A fuel pump is a critical component of a car's powertrain system, transferring petrol or diesel from the fuel tank to the engine. A malfunctioning fuel pump can cause a range of issues, from a lack of power output to a complete breakdown of the vehicle. Therefore, it is important to regularly check the fuel pump's performance and pressure to ensure that it is functioning optimally. Checking the fuel pressure can help identify potential issues and ensure proper fuel delivery to the engine, maintaining the vehicle's efficiency and performance. This can be done by following specific steps, such as using a fuel pressure tester or gauge, and comparing the readings to the manufacturer's specifications.

| Characteristics | Values |

|---|---|

| When to check fuel pressure | If the vehicle is moving at a consistent speed and then suddenly surges forward, or if the temperature of the car rises and the car stalls. |

| What to check | Check the fuel pressure gauge to see how much fuel is getting to the engine. |

| What to do | Check the owner's manual to see how much pressure should be exerted when the pump is operating properly. If the pressure is lower than the recommended amount, your fuel pump needs attention. |

| Engine won't start | If the engine won't start, check for low pressure in the fuel line and/or a blown fuse. |

| Fuel pump test | Park the car on flat ground, apply the parking brake, and turn off the engine. Locate the fuel pressure test port and install the pressure tester. Start the engine and record the pressure reading. Compare this to the manufacturer's specification. |

What You'll Learn

Safety precautions

Performing a fuel pressure test can be dangerous, so it is important to take the proper safety precautions. Here are some safety tips to keep in mind when testing fuel pressure:

Work in a Well-Ventilated Area

Before beginning the test, make sure you are working in a well-ventilated area. Fuel vapours are highly flammable, so adequate ventilation is crucial to reducing the risk of fire or explosion.

Wear Protective Gear

Always wear protective gear when performing a fuel pressure test. This includes safety glasses to protect your eyes from any fuel spray or vapours, and gloves to protect your hands from fuel and any sharp edges.

No Smoking

Do not smoke while performing the test, and ensure that there are no open flames or sparks in the area. Fuel is highly flammable, and any source of ignition could lead to a fire or explosion.

Use a Fire Extinguisher

Keep a fire extinguisher nearby in case of any accidents or fires. This will allow you to quickly extinguish any flames and prevent a small fire from becoming a larger one.

Check for Leaks

Before beginning the test, inspect the fuel system for any signs of leaks. If there are any leaks, address them before proceeding with the test. Leaking fuel can be a fire hazard and can also impact the accuracy of your pressure readings.

Follow Manufacturer's Instructions

Always refer to the vehicle's repair manual or manufacturer's instructions when performing a fuel pressure test. This will ensure that you are using the correct procedures and specifications for your specific vehicle.

Relieve Residual Pressure

Before installing a fuel pressure gauge, it is important to safely relieve any residual pressure in the fuel system. This will reduce the risk of fuel spraying out when you open the fuel line and help prevent injuries or fires.

Use a New Copper Sealing Gasket

If you need to open a fuel hose connection secured with a copper sealing gasket, be sure to use a new gasket when re-securing the hose after the test. This will help ensure a tight seal and prevent leaks.

Disconnect the Battery

If you are working near the battery or any electrical components, it is advisable to disconnect the battery to prevent any accidental electrical shorts. This is especially important if you are working with fuel and there is a risk of sparks or electrical arcing.

Check for Damage

Before beginning the test, inspect all components for any damage or corrosion. This includes the fuel pump, fuel lines, connectors, and wiring. If any damage is observed, address it before proceeding with the test to ensure your safety and the accuracy of the test results.

