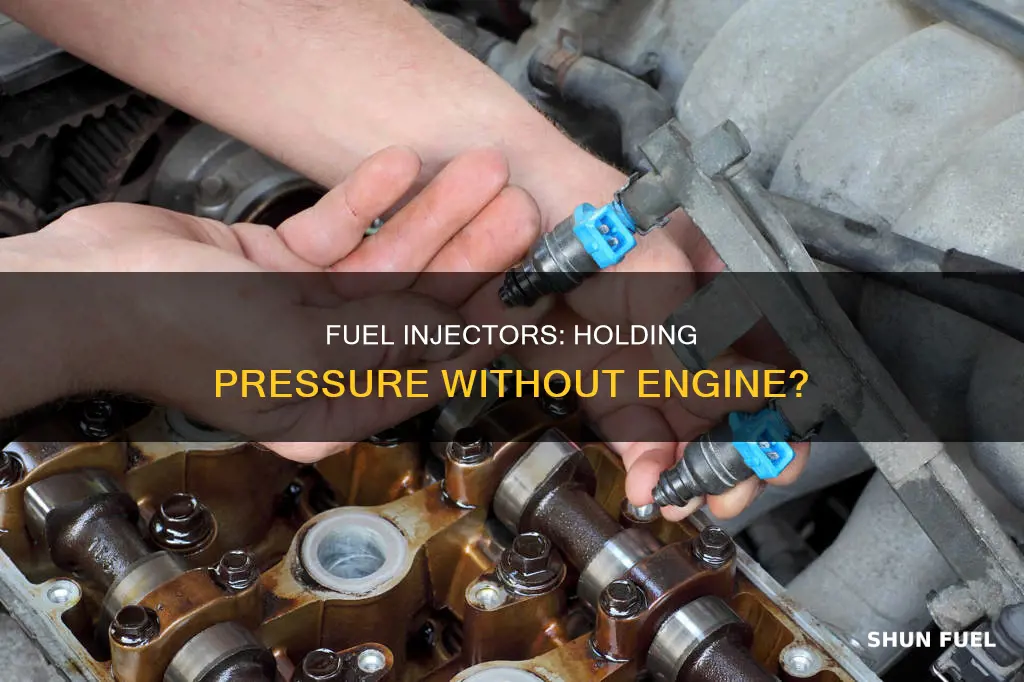

Fuel injectors are devices that control the pressure of fuel supplied to the engine. They need a pressure difference between the inlet and the outlet to spray fuel into the combustion chamber. This is called the base pressure. The base pressure is adjusted via the adjustment screw to suit the injectors and fuel pump system being used. Fuel pressure is a critical factor in the fuel injection system, and even a 1 to 3 psi change can cause noticeable driveability problems. So, the next time your engine cranks but doesn't start, it might be a good idea to check the fuel pressure.

What You'll Learn

- Fuel injectors require a pressure difference to spray fuel into the combustion chamber

- Fuel pressure is critical in the fuel injection system

- Fuel injectors can be damaged by too much pressure

- Fuel pressure can be adjusted using a regulator

- Fuel injectors need to be cleaned or replaced if they become dirty

Fuel injectors require a pressure difference to spray fuel into the combustion chamber

The base pressure is the actual applied pressure for the injector. When an engine is idling, there is a vacuum in the intake manifold. This vacuum pulls fuel out of the injectors, increasing the effective pressure across the injector to a pressure higher than the rail pressure. When a supercharged or turbocharged vehicle is in boost, the pressure inside the manifold tries to push fuel back into the injector, resisting the flow and decreasing the effective fuel pressure.

The flow rate of the injector is based on the effective pressure. Effective pressure is also known as differential pressure. It is the pressure inside the rail (rail pressure) plus the pressure differential across the injector. Rail pressure is the pressure inside the fuel rail, which can be read using a fuel pressure sensor.

A fuel pressure regulator (FPR) is a device that controls the pressure of the fuel supplied to the fuel injectors on an engine. It works by bleeding off a portion of the fuel flow from the fuel pump to the injectors. The FPR is usually mounted after the fuel rail, ensuring that the fuel rail has priority in fuel flow. The valve in the FPR controls the amount of fuel that is bled from the fuel rail by opening an outlet port, allowing fuel to flow back into the fuel tank.

The base pressure is set with the engine off but the pump running. The vacuum/boost-referenced regulator will then adjust and change the pressure in the rail based on the pressure in the manifold.

Checking Fuel Pressure: Ram Cummins Maintenance Guide

You may want to see also

Fuel pressure is critical in the fuel injection system

The fuel injectors need a pressure difference between the inlet and the outlet to spray fuel into the combustion chamber. This is called the base pressure. The base pressure is adjusted via the adjustment screw to suit the injectors and fuel pump system being used. The base pressure is set with the engine off, but the pump running.

The fuel injectors are solenoid valves that open and close when power is applied to them. The solenoid provides enough force to pull open the valve in the injector to overcome the fuel pressure keeping the injector closed. If the fuel pressure is too high, the solenoid will not have enough energy to open the valve fully, causing the engine to starve of fuel.

The fuel calibration curves in the powertrain control module (PCM) are based on OEM dyno testing using a new engine. The PCM's adaptive fuel control strategies can maintain the correct air/fuel ratio within certain limits. However, if an injector becomes clogged or fuel pressure drops below specifications, the PCM may not be able to increase injector duration enough to offset the difference, leading to a lean air/fuel mixture and potential engine misfire.

