Testing the fuel quality of a tesla car can be a crucial step in maintaining its performance and longevity. By conducting fuel tests, you can identify any potential issues with the car's fuel system, such as contamination or degradation, which could lead to decreased efficiency, engine problems, or even safety hazards. This process involves analyzing the fuel's properties, including its chemical composition, moisture content, and acidity levels, to ensure it meets the manufacturer's specifications and standards. Regular fuel testing can help prevent unexpected breakdowns and costly repairs, allowing you to keep your tesla car running smoothly and reliably.

What You'll Learn

- Visual Inspection: Check for leaks, corrosion, and damage to the fuel tank and lines

- Fuel Quality: Measure fuel density and acidity to assess its condition

- Engine Diagnostics: Use diagnostic tools to identify fuel-related issues

- Performance Testing: Monitor engine performance and fuel efficiency under load

- Emission Analysis: Measure exhaust emissions to detect fuel degradation

Visual Inspection: Check for leaks, corrosion, and damage to the fuel tank and lines

When conducting a visual inspection of a Tesla car's fuel system, it's crucial to pay close attention to the fuel tank and associated lines for any signs of leaks, corrosion, or damage. This inspection is an essential part of maintaining the vehicle's overall health and ensuring its safe operation. Here's a detailed guide on what to look for:

Fuel Tank Inspection: Start by examining the fuel tank, which is typically located in the rear of the vehicle. Check for any visible cracks, rust, or corrosion on the tank's surface. Over time, fuel tanks can develop small cracks due to the corrosive effects of gasoline or diesel, especially if the vehicle has been exposed to harsh weather conditions. Look for any signs of leakage around the tank, such as stains on the ground or a sweet, gasoline-like odor. These could indicate a potential issue that requires immediate attention.

Fuel Lines and Hoses: The fuel system of a Tesla consists of several lines and hoses that carry fuel from the tank to the engine. Inspect these components for any signs of damage, cracks, or leaks. Start at the fuel tank and trace the lines to the engine compartment. Check for any bulging, softening, or cracks in the hoses and lines. Leaks can occur at connections, fittings, or where the lines attach to the tank or engine. Even a small leak can lead to significant issues over time, so any signs of moisture or fuel residue should be addressed promptly.

Corrosion and Rust: Corrosion is a common issue in fuel systems, especially in older vehicles. Look for signs of rust or corrosion on the fuel tank, lines, and any metal components in the engine compartment. This can often be identified by a white or brown powdery substance or small holes in the metal. Corrosion can lead to fuel contamination and reduced engine performance. If you notice significant corrosion, it may be necessary to clean or replace affected parts.

Damage and Contamination: During the visual inspection, also look for any visible damage to the fuel tank or lines, such as punctures or tears. This could be caused by accidents, road debris, or improper maintenance. Additionally, check for any signs of fuel contamination, such as water accumulation in the tank or lines. Water in the fuel can lead to engine misfires and other performance issues. If you suspect contamination, it's best to have the fuel system professionally drained and cleaned.

By thoroughly examining the fuel tank and lines during a visual inspection, you can identify potential issues early on, ensuring that your Tesla's fuel system remains in optimal condition. Regular maintenance and prompt attention to any visual defects will contribute to the overall longevity and reliability of your vehicle.

Ethanol Fuel: Safe for Your Car's Engine?

You may want to see also

Fuel Quality: Measure fuel density and acidity to assess its condition

The quality of fuel is a critical aspect of vehicle maintenance, especially for those with high-performance engines or those operating in extreme conditions. Assessing fuel condition is essential to ensure optimal engine performance and longevity. One effective method to evaluate fuel quality is by measuring its density and acidity.

Fuel density is a measure of the mass of fuel per unit volume. It provides an indication of the fuel's concentration and can be used to identify potential issues. Low-density fuel may suggest contamination or degradation, which can lead to reduced engine power and efficiency. For instance, if the fuel density is significantly lower than the expected value for the given fuel type, it could indicate the presence of water or impurities, which can cause engine misfires and reduced performance. On the other hand, high-density fuel might be a sign of over-concentration, potentially leading to engine knocking and performance issues.

Measuring fuel density can be done using specialized equipment, such as a fuel density meter or hydrometer. These devices are designed to accurately determine the specific gravity of the fuel, which is directly related to its density. By comparing the measured density to the expected value for the fuel type, you can quickly identify any deviations that may indicate fuel degradation or contamination.

Acidity, or the pH level, of fuel is another crucial factor in assessing its quality. Fuel acidity can be influenced by various factors, including the type of fuel, storage conditions, and the presence of impurities. High acidity in fuel can lead to corrosion of the fuel system components, including the fuel pump, injectors, and engine internal parts. This corrosion can result in reduced engine performance, increased maintenance requirements, and even engine failure over time.

To measure fuel acidity, you can use a pH meter or a fuel acid test kit. These tools allow you to determine the pH level of the fuel, which provides valuable information about its condition. If the fuel's pH is outside the acceptable range, it may indicate the need for fuel treatment or the presence of contaminants that can cause engine problems. Regularly monitoring fuel acidity is essential, especially for vehicles operating in regions with varying fuel quality or those exposed to harsh environmental conditions.

