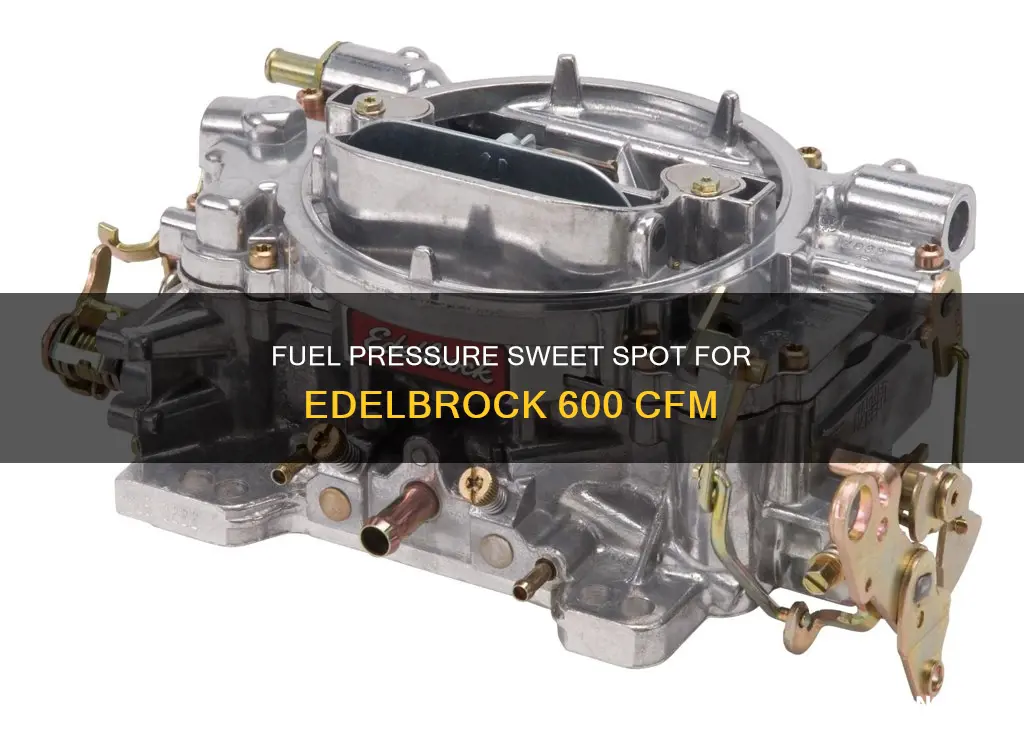

Edelbrock 600 CFM is a carburetor that is used in cars. Carburetors are devices that mix air and fuel in the internal combustion engines of cars. Edelbrock 600 CFM has been known to face some issues with flooding. This can be caused by excessive fuel pressure, which can be remedied by using a fuel pressure regulator. Edelbrock recommends a fuel pressure of 4.5-5.5 psi, with a maximum of 6.5 psi, to avoid issues with the needle and flooding.

| Characteristics | Values |

|---|---|

| Optimal fuel pressure | 4.5-5.5 psi |

| Maximum fuel pressure | 6.5 psi |

| Fuel pressure regulator range | 4-12 psi |

What You'll Learn

Edelbrock 1406 CFM fuel pressure-electric pump

The Edelbrock 1406 600 CFM carburettor is designed to work with fuel pressure between 4.5 and 5.5 psi, with an absolute maximum of 6.5 psi. Fuel pressure above this range will cause the carburettor to flood with fuel, which will leak out of the boosters.

Fuel pressure can be controlled with a regulator, and some users have reported success with this method. However, some have also reported that even with a regulator, fuel pressure can still exceed the recommended maximum.

The Edelbrock carburettor is sensitive to high fuel pressure, and even a small increase in pressure can cause operational issues. Therefore, it is important to ensure that the fuel pump is not delivering excessive pressure.

If you are experiencing issues with fuel pressure, it is recommended to check the fuel pump and consider installing a regulator to maintain the optimal pressure range for the Edelbrock 1406.

Fixing Low Fuel Pressure: Cost and Solutions

You may want to see also

Fuel pressure regulator

To maintain the desired fuel pressure, a fuel pressure regulator is often necessary. This device helps control and maintain the correct fuel pressure supplied to the carburettor, ensuring it stays within the optimal range. By installing a fuel pressure regulator, you can fine-tune the fuel pressure to match the specifications provided by the carburettor manufacturer. This is particularly important when using aftermarket fuel pumps or experiencing fuel pressure-related issues, such as flooding or lean conditions.

When selecting a fuel pressure regulator, it is essential to choose one that is compatible with your fuel system and capable of handling the desired pressure range. Additionally, a fuel pressure gauge can be invaluable in monitoring the fuel pressure and making adjustments as needed. It is also worth noting that fuel pressure requirements can vary depending on factors such as engine modifications, camshaft specifications, and vehicle usage. Therefore, it is always advisable to consult with experts or refer to reliable sources for specific recommendations regarding your particular setup.

In some cases, you may need to make adjustments to the regulator to achieve the desired fuel pressure. Most fuel pressure regulators come with an adjustment screw that allows you to increase or decrease the pressure. However, it is crucial to exercise caution when making these adjustments, as turning the screw too far can lead to excessive fuel pressure, resulting in carburettor flooding and potential safety hazards. Always refer to the manufacturer's instructions and use a fuel pressure gauge during the adjustment process.

