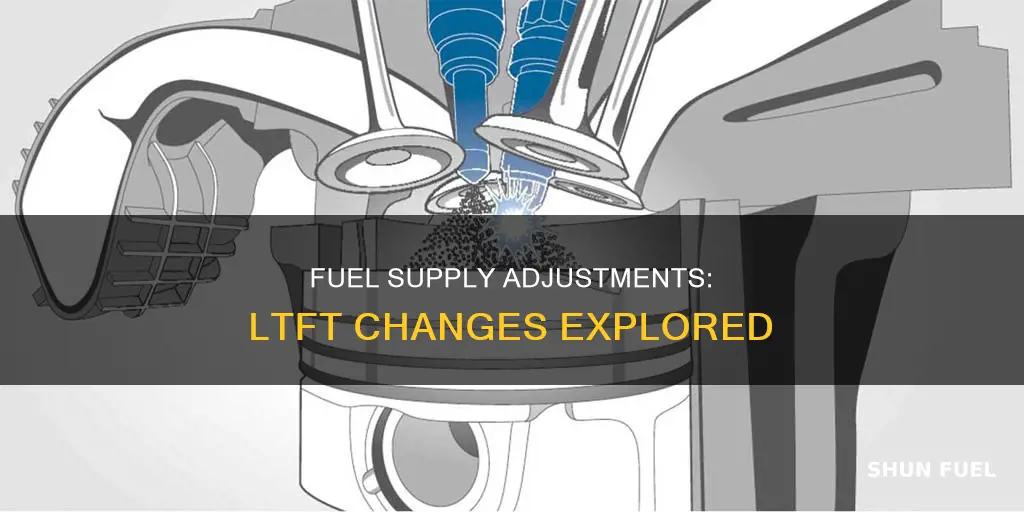

Long-term fuel trim (LTFT) is a crucial component of a vehicle's engine management system, which helps maintain optimal engine performance and efficiency. LTFT plays a significant role in diagnosing issues that may arise in the fuel delivery system, specifically those related to air-fuel ratios. LTFT values are stored in the engine control unit and are utilised every time the engine is started. They complement short-term fuel trims (STFT) by making long-term adjustments to fuel delivery based on the engine's actual performance. LTFT adjustments are made gradually over time and are typically within a range of +/-10%. However, if LTFT values exceed +/-25%, it indicates a serious problem with the engine or fuel system.

| Characteristics | Values |

|---|---|

| Type | Long-term fuel trim |

| Purpose | Diagnosing issues in the fuel delivery system |

| Calculation | Percentage (%) the PCM/ECM adjusts the calculated quantity of fuel injected into the cylinders |

| Timeframe | Changes over long periods of time |

| Storage | Permanently stored in the PCM/ECM memory |

| Range | +/-30% to +/-45% |

| Normal Range | +/-10% |

| Problem Indicator | +/-25% indicates a serious problem |

| Causes of Positive Values | Air leaks, defective fuel pump, restricted fuel flow, defective fuel pressure regulator, air leaks in the PCV system, malfunctioning MAF sensor, clogged fuel injectors, ignition misfires, damaged exhaust valve, air getting into the exhaust manifold, defective oxygen sensor or its wiring |

| Causes of Negative Values | Leaky fuel injector, defective fuel pressure regulator, restricted air intake system or clogged air filter, restricted exhaust, defective oxygen sensor or its wiring |

Oxygen sensor readings

Oxygen sensors (O2 sensors) are an important component of modern engines, playing a crucial role in maintaining optimal engine performance and reducing emissions. These sensors work by measuring the amount of oxygen in the exhaust and relaying this information to the vehicle's computer, which then adjusts the fuel mixture accordingly.

The oxygen sensor is mounted in the exhaust manifold and monitors the amount of unburned oxygen in the exhaust as it exits the engine. This information is used to determine whether the fuel mixture is burning rich (less oxygen) or lean (more oxygen). The sensor produces its own voltage, typically between 0.1 and 0.9 volts, with the reading depending on the oxygen levels in the exhaust. When the fuel mixture is rich, the sensor output voltage will be higher, typically around 0.9 volts, whereas a lean mixture will result in a lower voltage of about 0.2 volts or less. When the air-fuel mixture is balanced, the sensor reading will be around 0.45 volts.

