Thread seal tape, commonly known as thread seal tape or pipe dope, is a crucial component in plumbing and automotive applications. It is used to ensure a tight and leak-free connection between threads on pipes, fittings, and other components. However, when it comes to fuel lines, a specific type of thread seal is required to meet the unique demands of the fuel system. This paragraph will explore the availability and importance of thread seal tape specifically designed for fuel lines, addressing the question of whether such a product exists and why it is essential for maintaining the integrity of the fuel system.

| Characteristics | Values |

|---|---|

| Availability | Yes, thread seal tape and compounds are available for fuel lines |

| Compatibility | Specific products are designed for fuel lines, often made of rubber or plastic |

| Material | Silicone, butyl, or other rubber-based compounds |

| Application | Thread sealing for fuel lines in engines, often used in automotive repairs |

| Function | Creates a tight seal to prevent fuel leaks |

| Advantages | Easy to apply, provides a reliable seal, and is resistant to fuel chemicals |

| Disadvantages | May not be as strong as welding or bonding methods |

| Usage | Common in DIY repairs and maintenance |

What You'll Learn

- Materials Compatibility: Ensure thread seal tape is compatible with fuel line materials to prevent leaks

- Resistance to Fuel: Choose thread seal tape resistant to fuel chemicals for long-lasting protection

- Temperature Tolerance: Select tape that can withstand fuel line temperatures without degradation

- Flexibility: Opt for flexible thread seal tape to accommodate fuel line movement without cracking

- Installation Techniques: Learn proper installation methods for effective thread sealing on fuel lines

Materials Compatibility: Ensure thread seal tape is compatible with fuel line materials to prevent leaks

When it comes to ensuring a secure and leak-free connection for fuel lines, thread seal tape is an essential component. However, it's crucial to understand the importance of materials compatibility to avoid potential issues. The primary goal is to prevent leaks, which can be detrimental to the performance and safety of a vehicle's fuel system.

The compatibility of thread seal tape with the materials used in fuel lines is a critical factor. Fuel lines are typically made from various materials such as rubber, plastic, or metal. Each material has unique properties and requires specific sealing techniques. For instance, rubber fuel lines are commonly used due to their flexibility and durability, but they may not be compatible with all types of thread seal tapes. Some tapes can cause degradation or hardening of the rubber over time, leading to potential leaks. Therefore, it is imperative to choose the right thread seal tape that is specifically designed for the material of the fuel line.

To ensure compatibility, it is recommended to consult the manufacturer's guidelines or specifications for the fuel lines. These guidelines often provide information on the recommended thread seal tapes or adhesives to use. Using the correct product ensures that the tape adheres well to the fuel line material, creating a tight seal without compromising the integrity of the line. This is especially important in high-pressure fuel systems where leaks can lead to engine misfires, reduced performance, and potential safety hazards.

In addition to compatibility, the application process is another critical aspect. Proper application techniques ensure that the thread seal tape is applied evenly and securely. This includes cleaning the threads to remove any dirt or debris, applying the tape in a continuous and even layer, and ensuring that the tape is tightly wound around the threads. Following the manufacturer's instructions for the specific tape being used will guarantee the best results.

In summary, when dealing with thread seal tape for fuel lines, materials compatibility is key. Choosing the right tape that is compatible with the fuel line material will prevent leaks and ensure the long-term reliability of the fuel system. Always refer to the manufacturer's recommendations and guidelines to make informed decisions and maintain the vehicle's performance and safety standards.

Maximizing Fuel Efficiency: The Role of Return Lines in Pumps

You may want to see also

Resistance to Fuel: Choose thread seal tape resistant to fuel chemicals for long-lasting protection

When it comes to ensuring the integrity of fuel lines, choosing the right thread seal tape is crucial. The primary concern here is the resistance to fuel chemicals, as these lines carry a highly corrosive and potentially damaging substance. Fuel contains various additives and chemicals that can erode traditional thread seal tapes over time, leading to leaks and potential engine damage. Therefore, selecting a tape specifically designed to withstand these fuel-related challenges is essential.

The market offers thread seal tapes engineered with materials that provide exceptional resistance to fuel chemicals. These tapes are typically made from compounds that create a robust, protective barrier around the threads of the fuel line. This barrier not only prevents fuel from seeping through but also guards against the corrosive effects of the fuel's additives. By choosing such a tape, you ensure that the fuel lines remain sealed tightly, maintaining the engine's performance and longevity.

