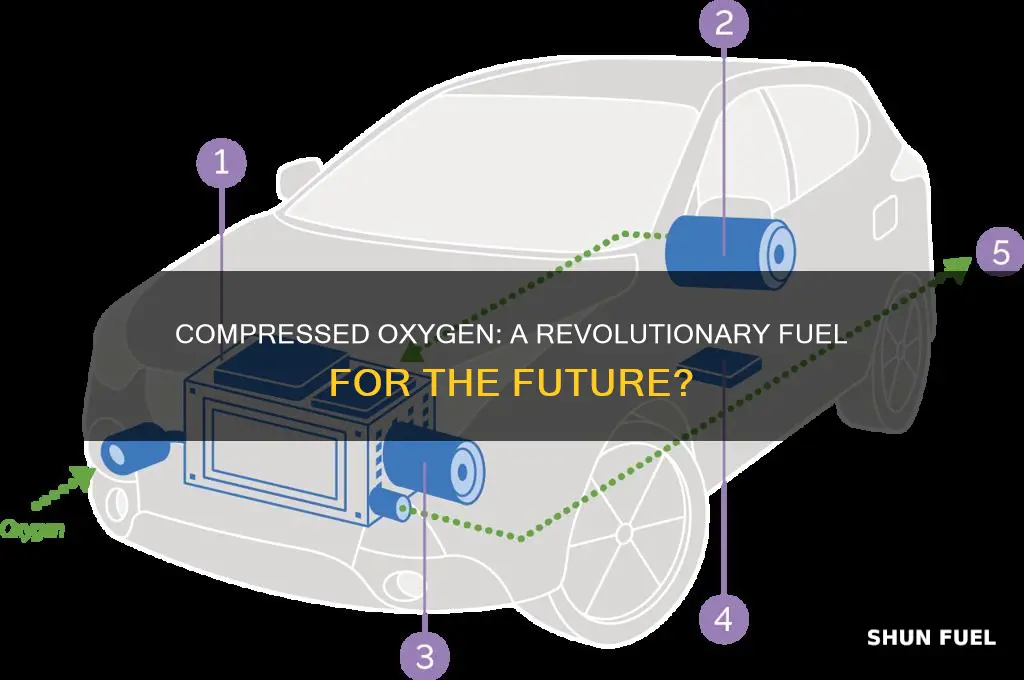

Compressed oxygen, a byproduct of industrial processes, has sparked curiosity in the automotive industry as a potential alternative fuel. While it is not a conventional fuel source, the idea of using compressed oxygen in vehicles has gained traction due to its high energy density and the potential for reduced emissions. This concept raises intriguing questions about the feasibility and implications of incorporating compressed oxygen as a fuel in cars, prompting further exploration of innovative energy solutions.

| Characteristics | Values |

|---|---|

| Energy Density | Compressed oxygen has a higher energy density compared to gasoline, making it a potentially powerful fuel source. |

| Combustion Efficiency | It can lead to more efficient combustion, resulting in higher power output and reduced emissions. |

| Environmental Impact | Using compressed oxygen as a fuel could significantly reduce carbon emissions and improve air quality. |

| Storage and Handling | Compressed oxygen requires specialized storage tanks and handling procedures due to its high pressure and potential hazards. |

| Cost and Availability | The cost of compressed oxygen and the infrastructure needed for refueling stations might be a challenge for widespread adoption. |

| Safety Considerations | Handling compressed oxygen poses safety risks, including the potential for explosions and the need for strict safety protocols. |

| Performance in Engines | Oxygen-enriched combustion can improve engine performance, but it may also require engine modifications to optimize fuel-air mixture. |

| Research and Development | Ongoing research aims to optimize the use of compressed oxygen in vehicles, addressing challenges related to storage, safety, and engine compatibility. |

