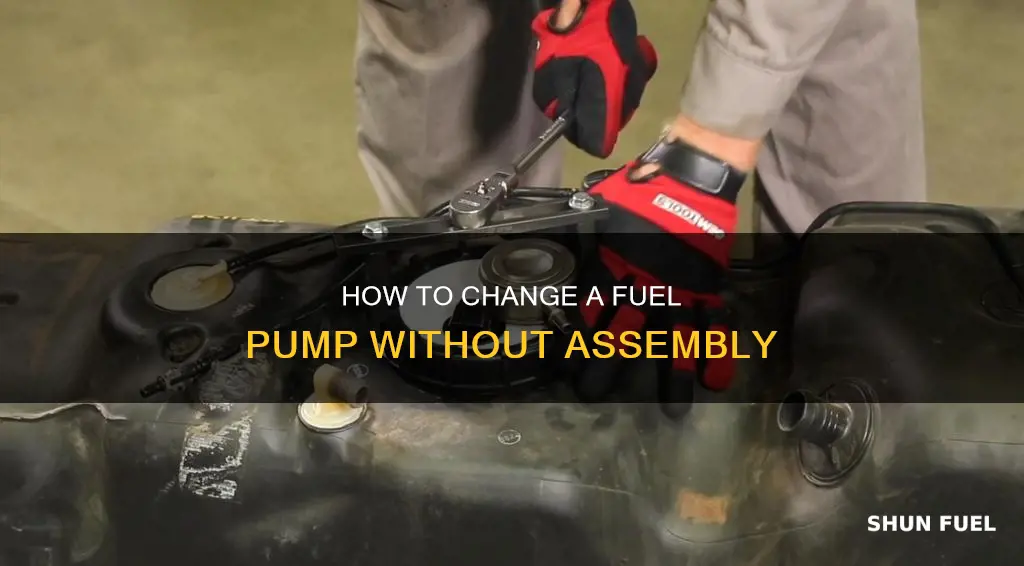

Replacing a fuel pump can be a time-consuming and expensive process, but it doesn't have to be. Depending on the make and model of your car, you may be able to replace the fuel pump without removing the entire assembly. Some vehicles have fuel pump access panels under the rear passenger seat, which can make the job much easier. However, if your vehicle doesn't have an access panel, you will need to remove the fuel tank to access the pump. This can be a tricky process, as you will need to drain the fuel tank and work with flammable liquids. It's important to take the necessary safety precautions and have the correct tools before attempting to replace a fuel pump.

What You'll Learn

Safety precautions when replacing a fuel pump

Replacing a fuel pump can be a challenging task, but taking the proper safety precautions can make the process safer and more manageable. Here are some essential safety precautions to follow when replacing a fuel pump:

Work in a Safe Environment

Before starting, ensure you are working in a well-ventilated area, preferably outdoors, to minimise the risk of inhaling toxic fumes and to reduce the chance of fire. Keep the workspace free from any sources of ignition, such as pilot lights, incandescent light bulbs, or open flames. Have a fire extinguisher readily available in case of an emergency. It is also crucial to refrain from smoking while working on the fuel system.

Use Proper Safety Gear

Always wear safety glasses and gloves to protect your eyes and hands from fuel spills and splashes. Consider wearing appropriate clothing that covers your body to avoid direct contact with fuel.

Relieve Fuel System Pressure

It is important to relieve the fuel system pressure before opening the fuel lines. This can be done by running the engine and pulling the fuel pump relay, causing the engine to stall. Alternatively, with the engine off, you can momentarily press the Schrader valve on the pressure line, capturing the small fuel spray that releases.

Disconnect the Battery

Before beginning any work, be sure to disconnect the negative battery cable. This step is crucial for safety, as it helps prevent any accidental electrical discharges that could cause sparks or short circuits.

Handle Fuel with Care

Fuel is highly flammable and dangerous. When removing fuel from the tank, use a hand siphon pump instead of an electric pump to avoid the risk of sparks and explosions. Store any fuel removed from the tank in an approved container, such as a gas caddy or gas can. Ensure you have clean-up materials ready to immediately wipe up any spills or leaks.

Follow Vehicle-Specific Instructions

Refer to your vehicle's service manual or online tutorials for specific instructions on replacing the fuel pump for your particular make and model. The process can vary significantly between different vehicles, so having the correct information is essential for a safe and successful replacement.

How to Replace a Fuel Sensor Without Tools?

You may want to see also

How to access a fuel pump

To access a fuel pump, you will need to locate it first. In most vehicles, the fuel pump is located in the fuel tank.

