The fuel gauge in a car is an important feature that tells the driver when they need to fill up on fuel. It is part of a system that includes the fuel gauge, the circuit, and the sender, which work together to display the amount of fuel in the tank. The fuel gauge can malfunction due to a variety of issues, such as a defective sending unit, bad wiring, or a blown fuse. One question that may arise is whether fuel pressure in the tank can cause the fuel gauge to change. While fuel pressure is important for engine performance and fuel efficiency, its direct impact on the fuel gauge is less clear. Fuel pressure can indicate a problem with the fuel sending unit, but it is not the only factor that determines the accuracy of the fuel gauge.

What You'll Learn

Fuel gauge reading empty when the tank is full

A fuel gauge that reads empty when the tank is full can be caused by a variety of issues, and it is important to diagnose the problem to avoid being stranded without fuel. Here are some potential causes and solutions:

Faulty Fuel Sending Unit

The fuel sending unit, located inside the fuel tank, measures the fuel level and sends a signal to the gauge. It consists of a float, a metal rod/arm, and a variable resistor. Over time, the metal components can deteriorate due to fuel additives, corrosion, or bad fuel, causing the wrong signal to be sent to the gauge. Replacing the fuel sending unit can be complicated and costly, so consulting a professional mechanic is recommended.

Blown Fuse

A blown fuse to the fuel gauge can result from a power surge or a short circuit. Locate your car's fuse box and check if the fuse corresponding to the fuel gauge is blown. If so, replace it with a new fuse of the same amperage.

Blocked Breather in the Fuel Tank

A blocked breather hose or vent in the fuel tank can create pressure and affect the accuracy of the fuel sending unit. Inspect the breather hose or vent for any obstructions and clear or replace them if necessary.

Faulty Wiring

Loose, broken, or corroded wires between the gauge and the sending unit can cause issues. Use a multimeter to test the continuity and voltage of the wires. Inspect the connectors and terminals for any signs of damage or corrosion, and repair or replace them if needed.

Faulty Fuel Gauge

In some cases, the issue may lie with the fuel gauge itself. Remove the gauge from the dashboard and test it with a multimeter or an external power source. If it does not respond or shows an incorrect reading, you will need to replace it.

Fuel Gauge Self-Test

If your vehicle is newer, you can perform a cluster self-test to check if the issue is with the fuel gauge itself. Consult your owner's manual to determine the procedure for your specific vehicle. If the fuel gauge needle does not move as expected during the test, further diagnostics are required.

Understanding Fuel Pressure Test Drops: Causes and Implications

You may want to see also

Fuel gauge stuck on full

A fuel gauge that is stuck on full can be caused by a few issues, some more complex than others.

Firstly, a faulty fuel gauge resistor could be sending the full voltage to the fuel gauge at all times. The fuel sending unit is in constant motion when a vehicle is being used, and this can wear down the resistive material strip over time, creating an open circuit. This is a common issue, and one that will need to be fixed by a professional.

Secondly, a short in the wire going to the sender unit can cause the meter to be stuck on full. This could be caused by a pinched wire or frayed/cut insulation. This is often the case when a fuel gauge is stuck on full, and it is worth checking for any visible signs of damage to the wires.

Thirdly, a faulty ground wire to the grounding terminal could be the issue. This is a less common issue, but it is worth checking the ground connections, as rain, salt, and snow can cause a sending unit ground to fail, even if the wire is still intact.

Finally, a faulty fuel gauge could be the issue, although this is rare.

It is important to note that a non-functioning fuel gauge can be a challenge to deal with, and it is beneficial to always fill the tank and be aware of the fuel level to avoid running out of fuel.