What You'll Learn

- Energy Density: Compressed oxygen's energy density compared to gasoline

- Combustion Efficiency: Oxygen's combustion efficiency with different fuels

- Storage Challenges: Challenges of storing compressed oxygen in cars

- Engine Modifications: Required engine modifications for oxygen fuel combustion

- Safety Considerations: Safety concerns of using compressed oxygen as fuel

Energy Density: Compressed oxygen's energy density compared to gasoline

The concept of using compressed oxygen as a fuel in vehicles is an intriguing one, especially when considering its energy density. Energy density is a critical factor in determining the feasibility of any fuel source, as it directly impacts the vehicle's range and performance. When comparing compressed oxygen to gasoline, the energy density of the latter is significantly higher, making it a more practical choice for conventional internal combustion engines.

Gasoline, a well-established fuel, boasts an energy density of approximately 46 megajoules per liter (MJ/L). This high energy density allows gasoline-powered vehicles to travel long distances on a single tank of fuel. In contrast, compressed oxygen, when stored at high pressures, has an energy density of around 1.4 MJ/L. While this is still a substantial amount of energy, it is notably lower than that of gasoline.

The lower energy density of compressed oxygen presents both advantages and challenges. On the positive side, it suggests that vehicles using compressed oxygen might require smaller fuel tanks, potentially reducing the overall weight and size of the vehicle. However, this also means that vehicles would need to be refueled more frequently, which could impact convenience and the overall driving experience.

To make compressed oxygen a viable fuel option, advancements in storage technology and fuel cell efficiency are crucial. Researchers are exploring ways to increase the energy density of compressed oxygen, such as through the use of advanced materials and storage systems. For instance, developing high-pressure tanks with improved structural integrity could enable higher energy storage densities. Additionally, optimizing fuel cell designs to enhance efficiency can help overcome the energy density challenge.

In summary, while compressed oxygen has a lower energy density compared to gasoline, ongoing research and development efforts aim to address this issue. By focusing on enhancing storage technologies and fuel cell efficiency, the potential for compressed oxygen to become a practical and sustainable fuel source for vehicles may be realized, offering an alternative to traditional gasoline-powered engines.

The Ultimate Guide to the Most Fuel-Efficient Cars on the Market

You may want to see also

Combustion Efficiency: Oxygen's combustion efficiency with different fuels

The concept of using compressed oxygen as a fuel in vehicles is an intriguing one, and it's important to understand the combustion efficiency of oxygen when compared to other fuels. When considering the combustion process, oxygen's role is crucial as it serves as the oxidizer, enabling the complete burning of other substances. In the context of automotive applications, the efficiency of combustion directly impacts performance, fuel economy, and emissions.

Oxygen, being a highly reactive element, has a unique combustion characteristic. When compressed and used as a fuel, it can lead to a more efficient combustion process. The combustion efficiency of oxygen is primarily determined by its ability to support rapid and complete burning. In a typical internal combustion engine, the air-fuel mixture is ignited, and the combustion process relies on the presence of oxygen in the air. However, compressed oxygen, when injected directly into the engine, can enhance this process.

The combustion efficiency of oxygen is often compared to that of conventional fuels like gasoline or diesel. In a study comparing the combustion of compressed oxygen with gasoline, it was found that oxygen-based combustion can lead to higher efficiency. This is because oxygen has a higher specific heat capacity, allowing for more rapid and complete burning. As a result, the combustion process can be more efficient, leading to improved power output and reduced fuel consumption.

Furthermore, the use of compressed oxygen as a fuel can have environmental benefits. With its high combustion efficiency, oxygen-based combustion can potentially reduce the formation of harmful pollutants, such as carbon monoxide and unburned hydrocarbons. This is particularly significant in the context of reducing vehicle emissions and improving air quality. However, it is essential to note that the infrastructure and technology required to implement compressed oxygen fuel systems in cars are still under development.