Measuring Fuel Pump Pressure: Carburetor Maintenance Guide

You may want to see also

Fuel pressure test

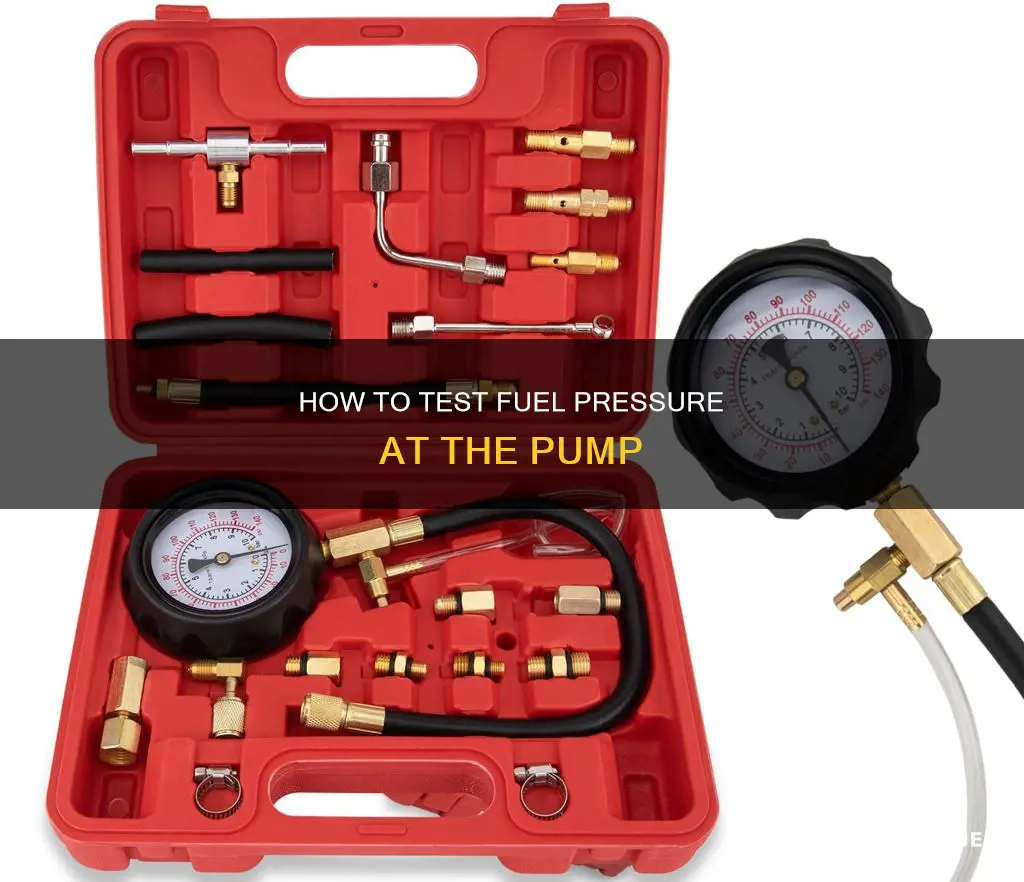

A fuel pressure test can help identify issues with your car's fuel pump, which is a critical component of your car's powertrain system. Before performing any diagnostic tests, it is important to prioritise safety. Ensure you are wearing safety glasses and gloves, working in a well-ventilated area, and refrain from smoking or creating potential sparks. Fuel vapours are highly flammable, so always have a fire extinguisher nearby.

Step 1:

Park your vehicle and apply the parking brake. Allow the engine to cool down to ensure your working area is safe. Locate the fuel pressure test port and place a rag underneath it to catch any fuel released during the test.

Step 2:

Install the pressure tester to the port. Start the engine and record the pressure reading. You may need to run the engine at a specific RPM as per the manufacturer's manual.

Step 3:

Compare the pressure reading to the manufacturer's specifications. A typical port-injected vehicle requires fuel pressure between 30 and 80 PSI. If the pressure is low, you may need to address issues with the fuel pump, fuel filter, or fuel pressure regulator.

Step 4:

If the fuel pump is supplying sufficient pressure, perform a fuel volume test to determine if the correct amount of fuel is being delivered to the fuel injectors. This can be done using a flowmeter or a glass measuring container.

Step 5:

Collect a fuel sample for five seconds with the pump running. Compare the amount of fuel delivered to the manufacturer's specifications. You may need to convert units to figure out the correct amount.

Understanding Fuel Pressure Readings:

- Zero fuel pressure indicates that the pump is dead or not receiving power. Check the fuel pump fuse and verify power to the pump with a multimeter.

- Low fuel pressure can be caused by a clogged fuel filter or a failing pump. If it is a serviceable type filter, consider replacing it. It could also be due to improper tank venting or a loose gas cap.

- High fuel pressure can be caused by a clogged or kinked fuel return line, a faulty fuel pump driver module, or a powertrain control module.

Remember, replacing a fuel pump can be costly, so it is important to carefully test your fuel system for pressure, volume, and electrical integrity before condemning the fuel pump.

Fuel Pressure Tester Kit: Essential Tools for Your Garage

You may want to see also

Using a flowmeter or glass container

Testing Fuel Pressure and Flow Using a Flowmeter or Glass Container

Testing fuel pressure and flow can be done in four steps. This process is important to carefully test before condemning the fuel pump, as replacing it can be costly if it is not the true cause of a fuel-related problem.

Step 1: Safety First

The most important thing to remember is that releasing fuel under pressure can cause fires and injuries. Therefore, safety precautions are crucial. Wear safety glasses and gloves, work in a well-ventilated area, and avoid smoking or having anything around that could cause a spark.

Step 2: Fuel Pressure

First, check the fuel pressure. Start the car and let it idle. Install a fuel pressure gauge, run the pump, and note the pressure reading. Then, compare it to the manufacturer's specification. If the pressure is low, address that issue. If the fuel pump is supplying sufficient pressure, proceed to the next step.