According to Jim Linder of Linder Technical Services, a provider of fuel injection training, fuel pressure is probably the most critical factor in the fuel injection system. A 1 to 3 psi change in fuel pressure can often cause noticeable driveability problems. Therefore, it is essential to maintain the correct fuel pressure to ensure the proper functioning of the fuel injection system and the engine as a whole.

Understanding High-Pressure Fuel Lines: Causes and Solutions

You may want to see also

Fuel injectors can be damaged by too much pressure

Fuel injectors are a major part of a vehicle's engine, supplying it with fuel. They can get dirty, clogged, or completely fail and need to be replaced.

To prevent damage from high fuel pressure, it is important to maintain the fuel injectors regularly. This includes cleaning them or using fuel injector cleaners at recommended intervals. It is also crucial to ensure that the fuel pressure is set correctly and adjusted if necessary when replacing or upgrading injectors.

Furthermore, it is worth noting that while high fuel pressure can cause issues, a lack of sufficient fuel pressure can also lead to problems. Insufficient fuel pressure can result in the engine not receiving enough fuel, leading to similar symptoms such as rough idling, engine misfires, and decreased fuel efficiency. Therefore, it is essential to maintain the correct fuel pressure to ensure optimal performance and prevent damage to the fuel injectors.

Adjusting Fuel Pressure Regulators in Chevy 350 TBI Engines

You may want to see also

Fuel pressure can be adjusted using a regulator

Fuel injectors are an essential component of a vehicle's fuel system, and understanding how they work is crucial for optimal performance. Fuel pressure plays a significant role in injector function, and it can be adjusted using a regulator.

There are two types of fuel systems: returnless and return style. Returnless systems do not return excess fuel to the tank, while return style systems utilise a regulator to bleed excess fuel back to the tank. Return style systems offer the advantage of maintaining a constant effective fuel pressure, which can enhance injector performance at lower fuel demands.

To adjust fuel pressure, it is important to follow the proper procedure to avoid issues such as "pressure creep," which can lead to inconsistent fuel pressure readings. This involves keeping a small amount of fuel flowing through the regulator during adjustments. One common method is to operate the engine at idle speed. However, there may be instances where adjustments need to be made with the engine turned off, in which case external means of providing a fuel flow may be necessary.

The process of adjusting fuel pressure can vary depending on the specific vehicle and fuel system configuration. In the example of a Camaro Iroc-Z, the fuel pressure can be adjusted using the adjustable fuel pressure regulator (AFPR). By screwing or unscrewing the mechanism, the fuel pressure can be increased or decreased accordingly. It is important to refer to the specific fuel injector specifications and make adjustments accordingly.

Additionally, factors such as manifold pressure come into play when considering fuel pressure. The pressure in the manifold can affect the effective fuel pressure, and this needs to be taken into account when making adjustments. In some cases, a boost-referenced return system may be utilised to maintain a constant effective fuel pressure.

Checking Fuel Pressure: Scion XD 2008

You may want to see also

Fuel injectors need to be cleaned or replaced if they become dirty

Fuel injectors are an essential component of modern vehicles, responsible for spraying gasoline into the engine in a fine mist that is easily ignited, ensuring optimal combustion and performance. Over time, fuel injectors can become clogged or contaminated, leading to a range of issues that impact the engine's performance and, if left untreated, can result in costly repairs.

After turning off the engine, residue builds up on the injector tips, containing bits of gasoline, varnish, and engine tar. This buildup can lead to a variety of problems, including rough idling, engine misfires, reduced fuel efficiency, strange noises, and increased fuel consumption. In some cases, it may even cause the check engine light to flash, indicating a serious problem.

To maintain optimal engine performance and avoid long-term damage, it is crucial to clean or replace fuel injectors when they become dirty. While cleaning is generally recommended every 15,000 to 45,000 miles, it is best to include it as part of your routine maintenance to prevent issues from arising. There are several methods for cleaning fuel injectors, ranging from using fuel additives to adding cleaning solutions or seeking professional help from a certified mechanic.

However, in severe cases of clogging or damage, replacing the fuel injectors may be necessary. Replacing all the injectors simultaneously is recommended to save time and effort. The cost of replacement can vary depending on the vehicle's make and model, typically ranging from £90 to £190 or $100 to $300 per injector.

It is important to note that fuel injectors should be properly maintained and cleaned periodically to prevent performance issues and potential engine damage. Severe clogging or damage to the injectors can lead to costly repairs and even dangerous situations if left untreated.

Testing Fuel Pump Pressure: 2003 Camry Guide

You may want to see also

Frequently asked questions

Rail pressure is the pressure inside the rail, whereas effective pressure is the pressure differential across the injector. Effective pressure is the actual applied pressure for the injector and is what injector flow rate is based on.

A fuel pressure regulator (FPR) is a device that controls the pressure of fuel supplied to the fuel injectors on an engine. It does so by bleeding off a portion of the fuel flow to the injectors from the fuel pump.

All injectors need a pressure difference between the inlet and the outlet of the injector to spray fuel into the combustion chamber. This is called the base pressure. The base pressure is adjusted on all Turbosmart FPRs via the adjustment screw to suit the injectors and fuel pump system being used.

One of the first questions that should always be asked when diagnosing a fuel-related complaint on a fuel-injected engine is, "What is the fuel pressure?". The fuel pressure should be measured with a gauge and checked with the key on, engine off, then again with the engine running. If pressure is not within specifications, further diagnosis is required.