One key aspect to consider is the temperature range in which the fuel lines operate. Fuel can vary in temperature depending on the climate and engine usage. Therefore, the thread seal tape should be compatible with these temperature fluctuations to ensure its effectiveness throughout the year. Look for tapes that offer flexibility and stability across a wide temperature range, ensuring they can adapt to the varying conditions without compromising their sealing properties.

Additionally, the ease of application is a practical consideration. Thread seal tapes should be simple to apply, ensuring a quick and efficient sealing process. This is particularly important in automotive repair scenarios where time is often a critical factor. A tape that is easy to wrap around the threads and provides a secure seal without requiring excessive force or multiple layers will be a preferred choice for many mechanics.

In summary, when dealing with fuel lines, it is imperative to select thread seal tape that offers resistance to fuel chemicals. This ensures the tape's longevity and the overall protection of the fuel lines. By considering the tape's resistance to fuel, temperature adaptability, and ease of application, you can make an informed decision, ensuring a reliable and long-lasting seal for your fuel lines. This approach contributes to the overall maintenance and performance of your vehicle's fuel system.

Mastering Fuel Line Maintenance: Spring Decoupling Tool Techniques

You may want to see also

Temperature Tolerance: Select tape that can withstand fuel line temperatures without degradation

When it comes to fuel lines, ensuring a secure and reliable connection is crucial for optimal engine performance and safety. One effective method to achieve this is by using thread seal tape, a specialized sealing solution designed to withstand the unique challenges of fuel line installations. This tape is engineered to provide a robust barrier against fuel leakage, ensuring that your engine operates efficiently without the risk of fuel seeping into unwanted areas.

The primary consideration when selecting thread seal tape for fuel lines is temperature tolerance. Fuel lines are exposed to varying temperatures, especially in automotive applications, where engines can operate under diverse climatic conditions. Extreme temperatures can cause degradation of the tape, leading to potential fuel leaks and engine issues. Therefore, it is imperative to choose a tape that can withstand these temperature fluctuations without compromising its integrity.

Look for thread seal tapes specifically formulated for fuel line applications. These tapes are typically made from materials that offer excellent resistance to heat and cold. For instance, some tapes are constructed with a blend of synthetic rubber and plasticizers, ensuring flexibility and durability across a wide temperature range. This composition allows the tape to maintain its sealing properties even when exposed to the high temperatures generated by an engine or the low temperatures of cold climates.

Additionally, consider the operating temperature range of your fuel lines. Different engines and fuel systems have specific temperature requirements. For instance, high-performance racing engines may operate at much higher temperatures than standard vehicles. Therefore, selecting a thread seal tape with a temperature rating that exceeds your fuel line's operating range is essential to ensure long-term reliability.

In summary, when dealing with fuel lines, temperature tolerance is a critical factor in selecting the right thread seal tape. Opt for tapes specifically designed for fuel line applications, ensuring they can withstand the temperature extremes your engine encounters. By choosing a tape with excellent temperature resistance, you can guarantee a secure and leak-free fuel line connection, contributing to the overall performance and longevity of your vehicle's fuel system.

Optimizing Performance: Choosing the Right Fuel Line for Your 3/8 ID Engine

You may want to see also

Flexibility: Opt for flexible thread seal tape to accommodate fuel line movement without cracking

When it comes to ensuring a secure and leak-free connection for fuel lines, the choice of thread seal tape is crucial. One of the key considerations is flexibility, especially in the context of fuel lines, which can experience movement and vibration during the operation of a vehicle. This is where flexible thread seal tape comes into play, offering a range of benefits that make it an ideal choice for this application.

Flexible thread seal tape is designed to accommodate the natural movement and expansion of fuel lines without compromising its sealing properties. Unlike traditional thread seal tapes, which may become brittle and crack over time, flexible options are crafted from materials that retain their pliability even in the face of mechanical stress. This is particularly important in fuel systems, where vibrations from the engine and temperature fluctuations can cause fuel lines to shift or expand.