Step 3: Use a Flowmeter or Glass Measuring Container

The most accurate way to test fuel delivery is by using a flowmeter. However, not everyone may have access to one. An alternative method is to perform a timed fuel delivery test using a glass measuring container, as fuel can corrode or fog up plastic.

Start the car to signal the pump to run, and let it idle. Collect a fuel sample for five seconds with the pump running. The pump should deliver a specific amount of fuel within that time frame, which can be checked against the manufacturer's specifications. You might need to convert milliliters per second to gallons per hour to make this comparison.

Fuel Pressure Regulator: Why Fuel is Essential

You may want to see also

Interpreting fuel pressure readings

Understanding Fuel Pressure Readings:

- Normal Fuel Pressure Range: A typical port-injected vehicle's fuel pressure should fall between 30 and 80 PSI. However, this may vary depending on the vehicle and fuel system design. For example, direct injection fuel systems have higher pressure requirements than regular pressure fuel injection systems.

- Fuel Pressure Gauge: To check fuel pressure, a fuel pressure gauge is connected to the fuel pressure test port. This gauge displays the fuel pressure in PSI.

- Manufacturer's Specifications: It is essential to refer to the vehicle's manual or manufacturer's specifications to determine the required fuel pressure for your specific car. This information will help you identify if the fuel pressure is within the normal range.

- High Fuel Pressure: If the fuel pressure reading is higher than the manufacturer's specifications, it indicates an issue with the return line fuel components. Possible causes include a faulty fuel pressure regulator, restrictions in the return line, or faulty fuel line couplings at the fuel tank.

- Low Fuel Pressure: Fuel pressure readings lower than the manufacturer's specifications suggest a problem with the pressure line fuel components. Potential causes include a clogged or restricted fuel filter, a restriction in the pressure line, a faulty fuel pump relay, or a faulty fuel pump.

- Fuel Pressure Fluctuations: Minor fluctuations in fuel pressure readings, such as +/− 1.5 PSI, are usually not a cause for concern. However, if the fluctuations are more significant, such as 20-30%, it could indicate an issue with the fuel system or other components like a cracked vacuum hose.

- Fuel Gauge Warnings: Modern vehicles have low fuel pressure warnings, typically activated when the fuel level is low. However, sometimes, the gauge may display incorrect warnings due to faulty sensors or other issues. It is essential to refer to the owner's manual for guidance on interpreting these warnings accurately.

- Fuel Efficiency and Performance: Fuel pressure directly impacts fuel efficiency and engine performance. High fuel pressure can cause the engine to run rich, while low fuel pressure can make the engine run lean or not start at all. Therefore, maintaining correct fuel pressure is crucial for optimal vehicle performance and fuel economy.

In conclusion, interpreting fuel pressure readings involves understanding the normal fuel pressure range, using a fuel pressure gauge, and referring to manufacturer specifications. High or low fuel pressure readings indicate issues with the fuel system that require further diagnosis and potential repairs. Regularly checking and interpreting fuel pressure can help identify problems early on and ensure optimal vehicle performance and fuel efficiency.

Fuel Pressure Regulator Installation Guide for Civic Cars

You may want to see also

Testing for fuel pump failure

Another test is to use a fuel pressure gauge. Start the car and let it idle, then install a fuel pressure gauge and run the pump, noting the pressure reading. Compare this to the manufacturer's specification. If the pressure is low, further investigation is required.

A more advanced test involves using an oscilloscope and low amp clamp probe. Connecting the probe to the pump's power wire will provide a waveform pattern, which can indicate internal pump problems. A good pump will produce a pattern of even 'humps', whereas a bad pump will show jagged and uneven humps.

A simple test to check if the problem is fuel-related is to spray starter fluid into the throttle body. If the car starts and then quickly dies, it indicates a fuel system problem.

It is important to note that replacing a fuel pump can be costly, so thorough testing should be conducted to ensure the pump is the root cause of any issues.

Fixing Fuel Pressure in a 2005 Monte Carlo LT

You may want to see also

Frequently asked questions

First, park your vehicle on flat ground and apply the parking brake. Allow the engine to cool down, then locate the fuel pressure test port. Place a rag under the test port to catch any fuel that may be released when installing the pressure tester. Install the pressure tester to the port, then start the engine and record the pressure reading. Compare this to the manufacturer's specifications. If the pressure is low, you may need to replace the fuel pump.

A malfunctioning fuel pump could result in a lack of power output from the engine. This could manifest as a slow start-up, low performance, misfires, and stalling. A fuel pump malfunction could also cause excessive fuel consumption, black smoke from unburned gas, an overheating catalytic converter, and rough idling.

If you suspect your fuel pump is malfunctioning, you can take your car to a shop to have it tested. This will cost between $90.00 and $150.00 USD. Alternatively, you can borrow or purchase a fuel pump test kit and perform the test yourself.