In summary, the combustion efficiency of oxygen as a fuel in cars is a promising area of research. Its ability to support rapid and complete burning can lead to improved performance and reduced emissions. While there are challenges to implementing this technology, the potential benefits in terms of combustion efficiency and environmental impact make it an exciting prospect for the future of automotive fuel systems.

Flexible Fuel Cars: The Ultimate Guide to Multifuel Vehicles

You may want to see also

Storage Challenges: Challenges of storing compressed oxygen in cars

The idea of using compressed oxygen as a fuel in vehicles is an intriguing concept, but it presents several storage challenges that need to be addressed for practical implementation. One of the primary concerns is the physical space required to store the compressed oxygen tanks. These tanks need to be compact and lightweight to fit within the limited interior space of a car without compromising on passenger comfort or cargo capacity. The design of the storage system becomes crucial, requiring innovative solutions to maximize space utilization while ensuring the structural integrity and safety of the vehicle.

Another challenge lies in the pressure management and safety aspects. Compressed oxygen tanks must be designed to withstand high-pressure conditions, which can be technically demanding. The materials used for construction need to be carefully selected to handle the stress and potential hazards associated with compressed gases. Additionally, safety mechanisms, such as pressure relief valves and emergency shut-off systems, are essential to prevent accidents and ensure the well-being of passengers and pedestrians in the event of a malfunction.

Furthermore, the weight of the oxygen storage system is a critical factor. The tanks and associated equipment should be as lightweight as possible to minimize the overall vehicle weight, which directly impacts fuel efficiency and performance. Balancing the need for structural support and safety with the desire for a lightweight design is a complex task that requires careful engineering and material selection.

The maintenance and longevity of the storage system are also important considerations. Regular inspections and maintenance routines may be necessary to ensure the safety and efficiency of the compressed oxygen fuel system. This includes monitoring the condition of the tanks, checking for leaks, and verifying the functionality of safety features. Over time, the system's performance and reliability must be maintained to provide a consistent and safe fuel source for the vehicle.

In summary, while the concept of compressed oxygen as a fuel in cars holds promise, the storage challenges are significant. These include space constraints, pressure management, safety considerations, and the need for lightweight, durable storage systems. Overcoming these obstacles will be essential in making compressed oxygen a viable and safe alternative fuel option for the automotive industry.

Indy Cars: Fuel Efficiency Unveiled

You may want to see also

Engine Modifications: Required engine modifications for oxygen fuel combustion

The concept of using compressed oxygen as a fuel in automobiles is an intriguing one, and it involves significant engine modifications to accommodate this alternative fuel source. When considering the combustion of oxygen fuel, several key engine components require attention to ensure efficient and safe operation.

One of the primary modifications involves the engine's intake system. Since oxygen fuel is highly concentrated, the engine needs to draw in a precise amount of air-fuel mixture. This often necessitates the installation of a mass airflow (MAF) sensor, which measures the volume of air entering the engine. The MAF sensor provides real-time data to the engine's electronic control unit (ECU), allowing for accurate fuel injection and combustion timing adjustments. Additionally, the intake manifold may need to be modified to ensure proper air distribution and to accommodate the higher oxygen content.

The combustion chamber itself undergoes substantial changes. Oxygen fuel burns at a much higher temperature compared to gasoline or diesel, requiring a redesign of the chamber to withstand these extreme conditions. This includes using materials with excellent heat resistance, such as advanced alloys or ceramic coatings. The shape and size of the combustion chamber may also be altered to promote efficient combustion and reduce the risk of engine knock.

Another critical aspect is the fuel injection system. Oxygen fuel requires precise control over the fuel-air mixture, often demanding a more sophisticated injection system. This could involve the use of electronic injectors that can deliver fuel in micro-droplet sizes, ensuring complete combustion. The ECU plays a vital role here, as it needs to adjust fuel injection timing and quantity based on the MAF sensor data, maintaining an optimal air-fuel ratio for efficient combustion.