In summary, measuring fuel density and acidity is a practical approach to assessing fuel quality. These measurements provide valuable insights into the fuel's condition, helping to identify potential issues such as contamination, degradation, or corrosion risks. By regularly checking these parameters, vehicle owners and operators can ensure that their engines perform optimally and maintain the longevity of their vehicles, especially in challenging operating environments.

Smoke Signals: Fuel Filter's Role in Car Emissions

You may want to see also

Engine Diagnostics: Use diagnostic tools to identify fuel-related issues

When it comes to engine diagnostics, identifying fuel-related issues is crucial for maintaining optimal vehicle performance. Modern vehicles are equipped with sophisticated diagnostic tools that can help pinpoint problems associated with fuel systems. These tools are designed to provide valuable insights into the engine's behavior and can be a mechanic's best friend when it comes to troubleshooting fuel-related concerns.

One essential diagnostic tool for fuel-related issues is the Engine Control Unit (ECU). The ECU is the brain of the vehicle, managing various engine functions, including fuel injection. It continuously monitors engine parameters and can detect anomalies in fuel pressure, temperature, and flow. If the ECU identifies a problem, it triggers a diagnostic trouble code (DTC) that can be read using a scan tool. For example, a code P0250 might indicate a fuel pressure regulator issue, allowing mechanics to quickly narrow down the problem area.

Another valuable tool is the fuel pressure gauge, which provides a direct measurement of the fuel pressure in the system. By connecting this gauge to the fuel rail, mechanics can assess whether the fuel pressure is within the specified range. Low fuel pressure can lead to poor engine performance, while excessive pressure may cause engine knocking. This simple yet effective tool enables technicians to quickly identify and address fuel pressure-related problems.

Additionally, diagnostic scanners, often referred to as OBD-II (On-Board Diagnostics II) scanners, are widely used for engine diagnostics. These scanners can read and interpret the DTCs stored in the vehicle's computer, providing a comprehensive overview of potential fuel-related issues. They can detect problems with fuel injectors, fuel pumps, and even the fuel tank itself. For instance, a code related to a faulty fuel pump may prompt a mechanic to check the pump's operation and ensure it delivers fuel efficiently to the engine.

Furthermore, the use of a fuel flow meter can be beneficial in diagnosing fuel delivery issues. This tool measures the volume of fuel flowing through the system, allowing technicians to identify blockages, leaks, or inefficient fuel management. By comparing the measured flow rate with the expected value, mechanics can pinpoint problems in the fuel lines, injectors, or even the ECU's control of the fuel system.

In summary, engine diagnostics play a vital role in identifying fuel-related issues, and the use of specialized tools is essential for effective troubleshooting. From ECU-based diagnostics to fuel pressure gauges and OBD-II scanners, these tools empower mechanics to quickly and accurately diagnose problems, ensuring the vehicle's fuel system operates optimally. Regular use of these diagnostic techniques can help prevent costly repairs and maintain the longevity of the vehicle's engine.

Unleashing Speed: Efficiency in the World of Racing

You may want to see also

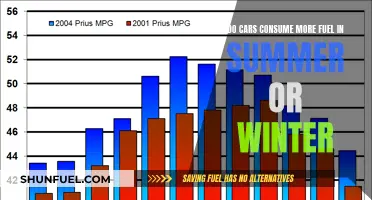

Performance Testing: Monitor engine performance and fuel efficiency under load

Performance testing is a critical aspect of evaluating a vehicle's capabilities, especially when it comes to monitoring engine performance and fuel efficiency under varying conditions. This type of testing provides valuable insights into how a vehicle behaves when subjected to different loads, helping engineers and enthusiasts understand its true potential. Here's a detailed guide on how to conduct this type of test:

- Load Simulation: Begin by simulating various driving conditions that place different loads on the engine. This can be achieved using a dynamometer, which is a specialized piece of equipment that measures and controls the power and torque output of an engine. By adjusting the dynamometer's settings, you can replicate different driving scenarios, such as acceleration, cruising, and highway driving. The goal is to create a controlled environment that mimics real-world driving conditions while allowing for precise measurements.

- Engine Performance Monitoring: During the test, closely monitor the engine's performance parameters. These parameters include:

- Engine Speed: Measure and record the engine's RPM (revolutions per minute) as it accelerates and maintains different speeds. Higher RPMs often indicate increased power output.

- Power and Torque: Use the dynamometer to measure the engine's power and torque output at various RPMs. These measurements will provide insights into the engine's performance characteristics, including its ability to generate force and accelerate.

- Fuel Consumption: Accurately track the fuel consumption rate during the test. This can be done by monitoring the fuel level in the tank or using a fuel flow meter. Measuring fuel efficiency under load is crucial to understanding how the vehicle performs in everyday driving situations.