The flexibility of these tapes allows them to conform to the unique shape and movement of fuel lines, ensuring a tight and reliable seal. This is especially critical in high-pressure fuel systems, where any compromise in the seal could lead to fuel leaks, potential engine damage, and safety hazards. By choosing a flexible thread seal tape, you are selecting a product that can adapt to the dynamic nature of fuel lines, providing a long-lasting and secure connection.

Furthermore, the use of flexible thread seal tape simplifies the installation process. Its pliable nature allows for easy wrapping around the threads of the fuel line, ensuring a snug fit without the need for excessive force or complex maneuvers. This not only makes the installation process more efficient but also reduces the risk of damage to the fuel line during the sealing process.

In summary, when dealing with fuel lines, opting for flexible thread seal tape is a wise choice. Its ability to accommodate movement without cracking ensures a secure and reliable seal, contributing to the overall safety and performance of the fuel system. This type of tape is a practical solution for professionals and DIY enthusiasts alike, offering a simple yet effective method to protect against fuel leaks and maintain the integrity of the vehicle's fuel delivery system.

Understanding Fuel Filter Lines: A Comprehensive Guide

You may want to see also

Installation Techniques: Learn proper installation methods for effective thread sealing on fuel lines

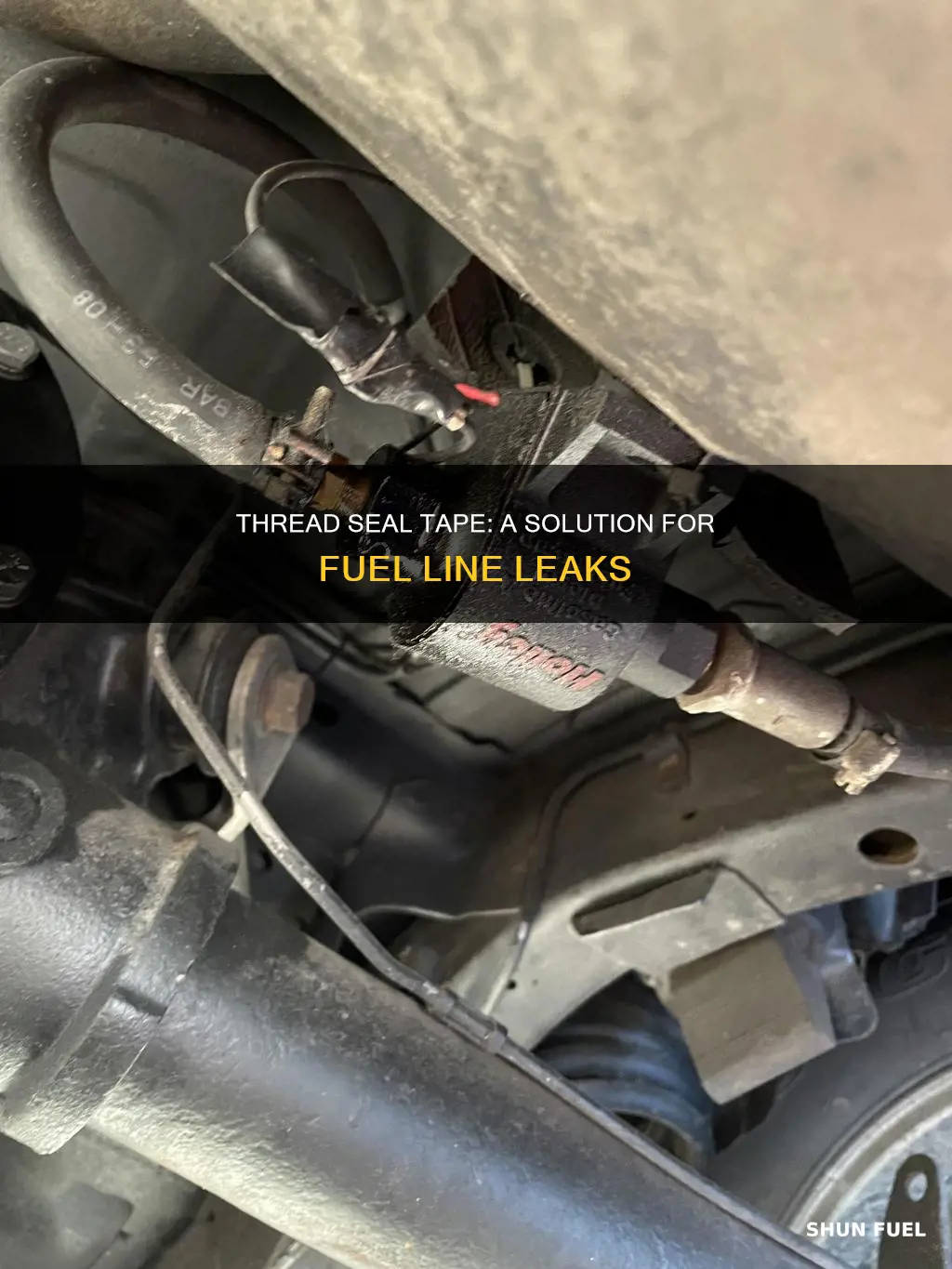

When it comes to ensuring a secure and leak-free connection for fuel lines, thread sealing is a crucial step that should not be overlooked. Proper installation techniques are essential to achieving an effective seal, especially in the context of fuel lines, where any leakage can have serious consequences. Here's a comprehensive guide to help you master the art of thread sealing for fuel lines:

Understanding the Process: Before diving into the installation, it's important to understand the purpose of thread sealing. Thread sealing is a process that creates a tight, non-porous barrier between two threaded surfaces, preventing any fuel from seeping through. This is particularly critical for fuel lines, as any leaks can lead to fuel loss, potential engine damage, and even safety hazards. The key to a successful seal lies in the careful preparation and execution of the installation process.

Gathering the Materials: To begin the installation, you'll need a few essential tools and materials. Firstly, obtain a high-quality thread seal tape or compound specifically designed for fuel lines. These products are typically made from a durable material that can withstand the corrosive nature of fuel. Additionally, ensure you have a set of thread sealing pliers or a manual thread sealer to apply the material effectively. It's also advisable to use a clean cloth or rag to wipe away any excess material and ensure a neat finish.