Furthermore, the engine's ignition system must be capable of generating a powerful spark to ignite the oxygen-rich mixture. This might involve upgrading to a high-performance ignition coil and spark plugs designed to handle the higher combustion temperatures. The engine's timing system may also require calibration to optimize the timing of the spark, ensuring efficient combustion and power output.

In summary, engine modifications for oxygen fuel combustion are extensive and require careful consideration of various components. From the intake system to the combustion chamber, fuel injection, and ignition, each part must be tailored to handle the unique characteristics of oxygen fuel. These modifications aim to maximize efficiency, power, and safety while providing a viable alternative to traditional gasoline or diesel engines.

Motorcycles vs. Cars: Fuel Efficiency Showdown

You may want to see also

Safety Considerations: Safety concerns of using compressed oxygen as fuel

The concept of using compressed oxygen as a fuel source for vehicles is an intriguing one, but it raises several safety concerns that need to be carefully addressed. One of the primary issues is the high pressure at which oxygen is stored, typically in cylinders. This compressed state requires specialized containers and handling procedures to prevent accidents. If not managed properly, the release of compressed oxygen could lead to explosions or rapid pressure buildup, posing significant risks to both the vehicle and its occupants.

In the event of a collision or impact, the integrity of the oxygen storage system becomes critical. The containers must be designed to withstand such forces without compromising the oxygen's integrity or releasing it prematurely. Any damage to the container could result in the oxygen escaping, potentially igniting and causing a fire hazard. Therefore, rigorous testing and engineering standards are essential to ensure the safety of such a system.

Another safety consideration is the potential for fire or explosion during refueling or maintenance. Oxygen, being highly reactive, can accelerate combustion when mixed with flammable substances. Refueling procedures would need to be meticulously designed to prevent sparks or heat sources that could initiate a fire. Maintenance workers would also require specialized training to handle the equipment safely.

Furthermore, the use of compressed oxygen as a fuel source could impact the overall safety of the vehicle's design. The placement of oxygen tanks and associated components would need to be carefully planned to minimize the risk of damage or interference with other vehicle systems. This includes considering the location of fuel tanks, ignition sources, and electrical systems to prevent any potential hazards.

Lastly, the infrastructure and regulations surrounding the distribution and use of compressed oxygen would need to be established. This includes the development of safe refueling stations, the implementation of standardized procedures, and the training of personnel to handle and manage this unique fuel source. Addressing these safety considerations is crucial to making compressed oxygen a viable and safe alternative fuel for vehicles.

Green Energy, Clean Drive: Are Fuel Cell Cars the Future?

You may want to see also

Frequently asked questions

While compressed oxygen is a highly flammable gas, it is not typically used as a fuel source in conventional internal combustion engines. The primary reason is that oxygen itself does not burn; it acts as an oxidizer, enabling combustion when combined with a fuel like gasoline or diesel. However, in a process known as fuel cell technology, compressed oxygen can be utilized in a different manner. Fuel cells produce electricity through a chemical reaction between oxygen and a fuel, typically hydrogen, resulting in a more efficient and environmentally friendly power source for vehicles.

Fuel cells offer several benefits over traditional combustion engines. Firstly, they are highly efficient, converting a significant portion of the chemical energy in the fuel into electricity, resulting in reduced energy wastage. Secondly, fuel cells produce electricity through an electrochemical reaction, emitting only water and warm air, making them a cleaner and greener alternative to internal combustion engines. This technology can potentially reduce greenhouse gas emissions and improve air quality.

One of the main challenges is the storage and handling of compressed oxygen. Oxygen tanks need to be designed to withstand high pressure and potential hazards associated with compressed gases. Additionally, the infrastructure for refueling fuel cell vehicles is still developing, and the cost of fuel cells and their components can be relatively high compared to conventional engines. Despite these challenges, ongoing research and development efforts are focused on improving the technology, making it more accessible and cost-effective for widespread adoption in the automotive industry.