Cold Weather's Impact on Fuel Pressure Performance

You may want to see also

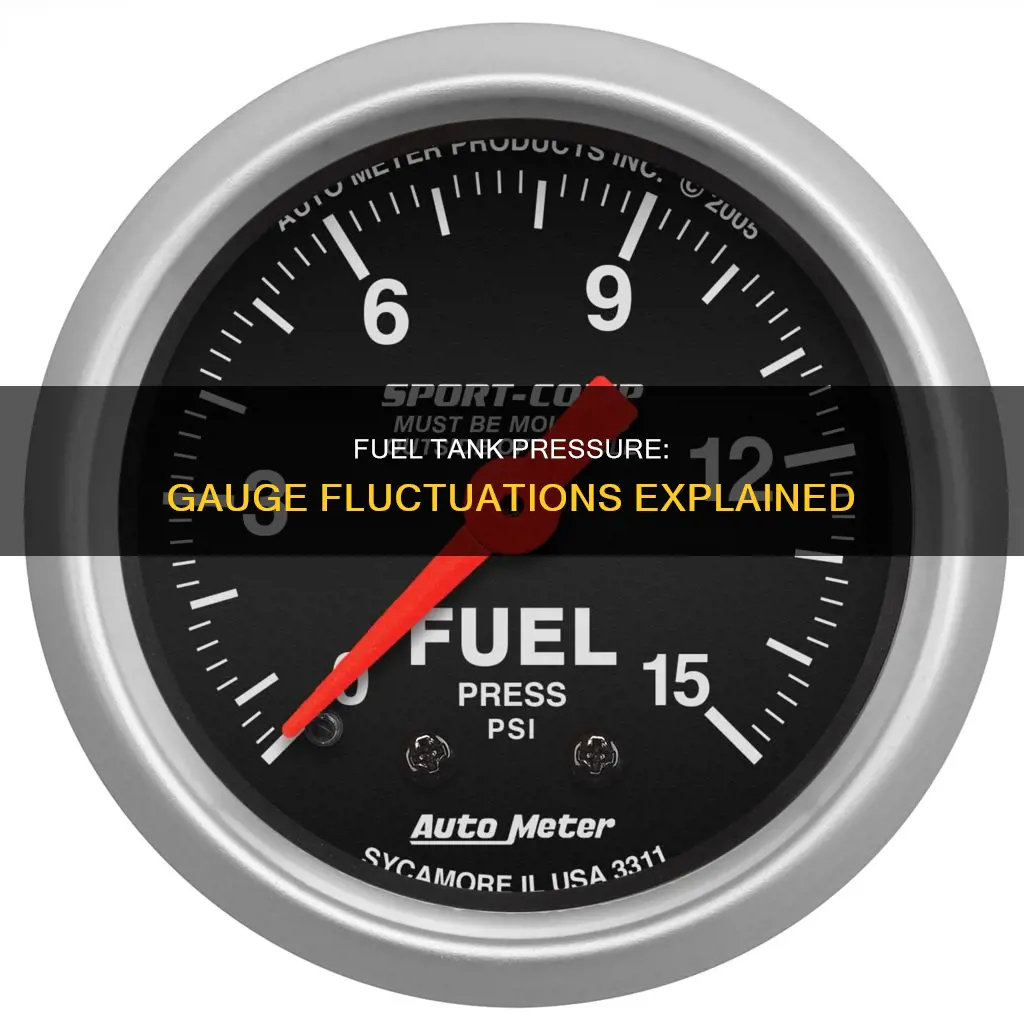

Fuel gauge fluctuations

A fluctuating fuel gauge can be a worrying issue, and there are several reasons why this might be happening.

A fuel gauge that fluctuates between empty and full may be due to a mechanical failure. The fuel sending unit float arm may be 'sticking' at certain levels, and fall back into place either naturally or with help from vehicle movement. Once the float arm falls back into place, the fuel gauge will become accurate again. This event can often be replicated, giving more evidence of mechanical failure. In some cases, a faulty fuel gauge could be the issue.

The fuel sending unit is used to measure the amount of fuel in the fuel tank and communicate the fuel level to the fuel gauge on the dashboard. The sending unit is constantly monitoring the level of fuel in the tank, but this constant use means that it is prone to wear. If the contacts wear out, the circuits can remain open, and the fuel gauge might think the voltage feedback means that the tank is either empty or full.

The fuel sending unit is located in the gas tank and measures the fuel tank level. Some sending units are attached to the fuel pump assembly, while others are stand-alone units, but both are made up of the same three components: a float, a metal rod/arm, and a variable resistor. These components work together to measure the vehicle’s fuel level and relay the information to the gas gauge.

The float, which is made of a buoyant composite or foam, floats on top of the fuel in the tank. The float is connected by a thin metal rod to a contact inside the variable resistor. A resistor is an electrical device that resists the flow of electricity, and a variable resistor has the ability to adjust the amount of resistance voltage encounters by sliding a contact (wiper) over a resistive element. The wiper is connected to the fuel gauge either directly by wire or indirectly to an electronic device that communicates with the fuel gauge. In a fuel sending unit, the variable resistor receives power via a small coil from the vehicle’s battery, which is used as the baseline signal.