Preparation and Cleaning: Proper preparation is vital for a successful seal. Start by thoroughly cleaning the threads of the fuel line connectors. Remove any dirt, grease, or old sealants using a degreasing agent or a simple cleaning solution. Ensure the threads are dry and free from any contaminants before proceeding. This step is crucial as it ensures optimal adhesion of the thread seal material.

Application Technique: Now, let's delve into the installation process. Begin by wrapping the thread seal tape or compound around the threads of the fuel line connector, following a clockwise direction. Apply enough material to cover the entire thread length, ensuring it is thick enough to create a barrier. Take care not to apply too much pressure, as this can lead to an uneven seal. The goal is to create a smooth, continuous layer of the sealant. After applying the material, inspect the installation to ensure there are no gaps or overlaps, as these can compromise the seal.

Final Steps and Testing: Once the thread seal material is applied, allow it to cure according to the manufacturer's instructions. This curing process ensures the sealant sets and hardens, creating a robust barrier. After curing, it's essential to test the installation. Connect the fuel line to the engine or relevant system and check for any leaks. If no leaks are detected, your thread sealing job is a success! However, if any issues arise, carefully inspect the installation and consider reapplying the thread seal material or seeking professional assistance.

Mastering the installation techniques for thread sealing on fuel lines is a valuable skill for any mechanic or DIY enthusiast. By following these detailed steps, you can ensure a secure and reliable connection, minimizing the risk of fuel leaks and potential engine damage. Remember, proper preparation and the use of high-quality materials are key to achieving an effective and long-lasting seal.

Russell Fuel Line: Is It Fully Submersible?

You may want to see also

Frequently asked questions

Yes, thread seal tape is available in the market, and it is designed to provide a secure and leak-proof seal for fuel lines. This tape is typically made of a durable material that can withstand the corrosive nature of fuel and the pressure it may exert.

It is recommended to use a specialized thread seal tape or compound for fuel lines. Regular thread seal tape may not be as effective in preventing fuel leaks due to the unique requirements of fuel systems. Specialized products are formulated to adhere well to the fuel line material and provide a reliable seal.

Applying thread seal tape to fuel lines is a straightforward process. Start by cleaning the threads of the fuel line fitting to ensure a good bond. Wrap the tape around the threads, ensuring full coverage, and press it firmly in place. For best results, use a thread seal compound or tape that is compatible with fuel systems, and follow the manufacturer's instructions for a successful and long-lasting seal.