Before you begin, ensure you have the necessary tools and safety equipment. This includes safety glasses, gloves, appropriate clothing, a jack and jack stands or a lift, a wrench and/or socket set, a vehicle-specific repair manual, rags or other absorbent materials, and a fire extinguisher. It is also important to work in a well-ventilated area away from any sources of sparks or flames.

Now, follow these steps:

- Park your vehicle on a firm, level surface and engage the parking brake.

- If your vehicle has an access panel, you may be able to access the pump without removing the tank. Check your vehicle's manual to determine if this is possible.

- If there is no access panel, you will need to remove the fuel tank. To do this, lift the vehicle and place it on jack stands or use a lift to access the underside of the car.

- Relieve the fuel system pressure. This step can vary depending on the vehicle, so refer to your service manual for specific instructions.

- Disconnect the filler neck from the fuel tank. Refer to your service manual for detailed instructions.

- Support the fuel tank with the jack and a block of wood.

- Remove the bolts or straps holding the fuel tank in the vehicle.

- Disconnect the wiring connections, fuel lines, and vent hoses on the top of the tank.

- Carefully lower the fuel tank out of the vehicle.

- Clean the area around the existing fuel pump assembly to prevent dirt or debris from falling into the tank during removal.

- Refer to your service manual for instructions on removing the fuel pump assembly. Typically, there is a plate held in place with screws or bolts that, once removed, allows access to the pump.

At this point, you should have access to the fuel pump and can proceed with the necessary repairs or replacements. Remember to exercise caution and follow safety procedures throughout the process.

Fuel Injectors: MPG Gain or Drain?

You may want to see also

Removing the fuel pump

Before you begin, ensure you have all the necessary parts and tools for the job. It is also important to check your tank for any leaks or damage, as you will have the tank out and can easily replace it. Check if your tank has a drain cock or drain plug on the bottom side, as this will make it easier to drain the fuel.

As with any project involving fuel, safety is paramount. Make sure you are wearing safety glasses and gloves, and work in a well-ventilated area away from any sources of ignition, such as pilot lights or incandescent light bulbs. Have a fire extinguisher on hand and do not smoke. Remember that static electricity from your clothes or the vehicle's interior can create a spark, so take care when removing fuel from the tank. Do not use an electric pump, and instead opt for a hand siphon pump.

First, disconnect the negative battery cable. Jack up your vehicle and place it on jack stands or use a lift to access the underside of the car. Next, relieve the fuel system pressure. The method for doing this will vary depending on the vehicle, so refer to the service manual for your specific model.

Disconnect the filler neck from the fuel tank, following the instructions in the service manual. Support the fuel tank with a jack and a block of wood. Remove the bolts from the straps holding the fuel tank in place, and carefully disconnect the wiring connections, fuel lines, and vent hoses on the top of the tank. Once the connections are released, carefully lower the tank out of the car.

Clean the top of the tank around the existing fuel pump assembly to prevent any dirt or debris from falling into the tank during removal. Refer to your service manual for instructions on removing the fuel pump assembly. Typically, there is a plate held in place with screws or bolts that, once released, allows for the removal of the pump.

Now, you can remove the fuel pump assembly. Keep in mind that some fuel pumps require parts to be transferred from the old unit. You may need to use a hammer and a block of wood to loosen the retaining ring holding the pump in the tank. Place the edge of the wood on a tab on the ring and hit it with the hammer, turning it left to loosen it. Be careful not to use something with a sharp metal edge, as this can damage the ring.

With the retaining ring loosened, carefully remove the assembly from the tank, being mindful not to break the sending unit float. Drain the fuel into an approved container. Remove the bottom filter, and disconnect the sending unit by carefully releasing the small tab holding the connector.

The next step is to free the plastic top piece by carefully pushing in the tabs that are holding it in place. Once the tabs are released, use a screwdriver to carefully pry the tab for the fuel pump connector and gently pull it out. Be very cautious during this step, as the wires for the fuel pump may be rigid from being soaked in gas, and you risk breaking them if you apply too much force.

Set the plastic top piece aside and remove the spring between the fuel pump feed tube and the plastic top. Try to pull out this tube as well, noting its orientation.

At this point, you should be able to see the fuel pump clearly. However, it may still be secured to a secondary filter in the bottom of the housing. To release it, try flipping the housing upside down and gently hitting it on a block of wood on the ground. This should "shock" the fuel pump out of the housing. Make sure to keep track of any rubber or metal washers that fall out, as these will need to go back in.