- Data Collection and Analysis: As the test progresses, collect data at regular intervals to ensure a comprehensive evaluation. This data should include engine speed, power, torque, and fuel consumption. Advanced testing equipment and software can automate this process, ensuring accurate and consistent measurements. After the test, analyze the collected data to identify trends and patterns. Look for any anomalies or deviations from expected behavior, as these could indicate potential issues with the vehicle's fuel system or engine performance.

- Load Testing Scenarios: Design specific test scenarios to cover a wide range of driving conditions. For example, you might start with a low-load scenario, such as cruising at a steady speed on a flat road, and gradually increase the load by applying higher RPMs or simulating acceleration. By doing so, you can observe how the engine and fuel system respond to different challenges. This iterative process allows for a comprehensive evaluation of the vehicle's performance and efficiency.

- Comparison and Benchmarking: Compare the test results with industry standards or previous model year data to benchmark the vehicle's performance. This comparison can help identify areas of improvement or potential issues. For instance, if the fuel consumption under load is significantly higher than expected, it may indicate a problem with the fuel injection system or engine efficiency. By analyzing these differences, engineers can make informed decisions to optimize the vehicle's performance.

Conducting performance testing with a focus on engine and fuel efficiency under load is an essential practice in the automotive industry. It allows for the identification of potential issues, ensures vehicle reliability, and provides valuable data for both manufacturers and consumers. This testing process contributes to the overall improvement of vehicle performance and efficiency, making it an indispensable tool in the development and evaluation of modern transportation.

The Ultimate Guide to the Most Fuel-Efficient Cars

You may want to see also

Emission Analysis: Measure exhaust emissions to detect fuel degradation

Emission analysis is a critical method to assess the quality of fuel and its impact on vehicle performance and environmental emissions. When it comes to testing car fuel, measuring exhaust emissions is an effective way to detect any degradation or contamination in the fuel. This analysis provides valuable insights into the fuel's composition and its potential effects on engine operation and the environment.

The process involves collecting and examining the exhaust gases emitted from the vehicle's tailpipe. By utilizing specialized equipment, such as an exhaust gas analyzer, technicians can measure various parameters, including the concentration of pollutants like carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM). These emissions are directly related to the fuel's combustion quality and can indicate any issues with the fuel's performance.

One key aspect of emission analysis is the detection of fuel degradation, which can occur due to various factors. For instance, fuel can degrade over time due to oxidation, contamination with water or other impurities, or improper storage conditions. When fuel degrades, it may contain higher levels of volatile compounds, leading to poor combustion and increased emissions. By measuring exhaust emissions, technicians can identify these issues and determine the extent of fuel degradation.

To perform this analysis, a sample of exhaust gas is drawn from the vehicle's exhaust system and analyzed using advanced sensors and instruments. These tools can provide real-time data on emission levels, allowing for immediate detection of any anomalies. Technicians can compare the measured emissions with standard values to assess the fuel's quality and performance. Advanced emission analysis systems can even identify specific fuel components and their concentrations, providing a comprehensive understanding of the fuel's condition.

In summary, emission analysis plays a vital role in evaluating fuel quality and its impact on vehicle emissions. By measuring exhaust emissions, technicians can detect fuel degradation, identify potential issues, and ensure that the fuel meets the required standards. This process is essential for maintaining vehicle performance, optimizing fuel efficiency, and minimizing environmental impact, especially in the context of electric and alternative fuel vehicles. Regular emission testing and analysis contribute to a more sustainable and environmentally friendly approach to transportation.

Troubleshooting: Car Fuel Gauge Issues and Solutions

You may want to see also

Frequently asked questions

Tesla vehicles do not use traditional fuel, so you won't need to check the fuel quality in the same way as a conventional car. However, you can monitor the battery health and performance to ensure optimal operation. Tesla provides detailed diagnostics and analytics through its mobile app and in-car display, allowing you to track battery range, charging efficiency, and overall battery health.

A degraded battery in a Tesla car can lead to reduced range and performance. Some common indicators include a noticeable decrease in the car's range, slower charging times, and a decline in overall acceleration. Tesla owners can also look for error messages or warnings on the dashboard, such as 'Battery Range Warning' or 'Battery Degradation Alert'. Regular software updates from Tesla can also provide insights into battery health.

Tesla's battery system is designed for specific voltage and chemical composition, and using a fuel tester designed for conventional fuel may not provide accurate results. It's recommended to rely on Tesla's built-in diagnostic tools and professional maintenance services to assess battery health. Tesla technicians have access to specialized equipment and knowledge to evaluate battery performance accurately.

Tesla suggests performing a battery health check at least once a year or whenever you notice a significant change in performance. Regular maintenance and software updates can help optimize battery usage and longevity. Tesla also offers battery replacement programs for eligible vehicles, ensuring you can maintain optimal performance over time.

While Tesla provides comprehensive monitoring features, attempting DIY tests at home may not be accurate or safe. The battery system is complex and requires specialized knowledge and equipment. It's best to rely on Tesla's official channels for battery health assessments, ensuring you receive reliable and up-to-date information.