As the fuel level and the float lower in the tank, the metal rod connected to the float either moves the wiper further or closer to the ground, which either restricts or increases the amount of electric current being sent to the fuel gauge. The fuel gauge display drops from full according to the resistance change.

If you are experiencing issues with your fuel gauge, there are some tests you can perform to diagnose the problem.

Firstly, determine the instrument cluster self-test procedure by consulting your owner's manual. Once you have activated the cluster self-test procedure, perform it. If your vehicle is from before the 1990s, it is unlikely that this procedure can be done. In newer cars, this often involves turning the headlights on and off a certain number of times and pressing the odometer button, while in older cars it involves turning the ignition on and off a few times. If the fuel gauge needle does not go through a full sweep during the cluster self-test process, the issue is with the fuel gauge directly. If the needle performs the sweep as intended, further tests are required to properly diagnose the problem.

The next step is to check the fuses. If you are experiencing issues with more than one gauge on your vehicle, the culprit may be a fuse. If the fuse for the instrument panel has blown, replace it and turn on the car. If the fuel gauge issue persists, run the cluster test again.

Testing the wiring is not particularly difficult, but it can be time-consuming. Start at the gas tank and inspect the wiring harness. Also, check the ground connections, which can become corroded due to exposure to rain, salt, and snow. Remove any corroded connections, clean them, and re-attach. Visually inspect the wiring as any break or damage to the sending unit wire or ground will cause a problem with the gauge. In most cases, to gain access to the fuel tank sending unit mount/fuel pump mounting hole, you will need to drop the gas tank down. Ensure that there is minimal gas in the vehicle or that it has been siphoned out. Most gas gauge issues can be traced to an issue with the wiring near the tank or with the sending unit itself.

If your wiring and fuse tests pass, the next step is to remove the fuel sending unit/fuel pump assembly from the tank and inspect it. Sometimes, the arm or float will be broken, or the wiring leading up to and out of the sending unit will be damaged. On older vehicles with a 1-wire sending unit, resistance can be tested easily. Most older sending units are a "0-30" or "0-60" ohm sending unit, meaning that when the tank is empty, the resistance will read 0 ohms, and when full, it will read 30 or 60 ohms. To test this, put your multimeter to ohms (resistance) setting, and touch one probe to the sending terminal and the other to the ground. Slowly move the float up and down, and you should see the resistance change on the multimeter. If there is no change, the sending unit is faulty. On newer sending units that incorporate the fuel pump into the assembly, this test is more difficult, if not impossible, to perform, but test procedures can often be found online. If the sending unit is suspected to be faulty on a newer vehicle, the entire fuel pump assembly must usually be replaced.

Other Fuel Gauge Issues

A fuel gauge that reads empty when the tank is full may be caused by the float separating from the arm, causing the rest of the components in the fuel sending unit to stop completely. In some cases, a faulty resistor can also cause the gauge to read empty by restricting the signal completely. Corroded wires, especially in the case of a fuel sending unit located on the fuel pump, can stop voltage from reaching either the source or the fuel gauge.

A fuel gauge that only reads full may be caused by a faulty fuel gauge resistor sending the full voltage to the fuel gauge at all times. The fuel sending unit is constantly in motion when a vehicle regularly uses fuel, which causes constant movement of the wiper in the variable resistor. Over time, this can

Fuel Pressure Regulator: LS1Tech Mounting Location Guide

You may want to see also

Fuel gauge internal circuit failure

A fuel gauge is an essential component of a car, as it tells the driver about the amount of fuel available. An inaccurate fuel gauge can lead to dangerous circumstances, such as running out of fuel in a remote location.

The fuel gauge system can be divided into three parts: the sender, the gauge, and the circuit. An issue with any of these components can cause the fuel gauge to malfunction. The most common cause of a faulty fuel gauge is a problem with the sending unit. This unit is in constant motion when the car is moving, and over time, the contacts can wear off, leading to an open circuit. This, in turn, can cause the fuel gauge to register voltage feedback as FULL or EMPTY, resulting in an inaccurate reading.