Now that the fuel pump is removed, you can install the new pump by following the reverse procedure.

Replacing Fuel Pump Relay: DIY Guide to Fixing Your Car

You may want to see also

Installing a new fuel pump

Preparation:

Before beginning the installation, it is important to ensure that you have the correct parts and tools required for the job. Refer to your vehicle's owner's manual to understand the specific requirements for your car. Some vehicles have fuel pump access panels, while others require removing the fuel tank. Additionally, ensure you are wearing protective gear, such as gloves and safety glasses, and have clean-up materials ready in case of any spills.

Vehicle Preparation:

Park your vehicle on a firm, level surface and engage the parking brake. Disconnect the negative battery cable. If your fuel tank contains gas, drain it into an approved container. You may need to refer to your service manual to relieve the fuel system pressure.

Fuel Tank Removal:

Remove the clamps from the fill lines and then remove the fill lines. Use a rag to avoid getting dirt in the tank. Support the tank and carefully remove the straps and lower it.

Fuel Pump Assembly Removal:

Remove the pump assembly and keep in mind that some fuel pumps require transferring parts from the old unit. Clean the top of the tank around the existing fuel pump assembly to prevent any debris from falling into the tank. Refer to your service manual for detailed instructions on removing the fuel pump assembly.

New Fuel Pump Installation:

Install the new fuel pump by following the reverse order of the removal process. Ensure that the pump is securely connected and that all components, such as the fuel lines, wiring connections, and vent tubes, are properly reinstalled.

Reinstalling the Fuel Tank:

Carefully raise the tank back into position and reconnect the wire connectors and fuel lines. Reconnect the straps and fill lines, ensuring the tank is properly positioned.

Final Checks:

Partially fill the tank and run the vehicle to inspect for any leaks. Remember to replace the fuel filter to ensure your new pump runs smoothly.

By following these steps and paying attention to safety precautions, you can successfully install a new fuel pump and get back on the road.

How to Safely Increase Your Fuel Hose's Inner Diameter

You may want to see also

Testing the new fuel pump

Electrical Test:

First, perform an electrical test to check if the power is reaching the pump. Refer to your vehicle's service manual to locate the fuel pump fuse in the fuse box. Check if the fuse is blown, which will appear broken or burned. If the fuse is intact, move on to checking the voltage at the pump itself. Ensure you are getting the correct voltage reading at the pump, as specified in the service manual. Perform a drop test using a voltmeter to ensure the power wire shows the full voltage, and the grounding wire is properly grounded.

Fuel Pressure Test:

Next, conduct a fuel pressure test to ensure adequate fuel pressure and volume. Start by eliminating the fuel filter as a potential cause of issues. Remove the filter and drain excess fuel from it. Use a rubber hose on the filter inlet and blow through it, checking for resistance. Inspect the screen for any debris, and replace the filter if necessary.

Now, acquire a fuel pressure gauge, which can be purchased or borrowed from auto shops. Locate the fuel pump test point near the fuel injectors and attach the gauge to the test fitting or port. Warm up the engine slightly, then check the fuel pressure at idle speed and the rated speed specified in your pump specifications. If the pressure matches the specifications and increases as you rev the engine, your fuel pump is functioning correctly.

Additional Checks:

- Fuel Pump Noise: With the key in the ignition turned to the "ON" or "accessory" position, listen for a clicking or buzzing sound, indicating the fuel pump is operational.

- Fuel Pressure Valve: If you don't have access to a fuel pressure gauge, you can take your vehicle to a technician or use a fuel pressure valve near the engine to manually check the fuel pressure. Compare this reading with the recommended fuel pressure values.

- Fuel Volume: Perform a fuel pump volume test to ensure the pump produces adequate volume. Consult your repair manual for specific instructions and specifications for your vehicle.

Remember to adhere to safety precautions when working on your vehicle's fuel system. Keep a fire extinguisher nearby and ensure proper ventilation to avoid any potential hazards.

Fuel Pump Replacement: Can It Boost Your Gas Mileage?

You may want to see also

Frequently asked questions

Yes, some vehicles have fuel pump access panels under the rear passenger seat, so check your owner's manual before starting any work.

As you will be dealing with gasoline, a highly flammable substance, do not smoke while working and keep all sources of sparks or flame away from the vehicle and fuel tank. Keep in mind that light bulbs can be very hot, so use LEDs if you need to work at night. Also, have a fire extinguisher on hand.

You will need a jack and jack stands or a lift to raise your vehicle, a wrench and/or socket set, rags or other absorbent material, safety glasses, and gloves.