does the fuel pump regulate pressure when the engine is running?

The fuel pump plays a critical role in ensuring that the engine receives the correct amount of fuel at the right pressure to operate efficiently and effectively. When the engine is running, the fuel pump's primary function is to regulate the pressure of the fuel, which is essential for proper engine performance. Here's a detailed explanation of how this regulation process works:

Fuel Pressure Regulation Mechanism:

The fuel pump is designed to maintain a consistent and precise fuel pressure within the engine's fuel system. When the engine is running, the pump operates continuously to supply fuel to the injectors or carburetor. The regulation process involves a few key components. Firstly, the pump is connected to a pressure regulator, which is typically a small solenoid-operated valve. This valve is designed to control the flow of fuel from the pump to the engine. When the engine is idling or running at lower speeds, the pressure regulator remains closed, allowing fuel to flow freely from the pump to the engine.

Pressure Control:

As the engine speed increases, the demand for fuel also rises. To meet this demand, the fuel pump activates a higher flow rate, providing more fuel to the engine. The pressure regulator senses this increased flow and opens slightly, allowing a controlled amount of fuel to pass through. This regulated flow ensures that the fuel pressure remains stable and within the optimal range required by the engine. The pump's ability to adjust its output based on engine speed is crucial for efficient performance and fuel economy.

Feedback Loop:

Modern fuel systems often employ a feedback loop to fine-tune pressure regulation. This loop involves pressure sensors that monitor the fuel pressure and provide feedback to the engine's electronic control unit (ECU). The ECU then adjusts the pump's operation accordingly. If the pressure is too high, the pump may reduce its output, and if it's too low, the pump can increase its flow rate. This real-time adjustment ensures that the fuel pressure is always within the desired range, optimizing engine performance and fuel efficiency.

Continuous Operation:

While the fuel pump regulates pressure based on engine demand, it does not run continuously in the sense that it is always active. The pump's operation is controlled by the engine's needs. When the engine is off, the pump is typically deactivated to conserve power and prevent unnecessary fuel consumption. However, when the engine starts, the pump quickly activates to supply fuel and maintain the required pressure for smooth operation.

In summary, the fuel pump's role in pressure regulation is vital for engine performance and efficiency. By adjusting its output based on engine speed and demand, the pump ensures that the fuel pressure remains optimal, providing the engine with the necessary power and fuel economy. This regulation process is a critical aspect of modern fuel injection systems, contributing to the overall reliability and responsiveness of a vehicle's engine.

Is Fuel Stabilizer a Must-Have for Your Car?

You may want to see also

Fuel Pump Relay: What is the role of the fuel pump relay?

The fuel pump relay is a crucial component in a vehicle's fuel system, often overlooked but essential for the proper functioning of the engine. Its primary role is to control the operation of the fuel pump, ensuring that the engine receives the required amount of fuel for optimal performance. This relay is designed to manage the power supply to the fuel pump, which is responsible for delivering fuel from the tank to the engine's injectors or carburetor.

In modern vehicles, the fuel pump relay is typically an electronic device that acts as an intermediary between the engine control unit (ECU) and the fuel pump. When the engine is started, the ECU sends a signal to the relay, which then activates the fuel pump. This process ensures that the fuel pump operates only when needed, conserving energy and preventing unnecessary wear and tear on the pump. By controlling the power supply, the relay also protects the fuel pump from potential damage caused by excessive current or voltage.

The function of the fuel pump relay is to manage the fuel pump's operation in two main ways. Firstly, it regulates the power supply, ensuring the pump runs at the correct voltage and current levels. This is crucial as an overpowered fuel pump can lead to excessive fuel pressure, potentially causing engine damage. Secondly, the relay provides a time delay, allowing the pump to prime the fuel system before the engine starts. This delay ensures that the engine receives a steady supply of fuel, promoting efficient combustion and smooth operation.

In older vehicle models, the fuel pump relay might be a simpler mechanical switch that engages the pump when the ignition is turned on. However, in newer cars, the relay is often an integral part of the fuel pump module, combined with other control functions. This design evolution has improved reliability and efficiency, as the relay now includes additional safety features and can manage more complex operations.

Understanding the role of the fuel pump relay is essential for vehicle owners and mechanics alike. Proper maintenance and timely replacement of this component can prevent fuel-related issues and ensure the engine operates efficiently. Regular checks and testing of the relay can help identify potential problems, such as faulty wiring or a failing relay, which could lead to fuel pump failure and subsequent engine performance issues.

Fuel Door Placement: A Global Standard for Car Safety and Convenience

You may want to see also

Fuel Pump Failure: What are the signs of fuel pump failure?

The fuel pump in a car is a critical component responsible for delivering fuel from the tank to the engine. It operates continuously while the engine is running, ensuring a steady supply of fuel for combustion. However, like any mechanical part, the fuel pump can experience wear and tear over time, leading to potential failure. Recognizing the signs of fuel pump failure is essential for prompt maintenance and repair to prevent further issues.

One of the most common indicators of fuel pump failure is a decrease in engine performance. If you notice that your car's engine is running roughly, losing power, or stalling, it could be a sign that the fuel pump is not functioning optimally. This is because a failing pump may not be able to deliver the required amount of fuel to the engine, resulting in poor performance. You might also experience a noticeable drop in fuel efficiency, as the engine struggles to run efficiently with insufficient fuel supply.

Another sign to look out for is difficulty starting the engine. When the fuel pump fails, the engine may not receive enough fuel to start, leading to frequent dead battery situations or a car that won't start at all. This is often accompanied by a clicking sound from the fuel pump when you turn the key or press the start button, indicating that it is not priming the fuel properly. In some cases, you might hear a whining or roaring sound from the fuel pump, suggesting that it is working harder than usual to try and deliver fuel, but ultimately failing.

Additionally, fuel pump failure can manifest as strange noises coming from the engine compartment. A failing pump may produce a high-pitched whine or a humming sound, especially when the engine is idling or during acceleration. This is due to the pump working harder to push fuel through a restricted or damaged passage. If you notice any unusual sounds, especially those that change with engine load, it's crucial to inspect the fuel pump immediately.

Lastly, a visual inspection can provide valuable clues. Check for any signs of corrosion or damage around the fuel pump, especially if you've noticed leaks or spills around the fuel tank. Over time, fuel can corrode the pump and its internal components, leading to failure. If you suspect fuel pump failure, it is advisable to have it professionally diagnosed and replaced to ensure your vehicle's reliability and performance.

Stick Shift Efficiency: Fuel Emissions Compared to Automatic Transmissions

You may want to see also

Frequently asked questions

No, the fuel pump does not run all the time. It operates only when the engine is running and requires fuel. When the engine is off, the pump is deactivated to conserve power and extend the battery life.

The fuel pump is an essential component of the fuel injection system. It is responsible for delivering fuel from the fuel tank to the engine's carburetor or fuel injectors. When the engine is started, the pump activates and pressurizes the fuel, ensuring a steady supply of gasoline for combustion.

Yes, if the fuel pump operates continuously, it can lead to several problems. Overheating, excessive wear, and potential failure are risks associated with constant operation. It is designed to run only when necessary, and prolonged activation may indicate a potential issue with the fuel system.

Yes, it is normal for the fuel pump to run when the car is idling. During idling, the engine requires a small amount of fuel to maintain operation. The pump ensures a consistent fuel supply, allowing the engine to idle smoothly.

You can perform a few simple checks to assess the fuel pump's health. Start by ensuring the fuel tank is full and the engine is running. Listen for any unusual noises, and check for leaks around the fuel lines. If you suspect an issue, it is best to consult a professional mechanic for a thorough inspection.