The computer uses these oxygen sensor readings to regulate the fuel mixture through a feedback control loop. If the sensor indicates a rich mixture, the computer will respond by reducing the amount of fuel in the mixture, and vice versa. This constant adjustment between rich and lean mixtures allows the catalytic converter to operate efficiently while maintaining the overall fuel mixture balance to minimise emissions.

Additionally, oxygen sensor readings can help identify problems with the sensor itself. If the sensor reading does not fluctuate and remains steady, it could indicate a faulty or sluggish sensor that needs replacement. Contaminants accumulating on the sensor tip over time can reduce its responsiveness and accuracy, leading to increased fuel consumption and emissions.

Fuel Injector Replacement: A Quick and Easy Guide

You may want to see also

Engine wear

The ECM or PCM uses sensors to determine how much air is flowing into the engine and, along with a target air-fuel ratio, calculates how much fuel should be injected. The oxygen sensor then provides feedback on the actual air-fuel ratio, allowing the ECM or PCM to make adjustments as needed. This feedback loop helps maintain optimal engine performance and efficiency.

In the case of engine wear, the ECM or PCM may detect that the calculated fuel quantity is too high or too low and will adjust the fuel trim accordingly. For example, if there is increased carbon buildup in the engine, the oxygen sensor may detect a lean condition, as carbon buildup can reduce the amount of oxygen available for combustion. In response, the ECM or PCM will increase the fuel trim, adding more fuel to the mixture to compensate.

On the other hand, if there is a restriction in the fuel delivery system due to engine wear, such as clogged fuel injectors or a faulty fuel pump, the oxygen sensor may detect a rich condition, as there is an excess of fuel relative to the amount of air available for combustion. In this case, the ECM or PCM will decrease the fuel trim, reducing the amount of fuel injected to maintain the proper air-fuel ratio.

It is important to note that while the ECM or PCM can make adjustments to compensate for engine wear or other issues, there are limits to these adjustments. If the LTFT values exceed certain thresholds, such as +/- 25%, it may indicate a serious problem with the engine or fuel system, and diagnostic codes may be triggered to warn the vehicle's user and facilitate troubleshooting.

Changing Fuel Filters: Easy DIY or Mechanic Job?

You may want to see also

Fuel injectors

Function of Fuel Injectors

Types of Fuel Injectors

There are different types of fuel injectors available, each designed for specific applications:

- High-Performance Fuel Injectors: These injectors are designed for racing and high-performance vehicles. They offer precise fuel atomization and distribution, catering to the unique demands of racing engines.

- Vehicle-Specific Fuel Injectors: Fuel injectors are designed for specific vehicle makes and models, such as Honda Civic, Ford F150, or Toyota Camry. These injectors are engineered to fit perfectly and ensure optimal performance for each unique engine design.

Symptoms of Faulty Fuel Injectors

It is important to recognize the signs of a malfunctioning fuel injector:

- Rough engine performance

- Difficulty in starting the engine

- Engine knock or detonation

- Smoke from the tailpipe

- Poor idle

- Fuel odours inside or around the vehicle

- Oil thinning and hydro lock

Maintenance and Replacement

To maintain the performance and efficiency of your vehicle, it is crucial to keep fuel injectors in good condition. Regular cleaning and maintenance can help extend their lifespan. However, if your fuel injector is defective or clogged, it may need to be replaced. Auto parts stores offer a range of replacement fuel injectors to fit various vehicle models, ensuring a smooth and efficient engine performance.

Replacing Diesel Fuel Filters: Step-by-Step Guide for Vehicle Owners

You may want to see also

Fuel pressure

There are two main types of fuel pressure to consider: rail pressure and effective pressure (also known as differential pressure). Rail pressure refers to the pressure inside the rail, which can be measured using a fuel pressure sensor attached to the rail. Effective pressure, on the other hand, is the actual applied pressure across the injector. It is the pressure differential across the injector that ultimately determines injector flow rate.