By using a fuel pressure regulator and maintaining the optimal fuel pressure, you can improve the performance, reliability, and safety of your vehicle, ensuring a more enjoyable driving experience.

Fuel Pressure Regulator: Shrader Valve Low Pressure Culprit?

You may want to see also

Fuel pump pressure and flooding

Fuel pump pressure can cause flooding in Edelbrock 600 CFM carburettors. The optimal fuel pressure for these carburettors is between 4.5 and 5.5 psi, with a maximum of 6.5 psi. Going over this limit will cause flooding issues, as the fuel pressure will be too high for the needle and seat to handle, resulting in fuel leaking past the needle and seat and into the engine.

To prevent flooding due to fuel pump pressure, it is recommended to use a fuel pressure regulator to maintain the optimal fuel pressure range. Additionally, ensuring that the choke is opening fully when the engine is warmed up is crucial, as a closed choke can lead to a rich air-fuel mixture and flooding.

Some stock fuel pumps may produce fuel pressure higher than the optimal range for Edelbrock carburettors, so it is important to check and regulate the fuel pressure if necessary. It is also worth noting that some aftermarket performance fuel pumps may cause similar issues.

Furthermore, other factors such as a faulty fuel pump diaphragm, dirty carburettor needles, or a blown head gasket can also lead to flooding issues. Therefore, it is essential to regularly maintain and inspect these components to prevent flooding and ensure the optimal performance of the engine.

Fuel Stabilizer: Prolonging Your Pressure Washer's Lifespan

You may want to see also

Fuel pressure gauge

A fuel pressure gauge is a valuable tool for monitoring the fuel pressure in your vehicle's engine. It helps to ensure that the fuel pump and regulator are functioning correctly and that the right amount of pressure is being delivered on a wide-open throttle. By keeping an eye on your fuel system, you can make sure it is performing at its best.

The installation process for a fuel pressure gauge varies depending on the application, but it typically involves connecting the gauge to the fuel filter housing, fuel pump, or fuel rail. In some cases, additional threading adapters may be required. The gauge should come with detailed instructions and all the necessary hardware for a successful installation.

Having a fuel pressure gauge can be extremely useful for diagnosing fuel-related issues in your vehicle. For instance, if you suspect that your fuel pressure sensor is faulty, the gauge can help confirm whether the problem is indeed with the sensor or if there is an issue with the fuel pressure itself. This can save you time and money by providing accurate information to guide your repairs.

In addition to diagnostic purposes, a fuel pressure gauge can also help prevent damage to your fuel system. Low fuel pressure can cause rough idling, poor performance, and reduced fuel economy, while high fuel pressure can lead to a rich air-fuel mixture, resulting in black exhaust and high emissions. By monitoring your fuel pressure with a gauge, you can identify and address these issues promptly, potentially avoiding costly repairs and engine failure.

Harley Fuel Pressure: Optimal Performance and Maintenance

You may want to see also

Fuel line

Edelbrock recommends a fuel pressure of 4.5-6 psi for its carburetors. Fuel pressure regulators are available to maintain this pressure.

The Edelbrock 1406 600 CFM carburetor is prone to flooding issues, which can be caused by fuel pump pressure that is too high. Edelbrock techs insist that 4.5-5.5 psi is optimal, with no more than 6.5 psi. Anything more than 6.5 psi will cause needle and seat issues and flooding.

To prevent flooding, a fuel pressure regulator can be installed to maintain the optimal pressure. The regulator should be installed in the fuel line between the fuel pump and the carburetor. The regulator will restrict the fuel pressure to the desired level, preventing it from exceeding the maximum pressure rating of the carburetor.

When selecting a fuel pressure regulator, it is important to consider the flow rate of the fuel pump and the engine's fuel requirements. The regulator should be able to handle the flow rate of the pump and provide enough fuel for the engine under all operating conditions.

Additionally, the type of fuel line used can also affect fuel pressure. Using a fuel line with a larger diameter can help reduce pressure loss and ensure that the engine receives an adequate fuel supply. It is also important to ensure that the fuel line is not restricted or clogged, as this can affect fuel flow and pressure.

In summary, to maintain the optimal fuel pressure for an Edelbrock 600 CFM carburetor, a fuel pressure regulator should be installed in the fuel line. The regulator should be selected based on the fuel pump's flow rate and the engine's fuel requirements. Additionally, using a fuel line with an appropriate diameter and ensuring it is unrestricted will help maintain the desired fuel pressure.

Replacing Chevy Equinox's High-Pressure Fuel Pump: Step-by-Step Guide

You may want to see also

Frequently asked questions

The optimal fuel pressure for an Edelbrock 600CFM is between 4.5 and 5.5 PSI. Going above 6.5 PSI can cause issues with flooding and the needle/seat.

Yes, a stock fuel pump can be used with an Edelbrock 600CFM. However, some stock pumps may produce fuel pressure between 6-9 PSI, which is above the optimal range for the Edelbrock 600CFM. It is recommended to use a fuel pressure regulator to maintain the optimal fuel pressure.

Signs of too much fuel pressure with an Edelbrock 600CFM can include flooding, fuel leaking from the boosters, and fuel-fouled spark plugs. It is important to monitor fuel pressure and make adjustments as needed to avoid these issues.