Another potential issue is a faulty internal circuit within the fuel gauge itself. In this case, only one section of the gauge may function, such as between FULL and HALF or HALF and EMPTY. If there is an open circuit, the sensor will likely be stuck on EMPTY. Additionally, loose connections and corrosion can also cause fuel gauge problems, as the gauge is normally exposed to these elements.

To diagnose a faulty fuel gauge, you can perform an instrument cluster self-test, which is available in many modern vehicles. This test involves turning on and off the headlights and pressing the odometer button a certain number of times. During this test, the fuel gauge needle should sweep smoothly from EMPTY to FULL. If it does not, there is an issue with either the fuel gauge or the sending unit.

If the fuel gauge is functioning correctly during the self-test, the next step is to check the fuses. A blown fuse for the instrument panel may cause the fuel gauge to malfunction. After replacing the fuse, turn on the car and run the cluster test again.

Testing the wiring and grounding is also important, as issues with the wiring near the tank or with the sending unit are common causes of fuel gauge problems. Corroded wires, especially in the case of a sending unit located on the fuel pump, can interrupt the voltage supply to the fuel gauge. Therefore, it is crucial to visually inspect the wiring for any damage or breaks and clean or replace the wires if necessary.

In conclusion, a fuel gauge internal circuit failure can be caused by various factors, including sending unit failure, open circuits, loose connections, and corrosion. To diagnose and fix the issue, it is recommended to follow the steps outlined above, starting with the instrument cluster self-test and progressing to checking fuses, wiring, and grounding.

Tire Pressure: Fuel Economy's Best Friend

You may want to see also

Malfunctioning instrument cluster

A malfunctioning instrument cluster can manifest in various ways, indicating trouble within your vehicle's critical dashboard display. Here are some common signs of a failing instrument cluster:

- Inaccurate readings: You might notice that your speedometer reads too high or too low, the fuel gauge doesn't reflect the actual fuel level, or the engine temperature gauge behaves erratically. For instance, your fuel gauge might read empty when the tank is full, or vice versa.

- Dim or flickering lights: Dim or flickering lights on the instrument cluster suggest an issue with the bulbs or electrical connections. This can make it challenging to read the gauges, especially after dark.

- Total cluster failure: The instrument cluster may stop working temporarily or permanently.

- Warning lights and error messages: You might see warning lights on your dashboard that are not supposed to be illuminated, or you might receive error messages unrelated to any genuine issues with your vehicle.

- Audible indicator failures: Warning signals, such as the key-in-ignition alarm, may be absent when they should sound.

- Defective turn signal indicators: Malfunctioning turn signal indicators can hinder your ability to signal your intentions to other drivers.

If you suspect a malfunctioning instrument cluster, it is crucial to address the issue promptly. Here are some steps you can take:

- Consult your owner's manual to determine the instrument cluster self-test procedure for your specific vehicle model and age. Perform the cluster self-test. If the fuel gauge needle does not move as intended, the issue is likely with the fuel gauge itself.

- Check the fuses, especially if multiple gauges in your vehicle are affected. Replace any blown fuses for the instrument panel.

- Test the wiring, starting at the gas tank. Inspect the wiring harness at the gas tank, which handles power for the fuel pump and sending unit. Ensure that the ground connections are secure and free from corrosion.

- Visually inspect the sending unit and test its resistance using a multimeter. If the arm or float is broken, or the wiring is damaged, you may need to replace the sending unit.

- Test the fuel gauge itself using a multimeter. Different gauges have different testing methods, so refer to a repair manual or online resource for specific instructions.

Pressure Vacuum Fuel Caps: Performance Worth the Price?

You may want to see also

Frequently asked questions

The most common reason a fuel gauge is not working or is inaccurate is due to a bad fuel level sending unit. It can also be caused by bad wirings between the gauge and fuel sender or a blown fuse to the fuel gauge. The fuel gauge itself could also be damaged.

The fuel gauge contains three vital parts that work together seamlessly. The gauge that you see relies on the circuit and sender for information. If any one of these parts fails, the gauge could read wrong.

If your vehicle is experiencing any of the issues listed above, there are tests that can be done to confirm the issue. It is recommended to try all tests before getting into the gas tank and replacing a sending unit that could still be functional. Sometimes the fix can be as simple as changing an instrument cluster fuse.