When an engine is idling, a vacuum is created in the intake manifold. This vacuum pulls fuel out of the injectors, increasing the effective pressure. In contrast, when a vehicle is supercharged or turbocharged and in boost, the pressure inside the manifold pushes fuel back into the injector, reducing the effective pressure. Therefore, effective pressure is not solely dependent on rail pressure but is influenced by the pressure in the manifold.

To maintain a constant effective fuel pressure, some vehicles are equipped with a return-style fuel system. This system bleeds excess fuel back to the tank through a regulator, which can be vacuum/boost referenced. By adjusting the pressure in the rail based on manifold pressure, a constant effective fuel pressure can be achieved across all operating conditions. This helps to prevent a loss of effective pressure during wide-open throttle and improves fuel efficiency at idle.

However, it is important to note that return-style systems circulate fuel through a hot engine bay, which can lead to heat buildup in the fuel tank. Additionally, the effective pressure may still fluctuate in certain situations, such as when the engine is idling or at wide-open throttle.

Understanding fuel pressure and how it relates to injector flow rate is crucial for properly setting up injector characterization and achieving predictable fueling. By considering both rail pressure and effective pressure, technicians can optimise fuel system performance and diagnose any issues that may arise.

Fuel Injector Replacement: Cost and Repair Insights

You may want to see also

Fuel trim data

STFT refers to the immediate adjustments made by the engine computer based on current engine performance needs. These adjustments can vary significantly and are not as useful for diagnosing engine problems unless they occur at specific throttle positions. On the other hand, LTFT is learned over time and stored in the engine computer's memory. LTFT adjustments compensate for changes in the air-fuel ratio occurring inside the engine, and they remain relatively stable.

To access fuel trim data, a scan tool is connected to the vehicle's OBD II diagnostic connector. The engine must be running, and the scan tool is used to read system live data, which includes a list of sensor outputs and other readings called Parameter IDs (PIDs). For inline four and six-cylinder engines, there will typically be two fuel trim values, while V6 and V8 engines will have four fuel trim values, one for each cylinder bank.

The fuel trim values are displayed as percentages and indicate whether the engine computer is adding or subtracting fuel to maintain the optimal air-fuel ratio. Positive fuel trim values mean the engine computer is adding fuel to richen the mixture, while negative values indicate a reduction in fuel to lean out the mixture. These adjustments are based on feedback from the oxygen sensor, which detects whether the engine is running lean or rich.

By monitoring fuel trim data across different engine loads, technicians can identify potential issues such as vacuum leaks, fuel delivery problems, or faulty components like the MAF sensor or fuel injectors. Baselining the fuel trim data involves recording and analysing fuel trim values at idle speed, light load, moderate load, and heavy load. This information then guides further diagnostic steps and helps pinpoint the root cause of any issues.

Overall, fuel trim data is a valuable resource for technicians, providing insights into the engine's performance and facilitating efficient and accurate diagnostics and repairs.

Fixing Fuel Pressure: Replacing the Regulator

You may want to see also

Frequently asked questions

LTFT stands for Long-Term Fuel Trim. It is a key component in a vehicle's engine management system, which helps maintain optimal engine performance and efficiency. LTFT is learned over time and then stored in the ECM's keep-alive or adaptive memory.

The Electronic Control Module (ECM) or Powertrain Control Module (PCM) uses sensors to determine how much air is flowing into the engine. It then uses this data, along with a target air-fuel ratio, to calculate how much fuel to inject. The ECM or PCM uses oxygen sensor readings to find out the actual air-fuel ratio and makes adjustments to the fuel quantity to optimise combustion.

If the LTFT gets too large (around ±25%), the PCM/ECM will trigger a "MIL" warning and set Data Troubles Codes (DTCs) to help diagnose the problem. This indicates a serious issue with the engine or fuel system.